Urethane acrylate low polymer and preparation method and application thereof

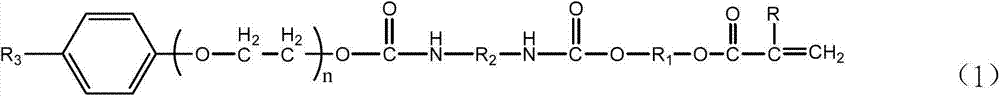

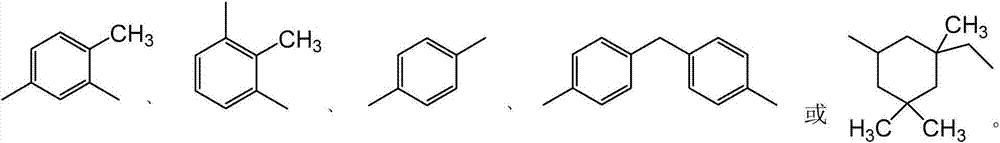

A technology of urethane acrylate and hydroxyalkyl acrylate is applied in the field of alkylphenol polyoxyethylene ether type urethane acrylate oligomer and its preparation, and can solve the irritating odor, high toxicity and poor film-forming performance of active monomers , increase film brittleness and other issues, to achieve the effect of improving adhesion and film-forming properties, high adhesion and film-forming properties, and reducing viscosity and functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Synthesis of the semi-adduct of alkylphenol polyoxyethylene ether and diisocyanate:

[0052] 39.8g of nonylphenol polyoxyethylene ether (n=4, Mn=396) was added to the reaction vessel, the temperature was raised to 60°C under stirring, 22.2g of isophorone diisocyanate was added dropwise, and the addition was completed within 0.5 hours. Post-insulation reaction for 30 minutes;

[0053] (2) Synthesis of urethane acrylate oligomer:

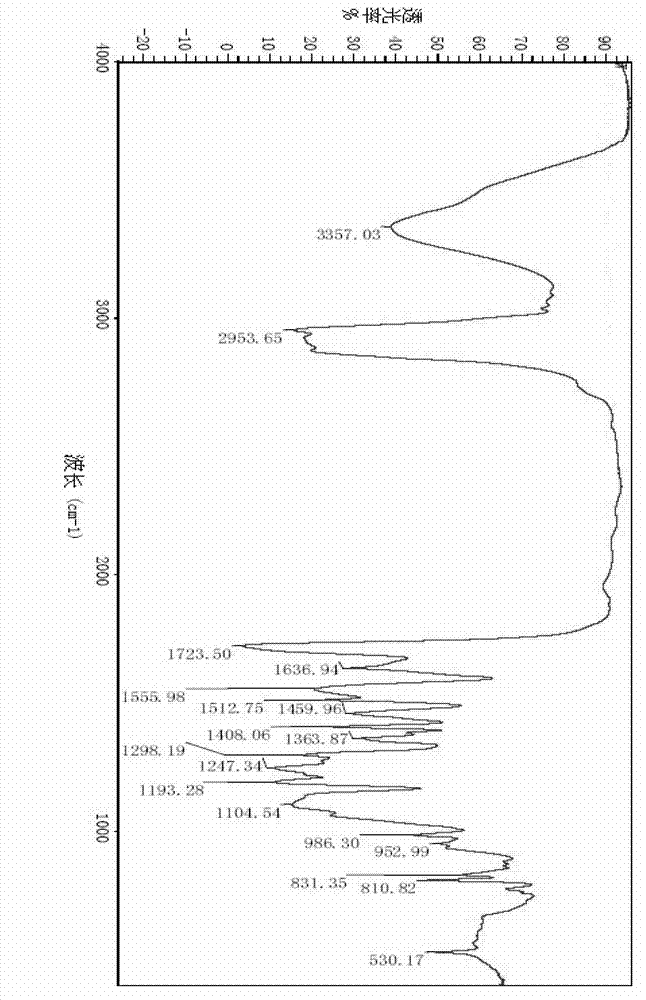

[0054] The system was cooled to 35°C, a homogeneous mixture of 13.0g of hydroxypropyl acrylate and 0.13g of hydroquinone was added dropwise, the addition was completed within 0.5 hours, and the reaction was kept for 30 minutes, and 0.06g of dibutyltin dilaurate was added dropwise. The reaction was continued for 60 minutes, then the temperature was raised to 60° C., and the reaction was continued for half an hour to obtain a nonylphenol polyoxyethylene ether type urethane acrylate oligomer I-1. The oligomer I-1 was tested by IR, and the sp...

Embodiment 2

[0057] (1) Synthesis of the semi-adduct of alkylphenol polyoxyethylene ether and diisocyanate:

[0058] 40.0g of nonylphenol polyoxyethylene ether (n=4, Mn=396) was added to the reaction vessel, the temperature was raised to 50°C under stirring, 25.0g of 4,4'4-diphenylmethane diisocyanate was added dropwise, and the temperature was controlled for 0.5 hours. The inner dropwise addition was completed, and the post-insulation reaction was performed for 15 minutes;

[0059] (2) Synthesis of urethane acrylate oligomer:

[0060] The system was cooled to 35°C, a homogeneous mixture of 13.0g hydroxyethyl methacrylate and 0.013g p-hydroxyanisole was added dropwise, the dropwise addition was completed within 0.5 hours, and the reaction was incubated for 20 minutes, and 0.04g dilauric acid was added dropwise. Dibutyltin, and continue to react for 45 minutes, then the temperature is raised to 50° C., and the reaction is continued for half an hour to obtain nonylphenol polyoxyethylene eth...

Embodiment 3

[0063] (1) Synthesis of the semi-adduct of alkylphenol polyoxyethylene ether and diisocyanate:

[0064] 39.6g of nonylphenol polyoxyethylene ether (n=4, Mn=396) was added to the reaction vessel, the temperature was raised to 40° C. under stirring, 17.4g of toluene diisocyanate was added dropwise, and the addition was completed within 0.5 hours, and the reaction was kept warm. 5 minutes;

[0065] (2) Synthesis of urethane acrylate oligomer:

[0066] The system was cooled to 35°C, a uniform mixture of 11.6g hydroxyethyl acrylate and 0.006g p-hydroxyanisole was added dropwise, the dropwise addition was completed within 0.5 hours, and the reaction was maintained for 15 minutes, and 0.04g dibutyltin dilaurate was added dropwise. , and continued to react for 40 minutes, then the temperature was raised to 50° C., and the reaction was continued for half an hour to obtain nonylphenol polyoxyethylene ether type urethane acrylate oligomer I-3.

[0067] The oligomer viscosity was determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com