Method for pretreatment of propylene oxide wastewater by using micro-electrolysis

A propylene oxide, pretreatment technology, applied in natural water treatment, water/sewage treatment, chemical instruments and methods, etc. problems, to ensure long-term stable operation, good social and environmental benefits, and reduce cleaning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

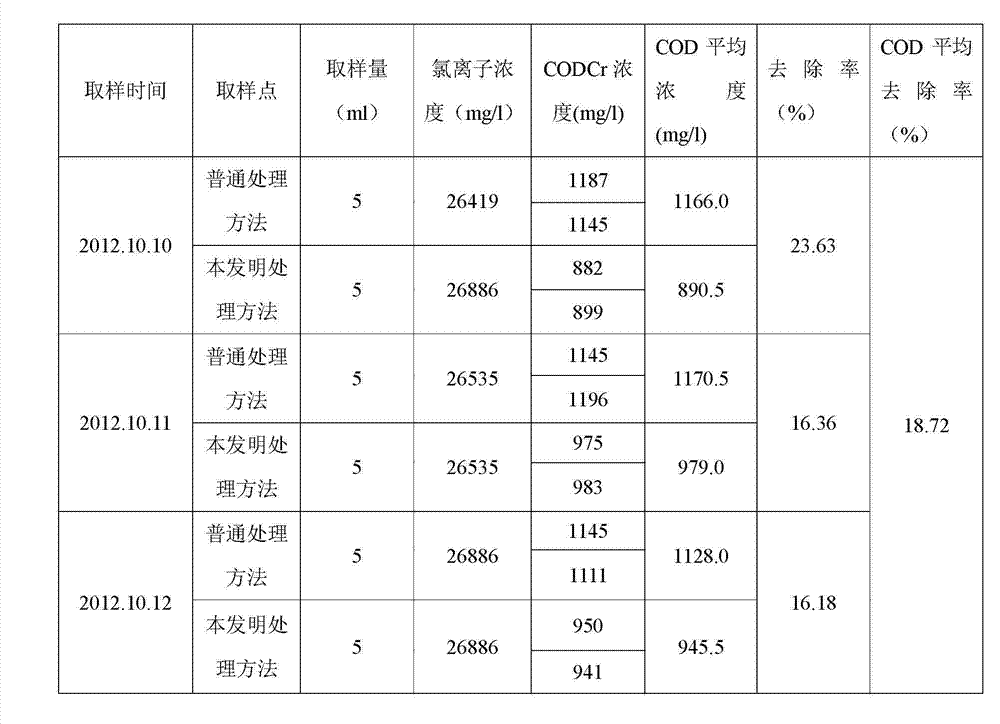

[0015] 1. Project name: Binhua Propylene Oxide Wastewater Emergency Treatment Project.

[0016] 2. Processing scale: 12000m 3 / d.

[0017] 3. Wastewater before treatment: mainly containing organic compounds such as chloropropanol, with an average COD of 1135mg / l, B / C value less than 0.3, Cl - 20000~24000mg / l, PH≥12.

[0018] 4. Wastewater treatment process:

[0019] The wastewater first passes through the cooling tower to cool the water temperature below 40°C, and then enters the aluminum-silicon micro-electrolysis device for low-pressure catalytic electrolysis treatment for 10 minutes. -The silicon micro-electrolysis device is fed with compressed air for aeration, and the wastewater treated by the aluminum-silicon micro-electrolysis device enters the sedimentation tank for sedimentation, and the settled wastewater enters the biochemical tank for biological treatment.

[0020] The aluminum-silicon micro-electrolysis device described herein is designed in parallel with thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com