Method for producing nano chromium nitride powder

A nano-nitridation and powder technology, applied in the direction of nanotechnology, nanotechnology, nitrogen-metal/silicon/boron binary compounds, etc., can solve the problems of increasing difficulty and dangerous yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

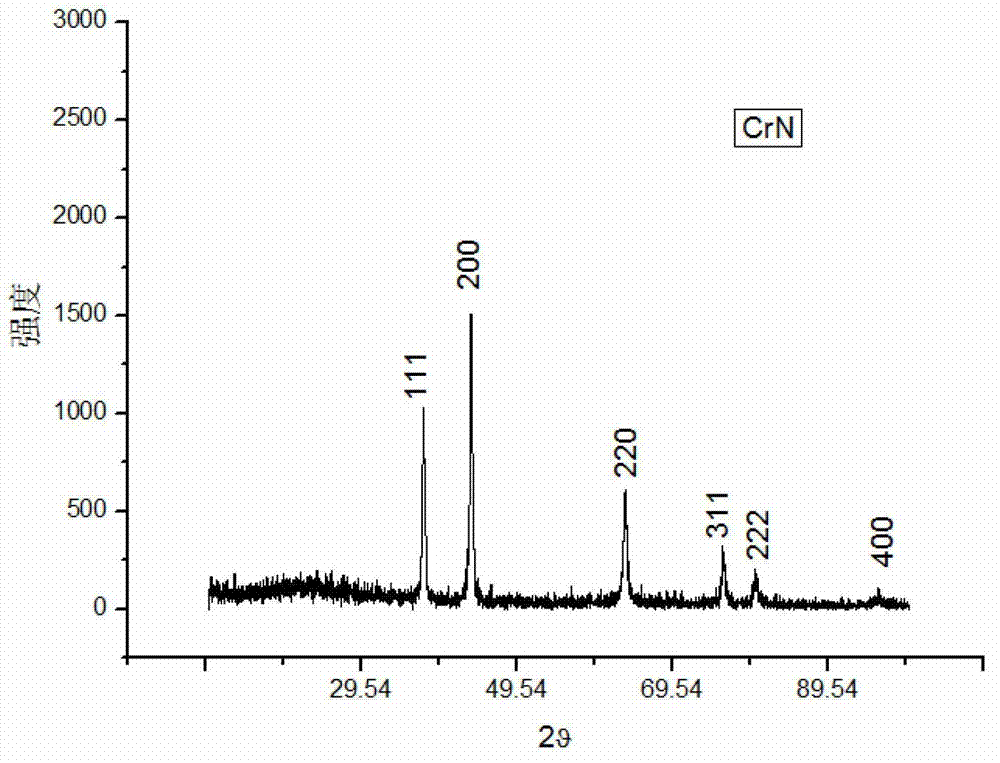

Image

Examples

Embodiment 1

[0019] Weigh 0.05 mol of chromium nitrate and 0.05 mol of glycine and dissolve them in 150 ml of distilled water to prepare a solution, and heat the solution on a temperature-controllable electric furnace at 300°C. After the solution undergoes a series of processes such as volatilization, concentration, and bubbling, the precursor powder is obtained. After the precursor powder is pulverized, it is reacted in the furnace at 800 °C and the flow rate of ammonia gas is 0.25 L / min for 6 hours to obtain Nano chromium nitride powder.

Embodiment 2

[0021] Weigh 0.05 moles of chromium nitrate, 0.05 moles of glycine, and 0.075 moles of glucose and dissolve them in 150 ml of distilled water to prepare a solution, and heat the solution on a temperature-controllable electric furnace at 300°C. After the solution undergoes a series of processes such as volatilization, concentration, and bubbling, the precursor powder is obtained. After the precursor powder is pulverized, it is treated in the air at 700°C for 90 minutes. / min under the condition of reaction in the furnace for 6 hours to obtain nano-chromium nitride powder.

Embodiment 3

[0023] Weigh 0.05 moles of chromium nitrate, 0.05 moles of glycine, and 0.05 moles of glucose and dissolve them in 150 ml of distilled water to prepare a solution, and heat the solution on a temperature-controllable electric furnace at 300°C. After the solution undergoes a series of processes such as volatilization, concentration, and bubbling, the precursor powder is obtained. After the precursor powder is pulverized, it is treated in the air at 700°C for 60 minutes. / min conditions in the furnace for 4 hours to obtain nano-chromium nitride powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com