Analogue means of optical surface contamination and cleaning under extreme ultraviolet irradiation

An optical surface and simulation device technology, applied in the field of lithography, can solve the problems of only one vacuum pumping system, the sample stage does not have degrees of freedom, and the optical surface contamination and cleaning experimental functions cannot be realized at the same time, so as to prolong the life, Easy-to-place effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

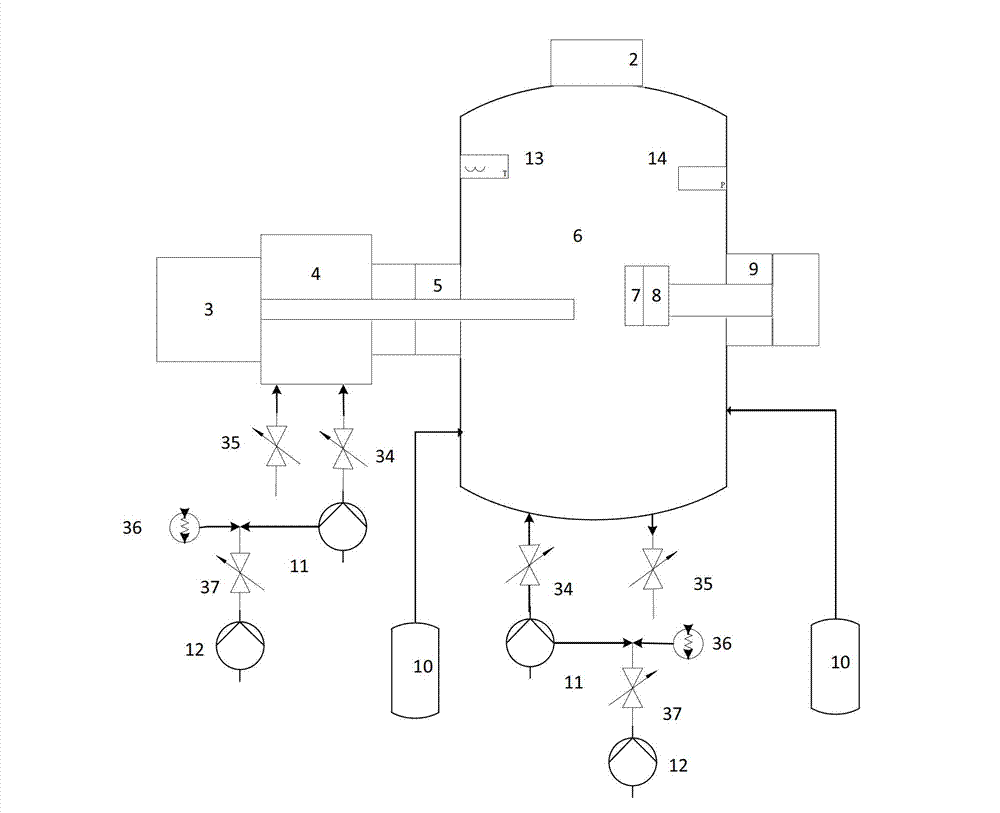

[0061] figure 1 Shown is a schematic structural view of the first embodiment of the present invention. Under this implementation mode, the present invention can realize the functions of optical surface contamination experiment and oxygen atom cleaning experiment under extreme ultraviolet light irradiation.

