A method for improving the cleanliness of steel containing nb and ti

A cleanliness, tons of steel technology, applied in the field of reducing non-metallic inclusions in Nb, Ti-containing steel, can solve the problems of difficult removal of composite inclusions, high rating of D-type inclusions in hot-rolled plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

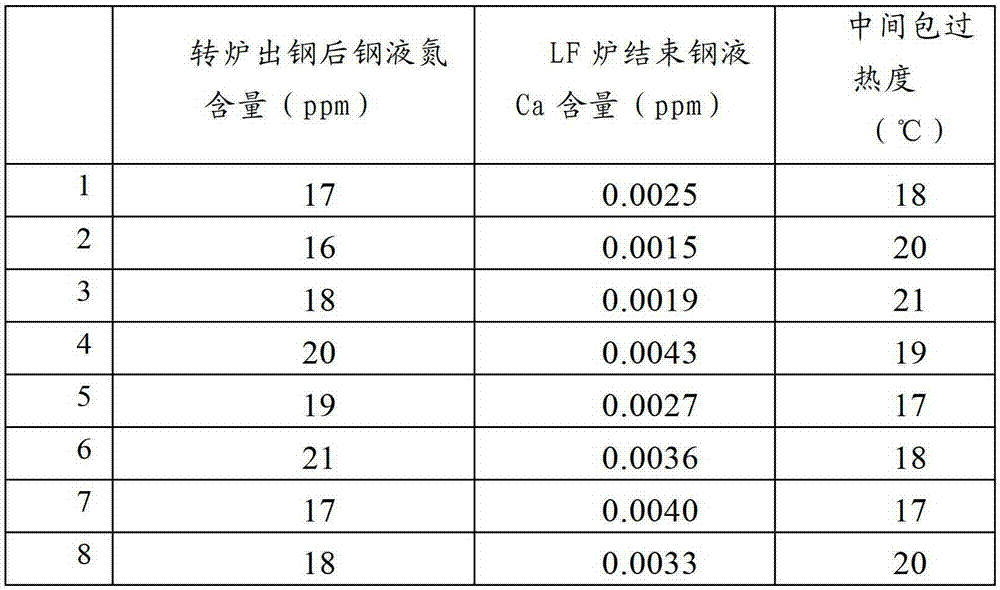

[0025] 8 heats of Nb and Ti hot-rolled steel grades are produced in a single casting time, and the process route of "converter-LF refining-RH refining-continuous casting" is used for production.

[0026] 300 tons of top-bottom combined blowing converter steelmaking, adding small grain lime 8kg / ton steel and fluorite 2kg / ton steel during the tapping process, adding slow-release deoxidizer 1kg / ton steel to the slag surface after tapping, and the liquid nitrogen content of the steel after tapping See Table 1. Calcium treatment is carried out after the LF furnace completes desulfurization and temperature rise. Each furnace is fed with 600m of Si-Ca wire, soft blowing, Nb-Ti alloying, and soft blowing. The process parameters are shown in Table 3. The Ca content at the end of LF furnace refining is shown in Table 1. The composition of the slag is shown in Table 2. Then carry out RH vacuum refining treatment, soft blowing after breaking the vacuum, soft blowing parameters are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com