Method for preparing polyvinylidene fluoride film

A technology of polyvinylidene fluoride and polyvinylidene fluoride resin, which is applied in the preparation and application of new polymer functional materials, can solve problems such as increased process difficulty, low biaxial tensile strength, and impact on film performance, and achieves Satisfy the effect of industrialized mass production, improve the bidirectional tensile strength, and less process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

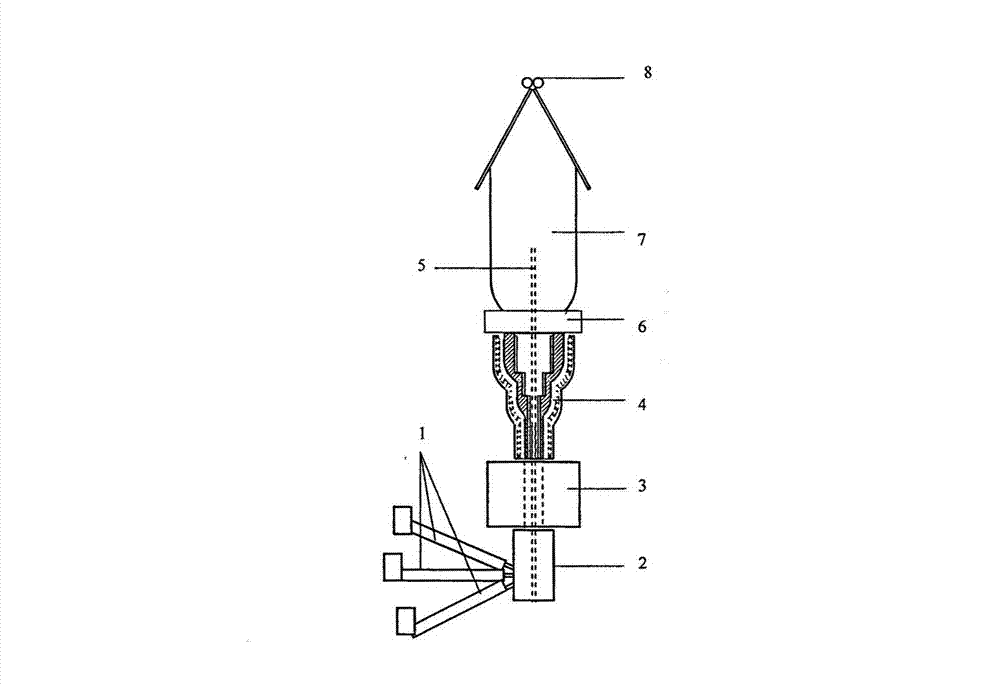

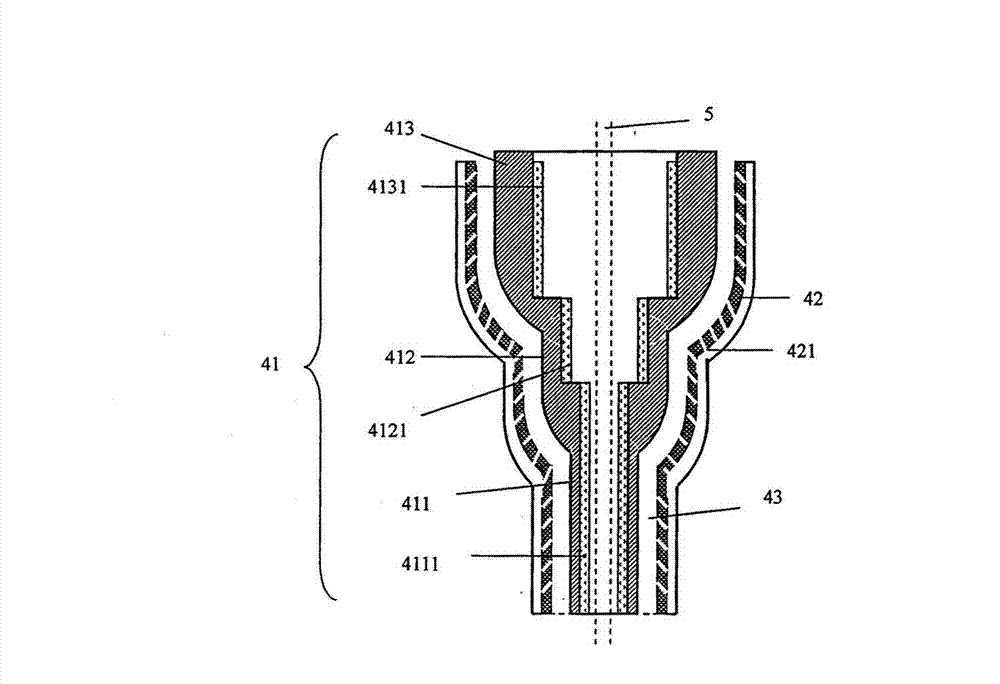

[0032] please see figure 1 and figure 2 , taking the preparation of a polyvinylidene fluoride film with a thickness of 50 μm as an example, the steps involved are as follows:

[0033] A) Ingredients, select the raw materials of the first blending component, the second blending component and the third blending component, wherein: the raw materials of the first blending component consist of the following raw materials in parts by weight Composition: 90 parts of homopolymerized polyvinylidene fluoride resin, 10 parts of polymethyl methacrylate resin, 0.5 part of dimethyl phthalate, 0.5 part of dibutyl phthalate and dihexyl phthalate 0.5 parts of ester; the raw materials of the second blending component are composed of the following raw materials in parts by weight: 20 parts of polyvinylidene fluoride resin copolymerized, 80 parts of polymethyl methacrylate resin, flow modified The agent is 2 parts of triethyl phosphate and the filler is 3 parts of calcium carbonate and 7 parts...

Embodiment 2

[0044] Take the preparation of a polyvinylidene fluoride film with a thickness of 150 μm as an example.

[0045] Change the raw material and components of the first blending component in step A) to 70 parts of polyvinylidene fluoride resin, 30 parts of polymethyl methacrylate resin and 3 parts of tributyl phosphate, and The raw material of the second blending component and its components are changed to 60 parts of homopolymerized polyvinylidene fluoride resin, 40 parts of polymethyl methacrylate resin, 1 part of dimethyl phthalate, phthalic acid 2 parts of dibutyl ester and 20 parts of titanium dioxide as a filler, change the raw material components of the third blending component into 60 parts of copolymerized polyvinylidene fluoride resin, 30 parts of polymethyl methacrylate resin and phthalic acid 1 part of dimethyl ester; change the temperature of the first zone of the twin-screw extruder in step C) to 150°C, change the temperature of the second to fifth zones to 220°C, an...

Embodiment 3

[0047] Take the preparation of a polyvinylidene fluoride film with a thickness of 10 μm as an example.

[0048] Change the raw materials of the first blending component in step A) to 80 parts of homopolymerized polyvinylidene fluoride resin, 30 parts of polymethyl methacrylate resin and 0.5 part of flow modifier tributyl phosphate, Change the raw material of the second blending component into 40 parts of copolymerized polyvinylidene fluoride resin, polymethyl methacrylate resin into 60 parts and 1 part of dibutyl phthalate, and change the third blending group 70 parts of homopolymerized polyvinylidene fluoride resin, 20 parts of polymethyl methacrylate resin, and 1 part of hexyl phthalate and 1 part of phthalate as the flow modifier. 4 parts of dioctyl formate; change the temperature of the first zone of the twin-screw extruder in step C) to 180°C, change the temperature of the second to fifth zones to 185°C, and put the material in the twin-screw extruder Change the time to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com