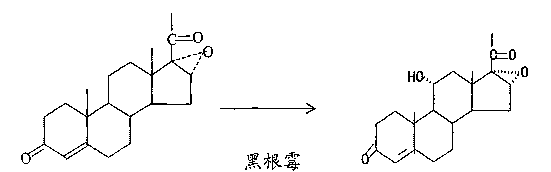

Process for synthesizing and preparing mildew oxide by mildew fermentation organisms and used novel nitrogen source

A technology of mold oxidation and fermentation organisms, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problem of unreasonable amino acid ratio and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of mold fermentation biosynthesis prepares the technique of mold oxide, it comprises the following steps:

[0030] 1. Mycelia preparation:

[0031] (1) Add 60kg of glucose, 40kg of corn steep liquor; new nitrogen source (the final concentration of each component of the new nitrogen source in the culture medium is: peptone: 5‰, yeast extract: 1‰, (NH 4 ) 2 SO 4 : 0.5‰, FeSO 4 ·7H 2 O: 0.01g‰, NaCl: 0.1‰, KH 2 PO 4 : 1‰, MgSO 4 ·7H 2 O: 0.2‰, Tween 80 1%); silkworm chrysalis powder 10kg; ammonium sulfate 5kg; polyether 1000mL was put into the primary fermentation tank at one time, 1.5 tons of water was added, the pH value was adjusted to 2, steam sterilized, and the temperature was lowered to 27 At ±3°C, insert 3 liters of spore suspension of Rhizopus niger, the concentration of spore suspension is 100,000 / mL, feed 0.21 times volume / min of air, stir and cultivate for 24 hours, and microscopically check, it is found that after the mycelia grow and mature, ...

Embodiment 2

[0037] A kind of mold fermentation biosynthesis prepares the technique of mold oxide, it comprises the following steps:

[0038] 1. Mycelia culture:

[0039] (1) Combine glucose 85kg, corn steep liquor 57kg; new nitrogen source (the final concentration of each component of the new nitrogen source in the culture medium is: peptone: 5‰, yeast extract: 1‰, (NH 4 ) 2 SO 4 : 0.5‰, FeSO 4 ·7H 2 O: 0.01g‰, NaCl: 0.1‰, KH 2 PO 4 : 1‰, MgSO 4 ·7H 2 O: 0.2‰, Tween 80 1%); silkworm chrysalis powder 20kg; ammonium sulfate 10kg; polyether 2000mL was put into the primary fermentation tank at one time, added 1 ton of water, adjusted the pH value to 3.5, steam sterilized, and cooled to 27 At ±3°C, insert 28 liters of the spore suspension of Rhizopus niger, the concentration of the spore suspension is 1.5 million / mL, feed 0.24 times the volume / min of air, stir and cultivate for 36 hours, and microscopically check, it is found that after the mycelium grows mature, Move into the secon...

Embodiment 3

[0045] A kind of mold fermentation biosynthesis prepares the technique of mold oxide, it comprises the following steps:

[0046] 1. Mycelia culture:

[0047] (1) Add 75kg of glucose, 50kg of corn steep liquor; new nitrogen source (the final concentration of each component of the new nitrogen source in the culture medium is: peptone: 5‰, yeast extract: 1‰, (NH 4 ) 2 SO 4 : 0.5‰, FeSO 4 ·7H 2 O: 0.01g‰, NaCl: 0.1‰, KH 2 PO 4 : 1‰, MgSO 4 ·7H 2 O: 0.2‰, Tween 80 1%); silkworm chrysalis powder 15kg; ammonium sulfate 8kg; polyether 1500mL was put into the primary fermentation tank at one time, added 1 ton of water, adjusted the pH value to 5, steam sterilized, and cooled to 27 At ±3°C, insert 50 liters of the spore suspension of Rhizopus niger purchased from the strain bank (purchased from the strain bank of China Institute of Pharmaceutical and Biological Products), the concentration of the spore suspension is 3 million / mL, and feed 0.28 times Volume / min air, stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com