Novel production process of pancreatin

A production process and technology of pancreatin, applied in pancreatin, drug combination, digestive system, etc., can solve the problems of low content of pancreatic amylase and pancreatic lipase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

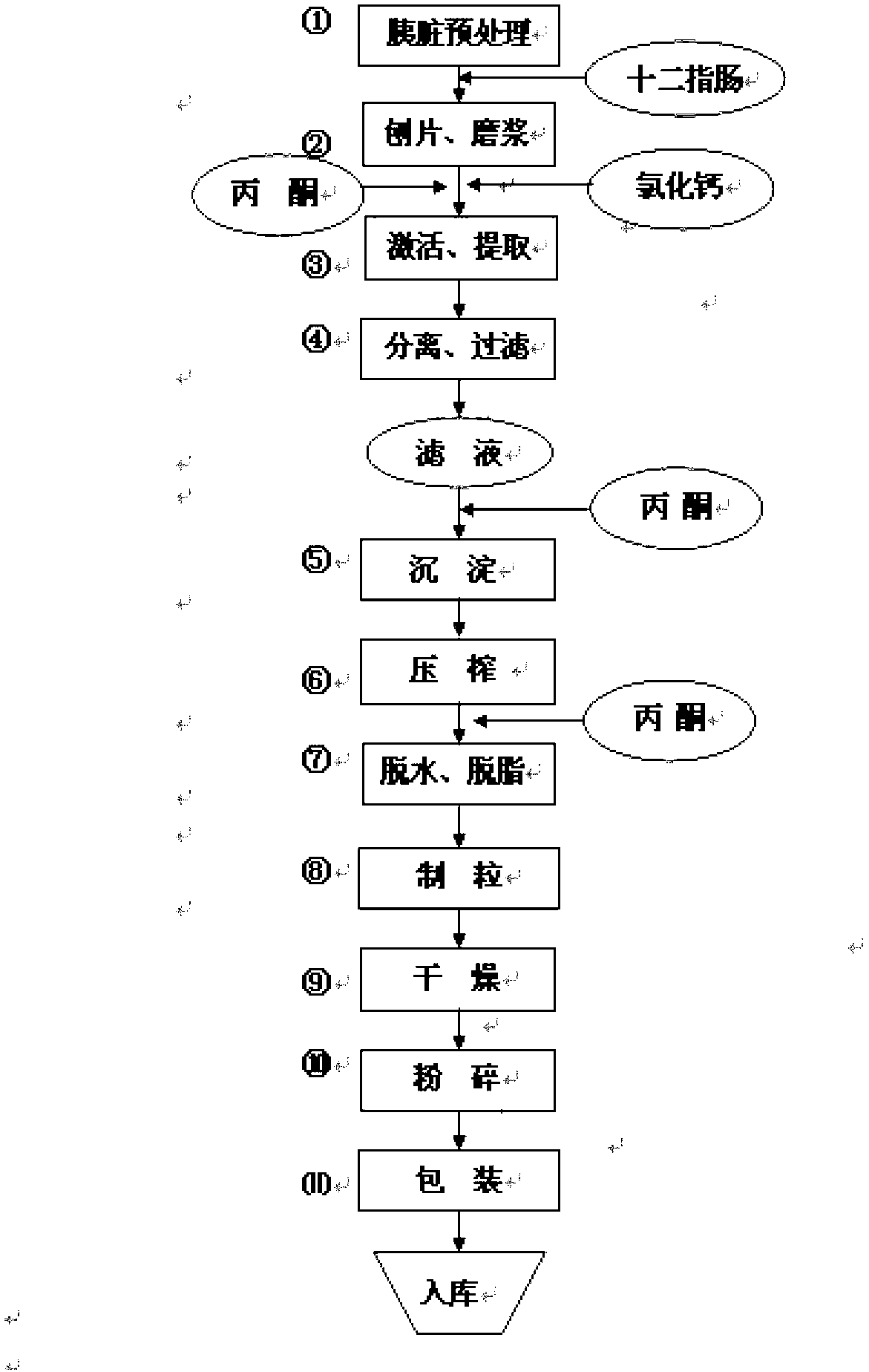

[0036] 1. Pancreatin production process

[0037] (1) The raw materials are porcine pancreas and porcine duodenum. Accurately weigh the raw materials that pass the quarantine, put them in the stainless steel tank in the pretreatment room, and let them thaw naturally for 10 hours;

[0038] (2) Flaking and refining: flaking the thawed raw materials with a pancreas planer, stirring and mixing the flaked raw materials with 1 times the amount (w / w) of low-concentration acetone solution; the low-concentration acetone is The acetone aqueous solution of 10% by volume is refined with a colloid mill;

[0039] (3) Activation and extraction: add 0.2% CaCl of raw material weight to the refining pulp 2 Activate as an activator, stir evenly, put into the extraction tank, temperature 5°C, extract for 20 hours;

[0040] (4) Separation and filtration: separate and filter the activated extract with a separator, and collect the pancreas milk filtrate;

[0041] (5) Precipitation: pump the pancre...

Embodiment 2

[0088] (1) The raw materials are porcine pancreas and porcine duodenum. Accurately weigh the raw materials that pass the quarantine, put them in the stainless steel tank in the pretreatment room, and let them thaw naturally for 5 hours;

[0089] (2) Planing and refining: planing the thawed raw materials with a pancreas planer, stirring and mixing the planed raw materials with 2 times the amount (w / w) of low-concentration acetone solution; the low-concentration acetone is The acetone aqueous solution of 30% by volume is refined with a colloidal mill;

[0090] (3) Activation and extraction: add 0.5% CaCl of raw material weight to the refining pulp 2 Activate as an activator, stir evenly, put into the extraction tank, temperature 10°C, extract for 15 hours;

[0091] (4) Separation and filtration: separate and filter the activated extract with a separator, and collect the pancreas milk filtrate;

[0092] (5) Precipitation: pump the pancreas milk filtrate into the sedimentation t...

Embodiment 3

[0107] (1) The raw materials are porcine pancreas and porcine duodenum. Accurately weigh the raw materials that pass the quarantine, put them in the stainless steel tank in the pretreatment room, and let them thaw naturally for 1 hour;

[0108] (2) Flaking and refining: flaking the thawed raw materials with a pancreas planer, stirring and mixing the flaked raw materials with 1.5 times (w / w) low-concentration acetone solution; the low-concentration acetone is The acetone aqueous solution of 20% by volume is refined with a colloid mill;

[0109] (3) Activation and extraction: add 0.4% CaCl of raw material weight to the refining pulp 2 Activate as an activator, stir evenly, put into the extraction tank, temperature 15°C, extract for 8 hours;

[0110] (4) Separation and filtration: separate and filter the activated extract with a separator, and collect the pancreas milk filtrate;

[0111] (5) Precipitation: pump the pancreas milk filtrate into the sedimentation tank, add acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com