Transverse power component with high K insulating regions

A technology of lateral power devices and insulating regions, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effects of improving breakdown voltage, optimizing surface electric field, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

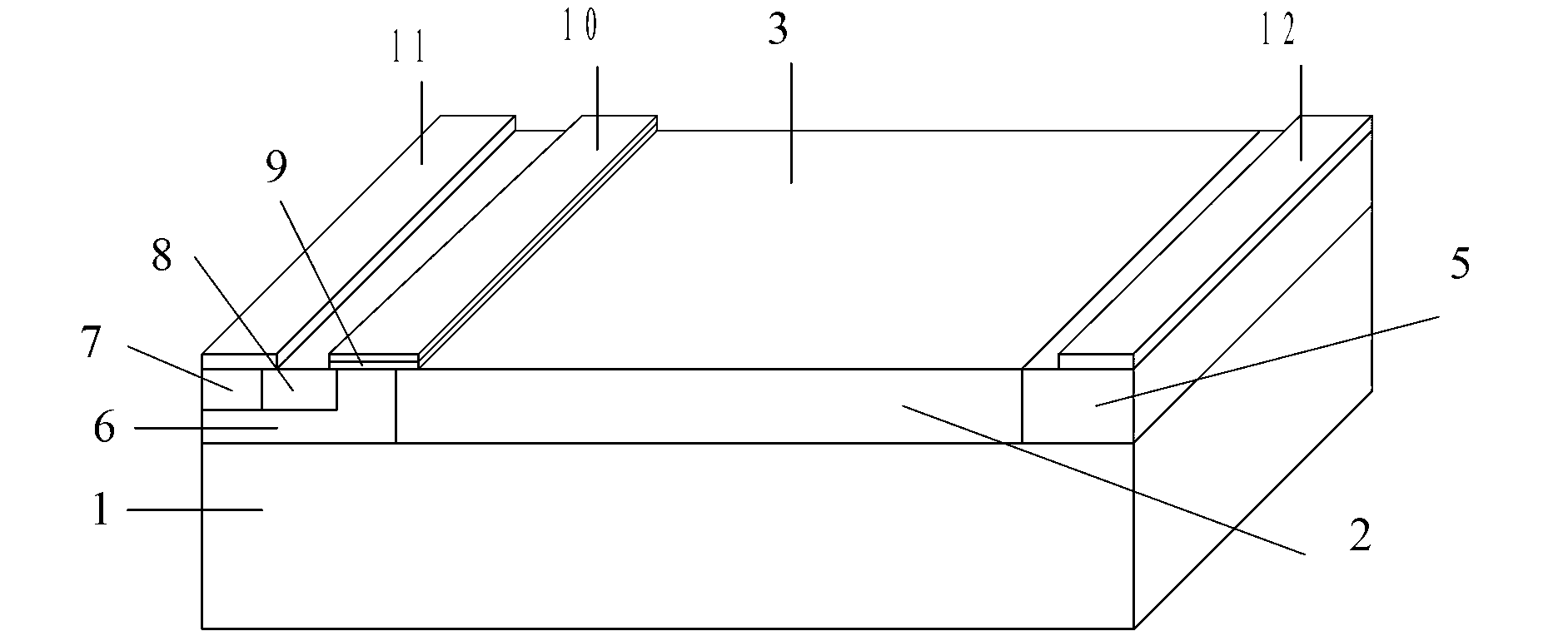

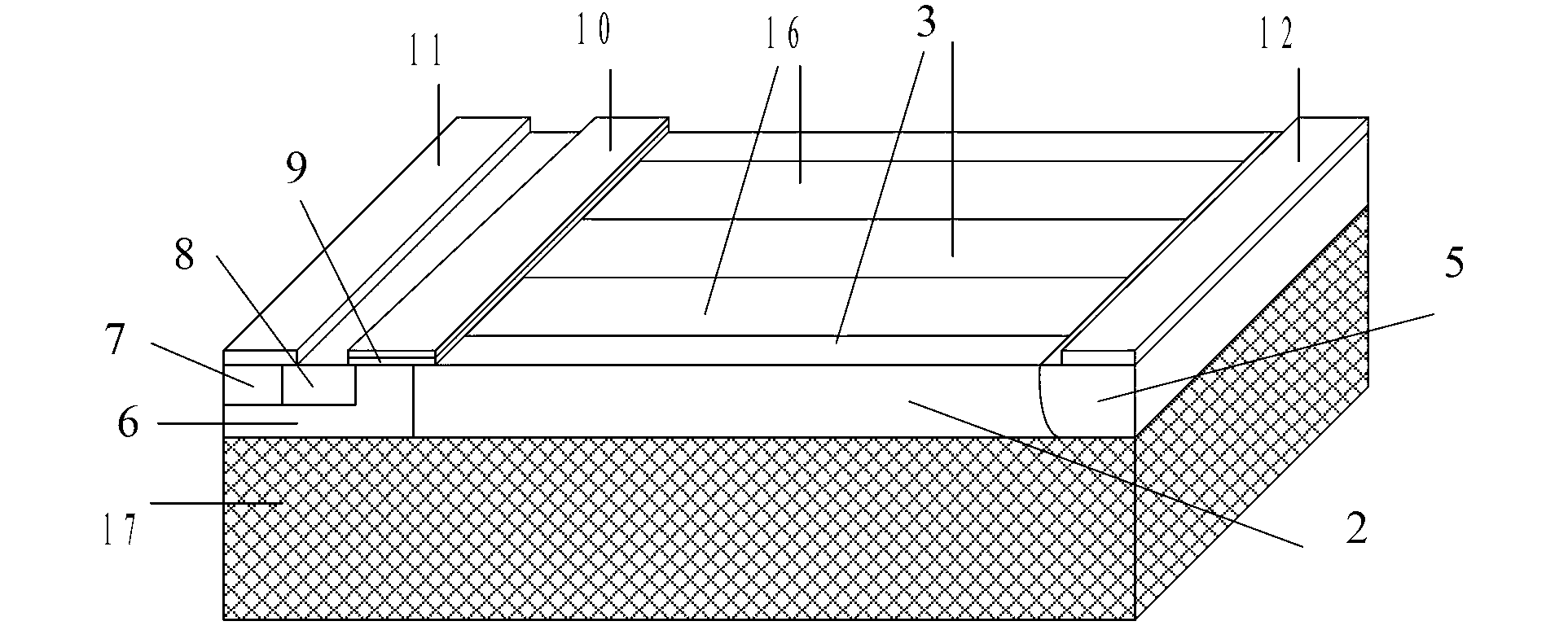

[0029] Figure 5 It is a three-dimensional view of one of the lateral power devices with a high-K insulating region provided by the present invention, and its process flow. As can be seen from the figure, it is to etch trenches with corresponding patterns on the epitaxial layer 2, and then fill the trenches with an insulating material with a high dielectric constant, thereby forming alternately arranged N-type semiconductor regions 3 and high K insulator region 4. Next, a semiconductor body region 6, a semiconductor drain region 5, a semiconductor source region 8 and a semiconductor body contact region 7 in the semiconductor body region, a gate oxide layer 9, a gate metal 10, and a source metal are formed in the epitaxial layer using a conventional LDMOS process. 11, Drain metal 12.

[0030] In the design process, according to the specific situation, certain flexible designs can be carried out under the condition that the basic structure remains unchanged, for example:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com