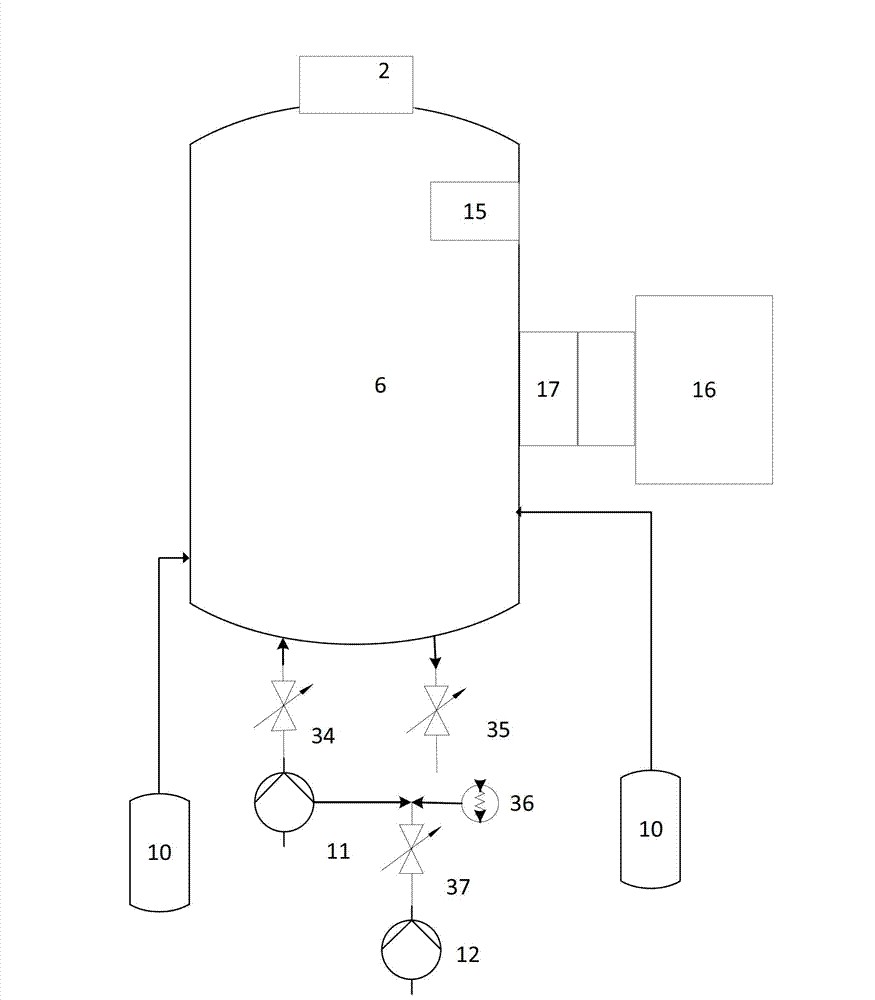

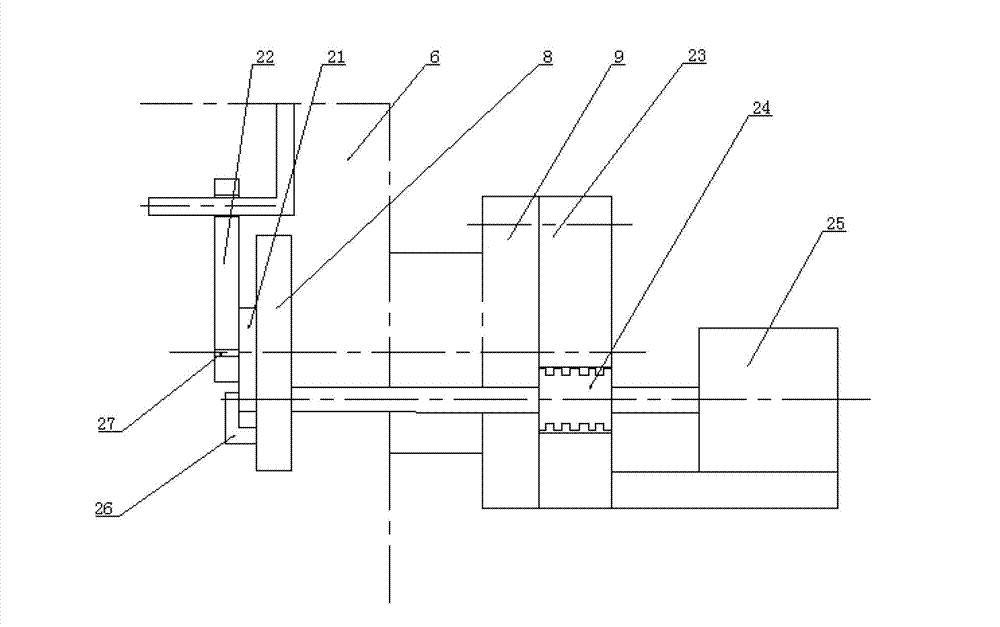

[0062] like figure 1 and figure 2 As shown, the optical surface pollution and cleaning simulation device under extreme ultraviolet light irradiation of the present invention includes: a hydrogen atom generator interface 2, an electron gun 3, an electron gun chamber 4, an electron gun interface 5, an exposure chamber 6, a cooling capillary 7, and a sample stage 8 , sample table interface 9, gas introduction equipment 10, temperature sensor 13, pressure sensor 14, vacuum gauge 15, residual gas analyzer (Remaining gas analyzer, RGA for short) 16, RGA interface 17 and two sets of secondary molecular pumps.

[0063] The exposure chamber 6 is the main chamber, and the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com