Oxidation method of acetophenone

A technology of acetophenone and oxidant, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve problems such as complex production process and harmful emissions, and achieve the effect of overcoming complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

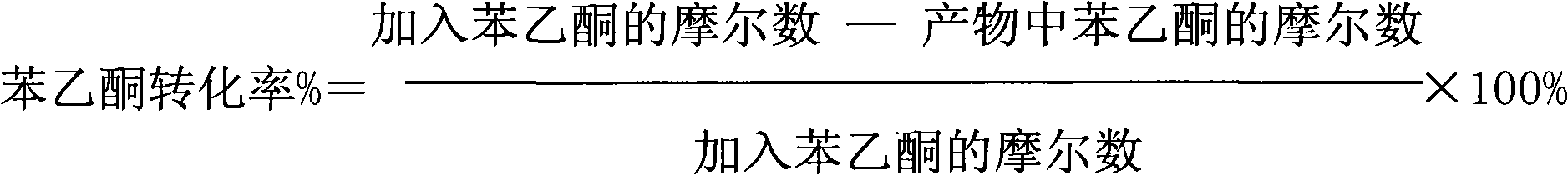

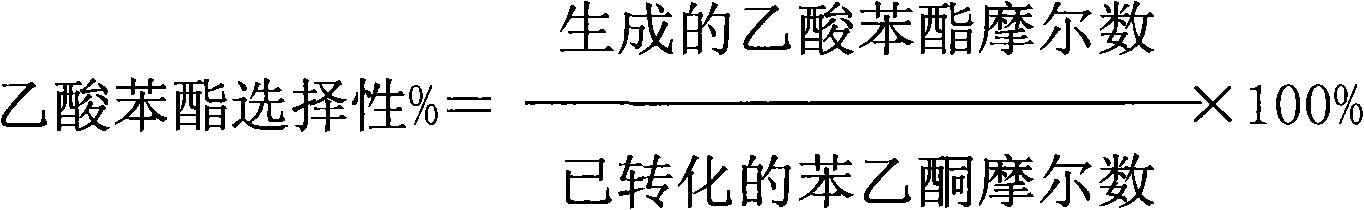

Embodiment 1

[0033] With acetophenone, hydrogen peroxide, solvent and catalyst (the mol ratio of zinc nitrate and titanium silicon molecular sieve 0.2: 1) according to acetophenone and hydrogen peroxide mol ratio is 1: 10, solvent acetonitrile and catalyst mass ratio are 20: 1. The mass ratio of acetophenone to catalyst is 10:1, and the reaction is carried out at a temperature of 50° C. and a pressure of 1.5 MPa. After 2 hours of reaction, the conversion rate of acetophenone was 83%; the selectivity of phenyl acetate was 66%.

Embodiment 2

[0035] Acetophenone, hydrogen peroxide, solvent and catalyst (the molar ratio of zinc phosphate and titanium silicon molecular sieve 1: 1) is 1: 6 according to the molar ratio of acetophenone and hydrogen peroxide, and the mass ratio of solvent acetone and catalyst is 50: 1. The mass ratio of acetophenone to catalyst is 20:1, and the reaction is carried out at a temperature of 60° C. and a pressure of 2.5 MPa. After 2 hours of reaction, the conversion rate of acetophenone was 59%; the selectivity of phenyl acetate was 68%.

Embodiment 3

[0037]With acetophenone, hydrogen peroxide, solvent and catalyst (the mol ratio of zinc sulfate and titanium silicon molecular sieve 0.1: 1) according to acetophenone and hydrogen peroxide mol ratio is 2: 11, solvent acetic acid and catalyst mass ratio are 60: 1. The mass ratio of acetophenone to catalyst is 1:1, and the reaction is carried out at a temperature of 100° C. and a pressure of 0.5 MPa. After 2 hours of reaction, the conversion rate of acetophenone was 56%; the selectivity of phenyl acetate was 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com