Hydrocracking method for producing gasoline blending component with high octane value

A technology for high-octane gasoline and blending components, which is applied in chemical instruments and methods, hydrocarbon oil cracking, hydrotreating processes, etc., and can solve the problem of low octane gasoline products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

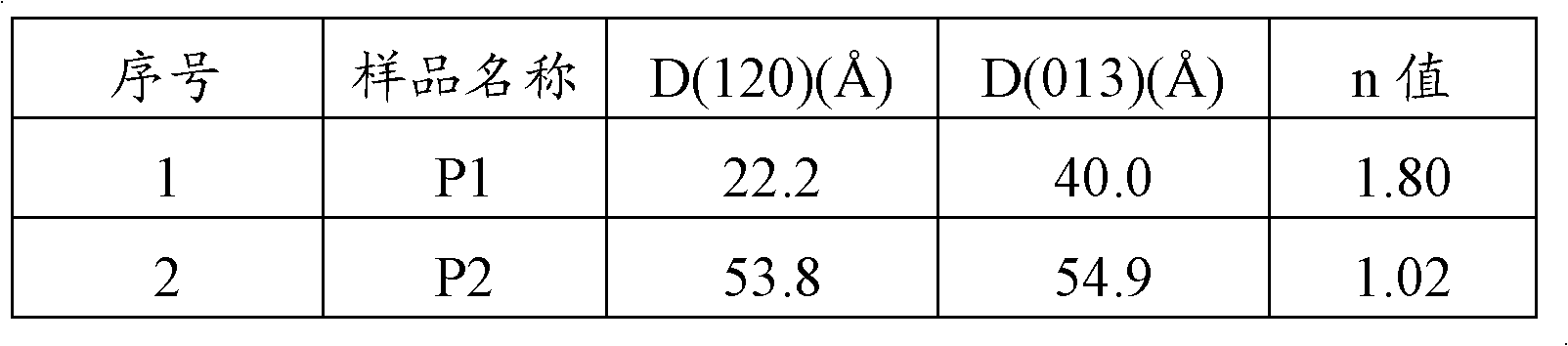

Image

Examples

Embodiment 1

[0076] The raw material oil D enters the hydrogenation reactor together with hydrogen, and successively contacts and reacts with the hydrofinishing catalyst A in the first reaction zone and the hydrocracking catalyst C in the second reaction zone. The effluent after the reaction enters the high-pressure reactor without any intermediate separation. Separator, low-pressure separator, after cooling and separation, the hydrogen-rich gas is recycled, and the liquid product enters the fractionation system to be separated into gasoline fraction and diesel fraction. The nitride content in the product is 1.7μg / g, and the denitrification rate is as high as 99.5%. Control the saturation depth of aromatics in the first reaction zone, that is, compared with diesel feedstock oil, the saturation rate of aromatics with double rings or more in the reaction effluent of the first reaction zone is 62.7%, and the reaction effluent in the first reaction zone Based on the liquid component, the conte...

Embodiment 2

[0079] The raw material oil E enters the hydrogenation reactor together with hydrogen, and successively contacts and reacts with the hydrofinishing catalyst A in the first reaction zone and the hydrocracking catalyst C in the second reaction zone. The effluent after the reaction enters the high-pressure reactor without any intermediate separation. Separator, low-pressure separator, after cooling and separation, the hydrogen-rich gas is recycled, and the liquid product enters the fractionation system to be separated into gasoline fraction and diesel fraction. The nitride content in the product is 8.9μg / g, and the denitrification rate is as high as 99.2%. Control the saturation depth of aromatics in the first reaction zone, that is, compared with diesel feedstock oil, the saturation rate of aromatics with double rings or more in the reaction effluent of the first reaction zone is 67.3%, and the reaction effluent in the first reaction zone Based on the liquid component, the conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com