Low-speed direct-drive hydraulic ocean current power generator and control method thereof

A technology of ocean current power generation and control methods, which is applied in transmission device control, electromechanical devices, fluid transmission devices, etc., can solve the problems of large size, difficult installation and maintenance, and high production cost of direct drive motors, and achieve low cost, reduced failure rate, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0036] 1. For the above-mentioned low-speed direct-drive hydraulic type ocean current power generation device:

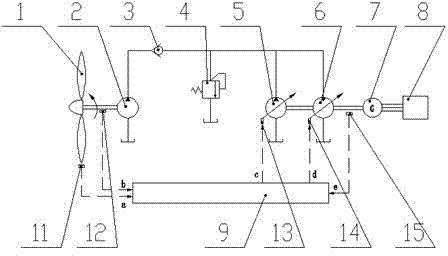

[0037] figure 1 The structure of the embodiment of the low-speed direct-drive hydraulic type ocean current power generation device of the present invention is shown, the main shaft of the impeller 1 is connected with the quantitative hydraulic pump 2, the inlet of the quantitative hydraulic pump 2 is connected to the fuel tank, and the outlet of the quantitative hydraulic pump 2 is connected in series with the quantitative hydraulic pump 2 The variable hydraulic pump 5 and the variable hydraulic motor 6, the outlets of the parallel variable hydraulic pump 5 and the variable hydraulic motor 6 are connected to the oil tank, the main shaft of the variable hydraulic pump 5 and the variable hydraulic motor 6 are rigidly connected, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com