Hydraulic pipeline leakage online detecting method and device

A technology of hydraulic pipeline and detection method, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problems of waste of resources, environmental pollution, and waste of oil products, etc. The effect of avoiding fire, avoiding the expansion of accidents, reducing environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

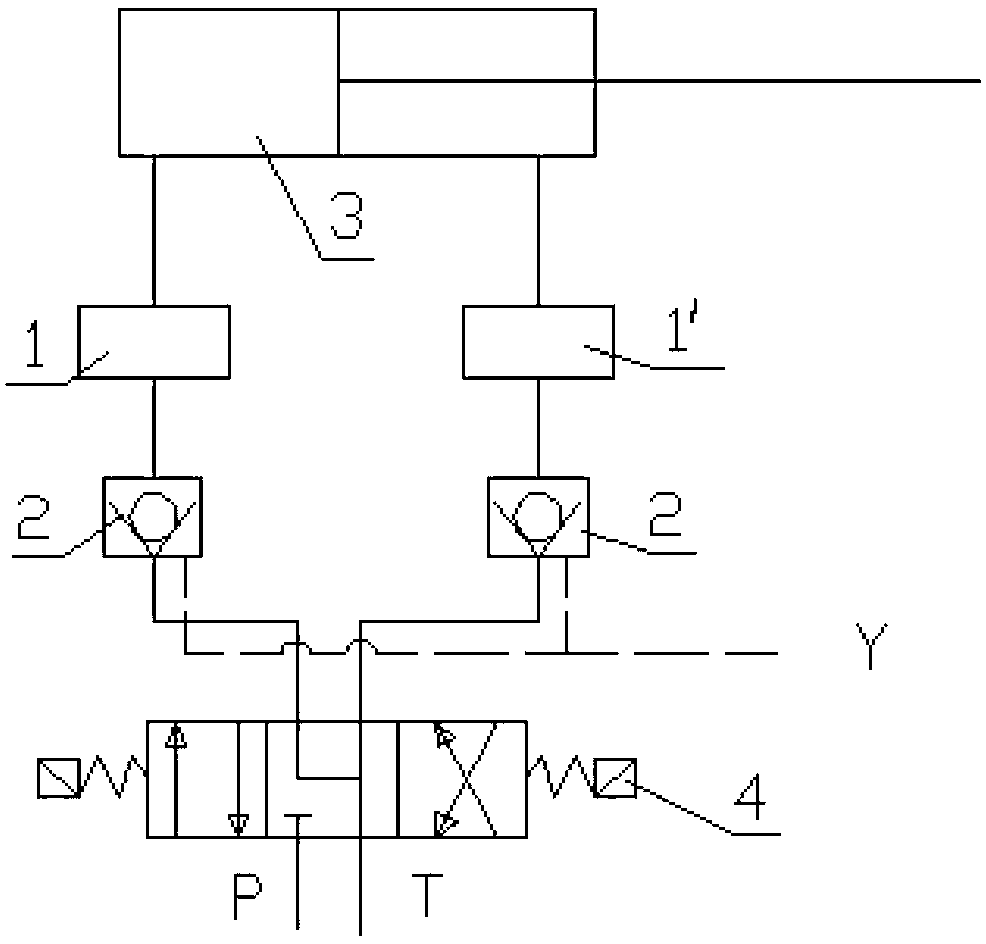

[0019] See figure 1 , is a structural block diagram of an embodiment of an on-line detection device for hydraulic pipeline leakage in the present invention, including a flowmeter 1, the flowmeter 1 is arranged on the oil inlet pipeline of the hydraulic cylinder 3, and the 4-20mA signal output terminal of the flowmeter 1 is connected to the remote computer. The flow meter 1 is closely connected to the outlet port of the one-way valve 2 downstream of the electromagnetic (liquid) reversing valve 4 .

[0020] The present invention measures the oil intake of the hydraulic cylinder and judges the difference between the oil intake and the reference value in real time based on the oil intake when the hydraulic cylinder is qualified, as the basis for the leakage of the hydraulic cylinder and its oil intake pipeline. Taking the two-way hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com