Preparation method of hot-melt adhesive for multilayer oxygen-resistance pipe

A hot melt adhesive and oxygen barrier technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve problems such as unstable bonding, achieve fast bonding speed, simple preparation method, and high performance low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

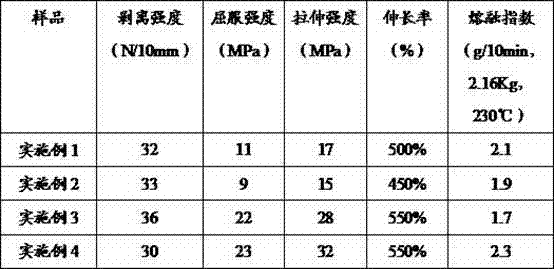

Examples

Embodiment 1

[0029] 10Kg of random copolymer polypropylene with MI of 0.6 g / 10min (2.16Kg, 230°C), 200g maleic anhydride, 30g dicumyl peroxide and 20g antioxidant 1010 in a high-speed mixer at 200rpm After mixing for 30 minutes, 150g of mineral oil or acetone can be added, so that a small amount of initiator can be adsorbed on the surface of HDPE particles to achieve their uniform mixing. The above-mentioned uniformly mixed materials are melted and mixed in a twin-screw extruder at an extrusion temperature of 200° C., unreacted monomers are removed under a vacuum of 0.1 MPa, and after cooling and pelletizing, a polypropylene graft is obtained.

[0030] The above-mentioned 4Kg polypropylene graft, 2Kg tackifying resin EPDM, 2Kg tackifying resin POE, 1Kg polyethylene elastomer versify de2300, and 1Kg styrene elastomer SEBS are thoroughly mixed uniformly through a high-mixer. The uniformly mixed materials are extruded and pelletized on a twin-screw extruder at an extrusion temperature of 190°C t...

Embodiment 2

[0032] The MI of 10Kg is 4.0 g / 10min (2.16Kg, 230℃) homopolymerized polypropylene, 150g maleic anhydride, 20g acrylic acid, 10g 2,5-dimethyl-2,5-bis(tert-butyl peroxide) ) Hexane and 20g antioxidant 215 are mixed in a high-speed mixer at 300 rpm for 10 minutes, 150g of mineral oil or acetone can be added, so that a small amount of initiator can be adsorbed on the surface of LLDPE particles to achieve their uniform mixing. The above-mentioned uniformly mixed materials are melted and mixed in a twin-screw extruder at an extrusion temperature of 190° C., unreacted monomers are removed under a vacuum of 0.1 MPa, and after cooling and pelletizing, a polypropylene graft is obtained.

[0033] The above-mentioned 3.5Kg polypropylene graft, 3.5Kg tackifying resin POE, 2Kg polyethylene elastomer versify de2300, and 1Kg styrene elastomer SIS are thoroughly mixed uniformly through a high mixer. The uniformly mixed materials are extruded and pelletized on a twin-screw extruder at an extrusion...

Embodiment 3

[0035] The 10Kg MI is 5.0 g / 10min (2.16Kg, 230℃) syndiotactic copolymer polypropylene, 150g maleic anhydride, 20g bis(tert-butylperoxyisopropyl)benzene and 10g antioxidant 215 at high speed The mixer is mixed at 250 rpm for 15 minutes, and 150 g of mineral oil or acetone can be added, so that a small amount of initiator can be adsorbed on the surface of the LLDPE particles to achieve their uniform mixing. The above-mentioned uniformly mixed materials are melted and mixed in a twin-screw extruder at an extrusion temperature of 190°C. The unreacted monomers are removed under a vacuum of 0.1 MPa, and after cooling and pelletizing, the grafted LLDPE is obtained.

[0036] The above 2Kg polypropylene grafted product, 4Kg MI of 0.7 g / 10min (2.16Kg, 230℃) copolymerized polypropylene, 1Kg tackifying resin POE, 1Kg polyethylene elastomer versify de 2300, fully mixed by a high mixer Evenly. Extrude and granulate the uniformly mixed materials on a twin-screw extruder at an extrusion tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com