Alcohol group steam generator

A steam generator and alcohol-based technology, which is applied in steam generation, steam boilers, fire tube steam boilers, etc., can solve the problems of slow steam production, low heat production efficiency, and high cost of use, so as to achieve fast heat start and increase production efficiency. Effect of thermal efficiency and pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

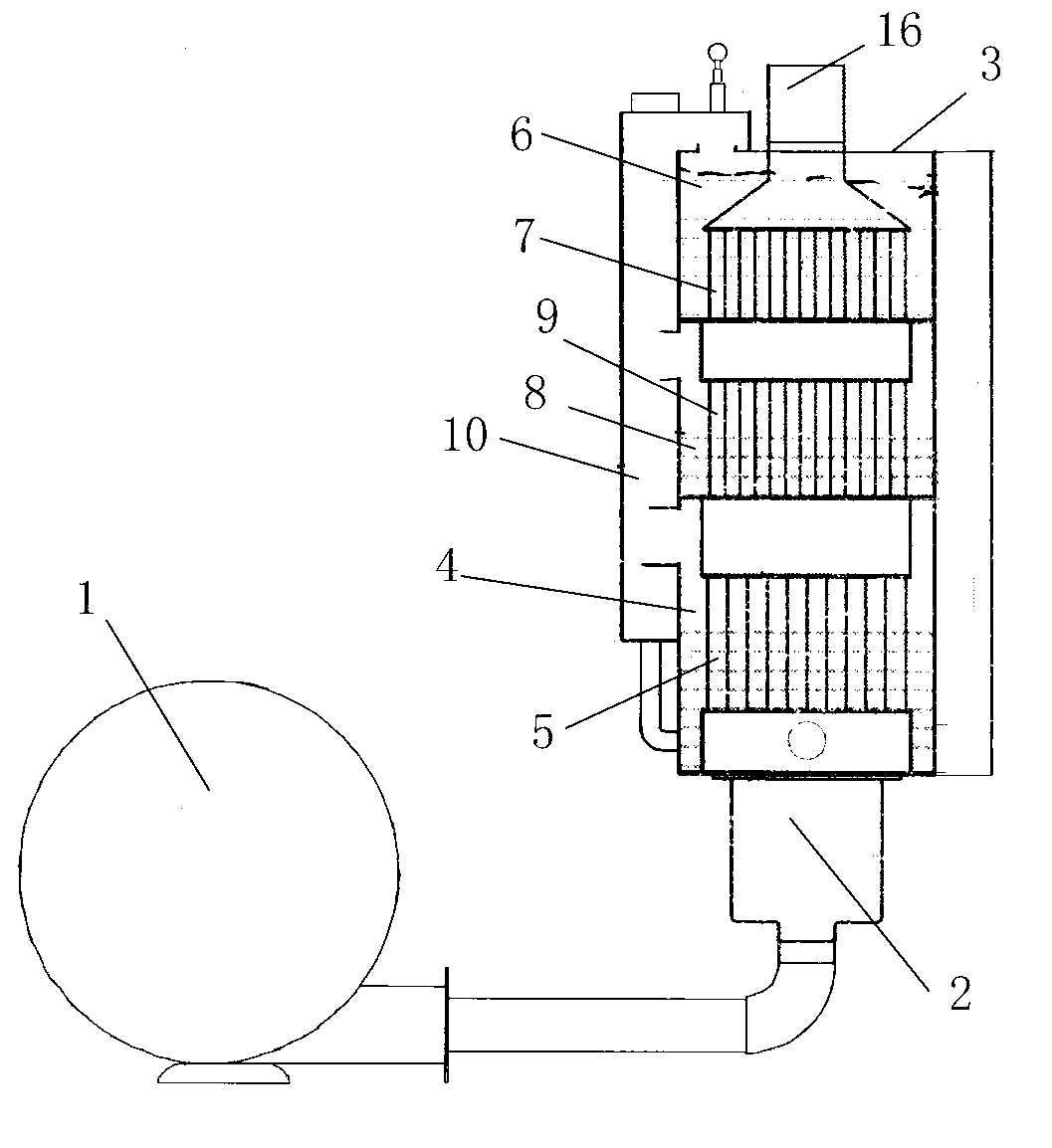

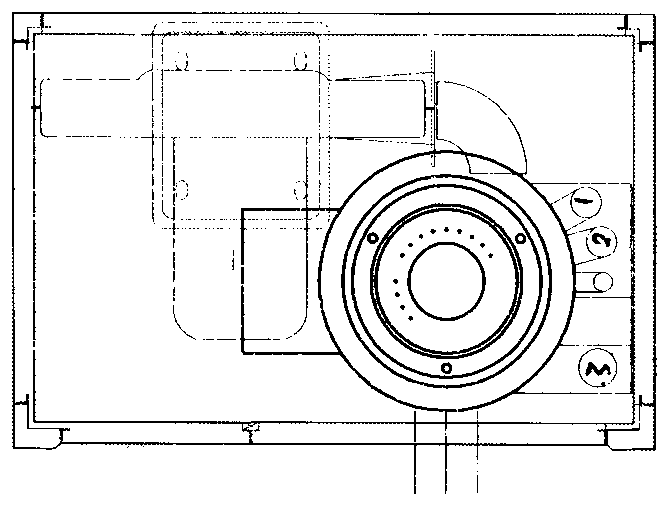

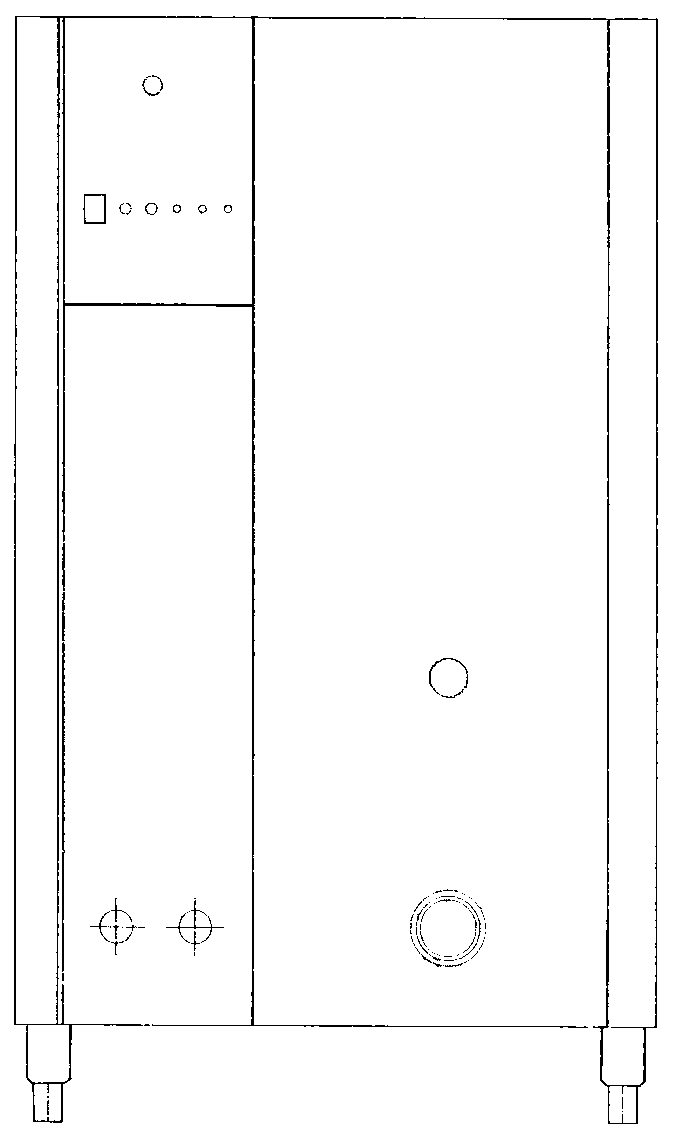

[0023] according to Figure 1 to Figure 4 As shown, the present invention includes a fan (1), a furnace head (2) whose bottom is connected to the air outlet of the fan (1), and is characterized in that a vertical combustion chamber (3) is fixed on the upper part of the fire outlet of the furnace head (2) , the vertical combustion chamber (3) is provided with at least three layers of combustion chambers from bottom to top, each layer of combustion chambers is equipped with vertical tubes, and the vertical combustion chamber (3) is equipped with a first-stage combustion chamber chamber (4), the first-stage combustion chamber (4) is set at the fire outlet of the burner (2), and the first-stage combustion chamber (4) is provided with a first-stage row pipe (5); the vertical combustion The topmost layer of the warehouse (3) is provided with an end-stage combustion chamber (6), and an end-stage exhaust pipe (7) is arranged in the end-stage combustion chamber (6); the first-stage com...

Embodiment 2

[0025] On the basis of Example 1, an ion flame detection device is installed inside the furnace head (2).

Embodiment 3

[0027] On the basis of Embodiment 1, the bottom of the plenum chamber communicates with the inside of the bottom side of the primary combustion chamber (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com