Di-amidoxime group containing modified silica gel adsorbent and preparation method thereof

A bisamidoxime and silica gel adsorption technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as difficult separation, low grafting degree, and insufficient specific surface area, and achieve Improved adsorption performance, high mechanical strength, and good regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

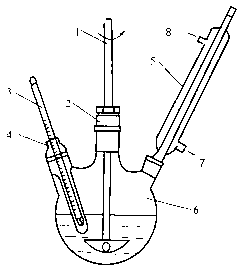

[0032] combine figure 1 , a kind of preparation method that the present invention proposes containing the modified silica gel adsorbent of bisamidoxime group, comprises the following steps:

[0033] Step 1, activation: put 30g of 100-200 mesh column chromatography silica gel in 150mL of 5% methanesulfonic acid solution, reflux at 90°C and keep stirring for 4 hours. After the reaction is completed, rinse with distilled water repeatedly Until the washing liquid is neutral, dry it under vacuum at 50°C for 24 hours;

[0034] Step 2, impregnation: Add 10g of the activated silica gel obtained in Step 1 into 150mL of KH550 in toluene solution, where the volume concentration of KH550 is 10%, reflux at 70°C and keep stirring for 24 hours, filter to get coarse particles, and then use Extract with toluene in a Soxhlet extractor for 24 hours to remove unreacted KH550 on the surface of silica gel to obtain impregnated particles;

[0035] Step 3, drying: vacuum-dry the impregnated granul...

Embodiment 1

[0041] Step 1, activation: put 30g of 100-200 mesh column chromatography silica gel in 150mL of 5% methanesulfonic acid solution, reflux at 90°C and keep stirring for 4 hours. After the reaction is completed, rinse with distilled water repeatedly Until the washing liquid is neutral, dry it under vacuum at 50°C for 24 hours;

[0042] Step 2, impregnation: Add 10g of the activated silica gel obtained in Step 1 into 150mL of KH550 in toluene solution, where the volume concentration of KH550 is 10%, reflux at 70°C and keep stirring for 24 hours, filter to get coarse particles, and then use Extract with toluene in a Soxhlet extractor for 24 hours to remove unreacted KH550 on the surface of silica gel to obtain impregnated particles;

[0043] Step 3, drying: vacuum-dry the impregnated granules obtained in Step 2 at 50° C. for 24 hours to obtain dry granules;

[0044] Step four, modification:

[0045] (1) Add 5g of the dried granules obtained in Step 3 to 100mL of acrylonitrile in ...

Embodiment 2

[0049] Repeat steps one to three in Example 1

[0050] Step four, modification:

[0051] (1) Add 5g of the dried granules obtained in step 3 to 100mL of acrylonitrile in N,N-dimethylformamide (DMF) solution, where the volume concentration of acrylonitrile is 15%, and then blow nitrogen into the bottle to remove Then add 0.1g initiator azobisisobutyronitrile, condense and reflux at 75°C and continue to stir for 5 hours. The agent was extracted in a Soxhlet extractor for 24 hours to remove unreacted acrylonitrile on the surface of the silica gel to obtain impregnated primary modified particles, and vacuum dried at 50°C for 24 hours to obtain dried primary modified particles;

[0052] (2) Mix 20mL of hydroxylamine hydrochloride solution with a concentration of 1mol / L and 20mL of sodium carbonate solution with a concentration of 1mol / L, then add 1g of the modified particles obtained in step 4 (1), and then blow in nitrogen, Remove the air in the bottle, reflux at 70°C and contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com