Method and device utilizing low-grade waste heat

A low-grade, waste heat technology, used in machines that use waste heat, machine operation, energy-saving heating/cooling, etc. It can solve the problems of poor heat exchanger economy, waste of cooling capacity, and large heat exchange area, and achieve effective utilization. , The requirements for material and process control are reduced, and the economy is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

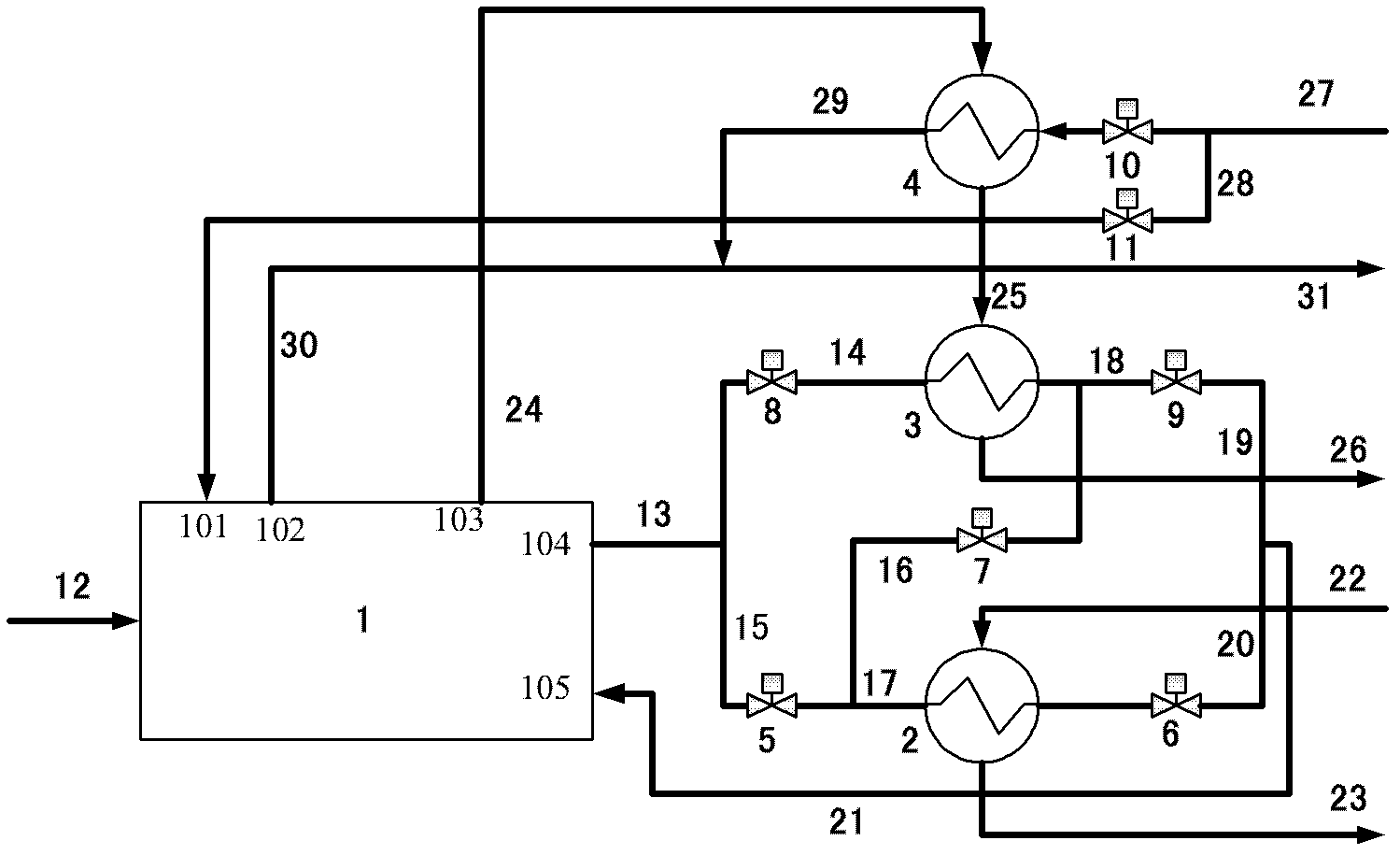

[0053] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

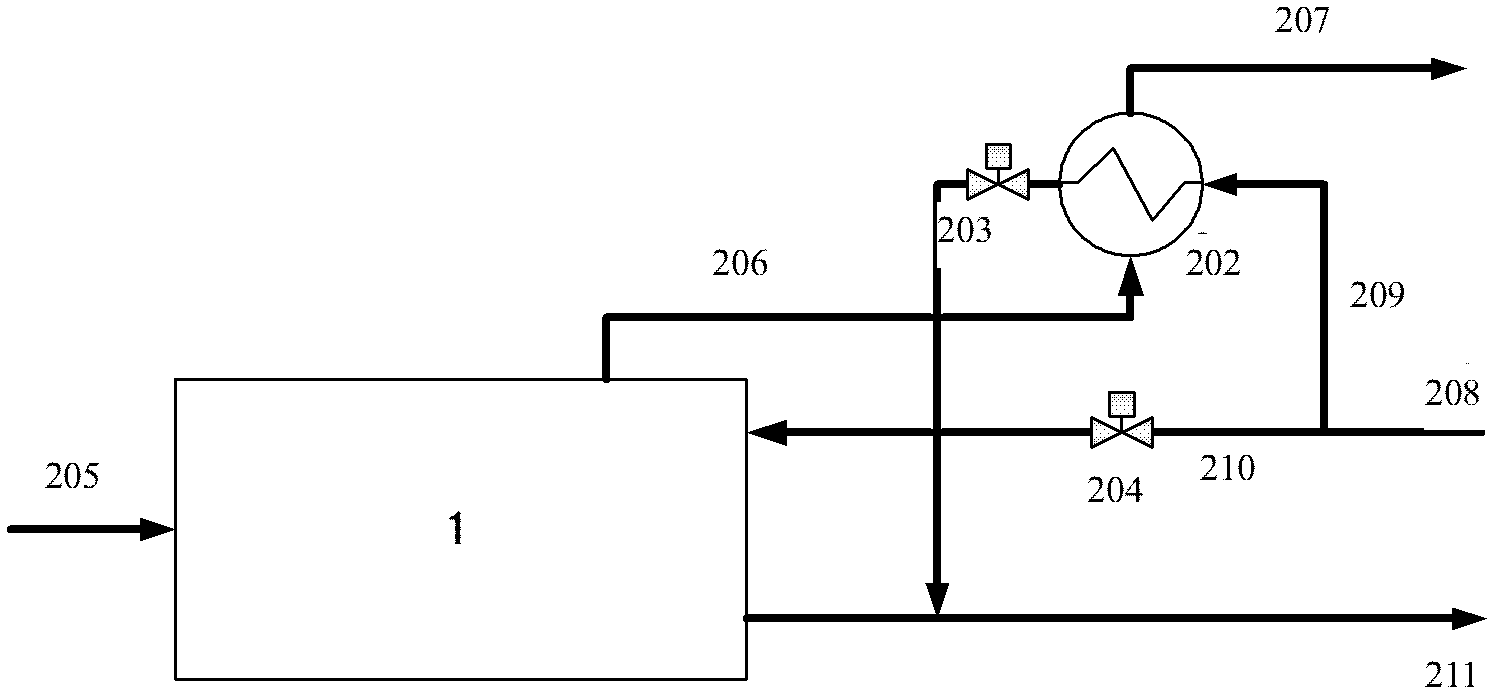

[0054] see figure 2 Describe the method for utilizing low-grade waste heat of the present invention, which includes: introducing the flue gas discharged from the absorption direct combustion engine 1 into the flue gas heat exchanger 4 and recovering the sensible heat of the flue gas; The flue gas is introduced into the flue gas condensing heat exchanger 3 and the latent heat recovery is performed on the flue gas after recovering the sensible heat; the flue gas after the latent heat is recovered is discharged, wherein the absorption direct combustion engine 1 is In the heating season, it operates in the cooling season mode, the recovered sensible heat is replaced by the hot water discharged from the circulating heating water outlet of the absorption direct combustion engine 1, and the recovered latent heat is replaced by the absorption direct combustion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com