Capacitive type operation electrode circuit pad

A surgical electrode and capacitive technology, applied in the direction of heating surgical instruments, etc., can solve problems such as increased capacitive reactance, affecting surgical effects, high-frequency current path impedance, etc., to achieve the effect of solving separation problems and ensuring work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

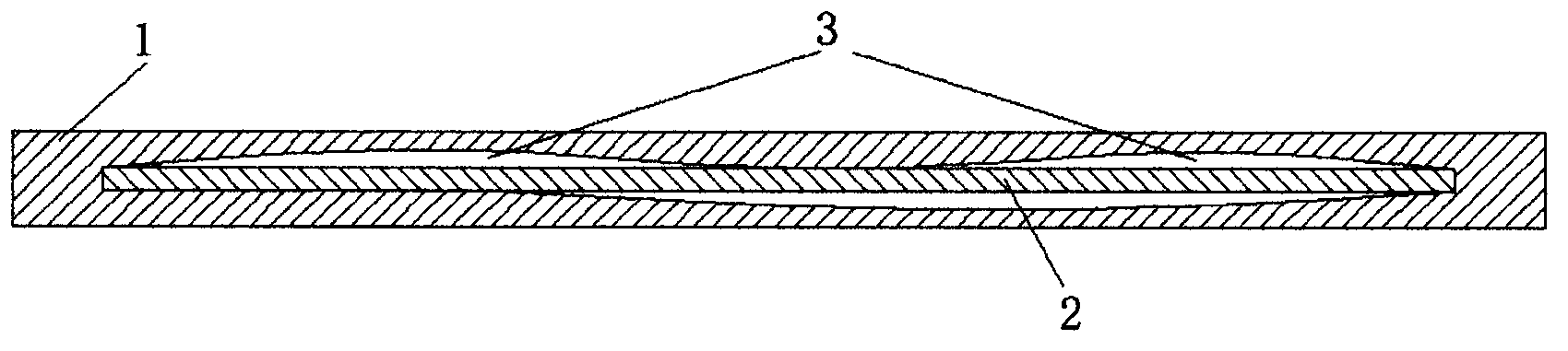

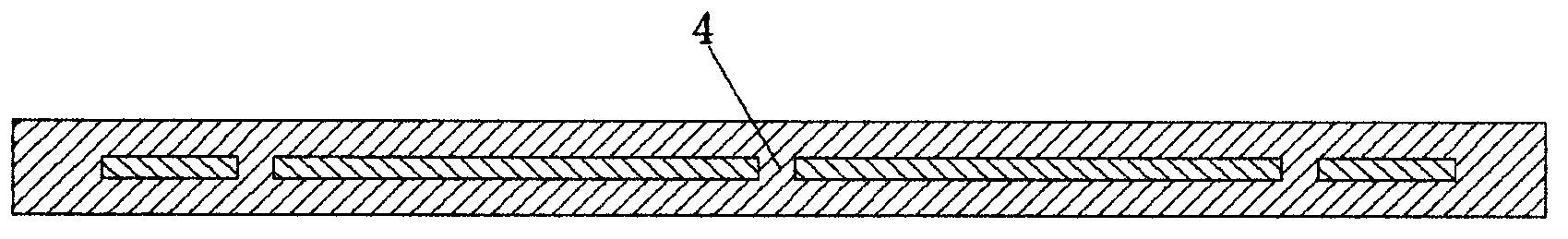

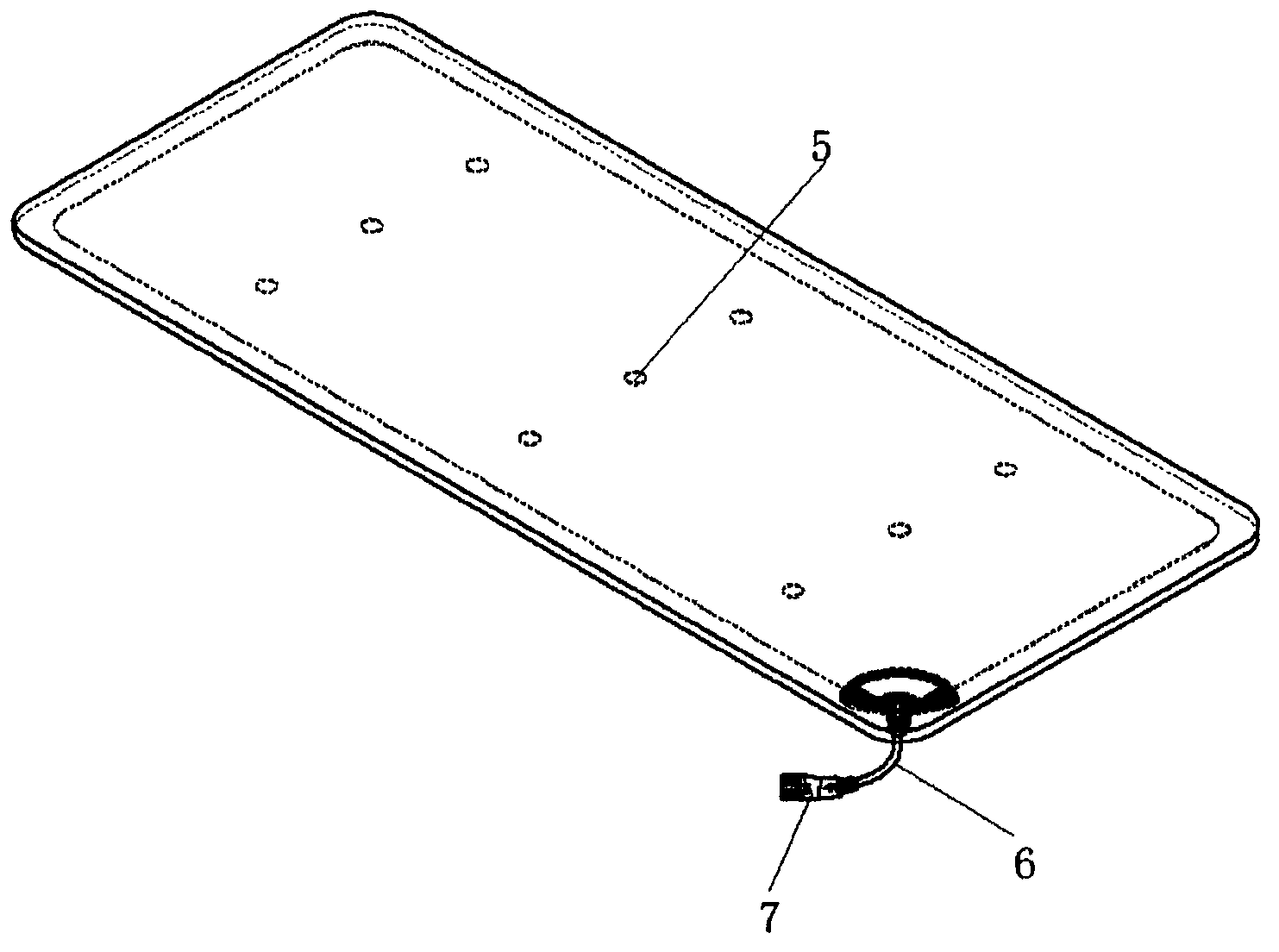

[0033] The invention relates to a capacitive surgical electrode circuit pad. In order to solve the change in capacitance caused by the separation of the capacitor plate and the insulating medium, the method of punching holes in the capacitor plate is adopted, so that the insulating medium can connect the two sides into one through the punching holes. Reliably ensure that the insulating medium and the capacitor plate are no longer separated. The specific implementation method is to pour polymer gel on one side of the capacitor plate, and then pour polymer gel on the other side of the capacitor plate when the required thickness is reached. Therefore, the polymer gel The gel is still in a viscous liquid state, so the two sides will be melted into one by punching the capacitor plate. According to actual needs, 4-5 rows of holes can be punched in the length direction of the capacitor plate. In this embodiment, 3 rows of holes are punched.

[0034] Another improved embodiment is to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com