Barium ferrite composite material and preparation method and application thereof

A technology of composite materials and barium ferrite, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor dielectric properties and unsatisfactory wave-absorbing properties, and achieve good dielectric properties, easy industrial production, The effect of uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation steps of barium ferrite composite material:

[0042] (1) Preparation of amorphous nano-silica powder: Mix 1.86mL tetraethyl orthosilicate and 8.63mL absolute ethanol under stirring conditions, add 0.43mL diethanolamine, stir well, add 0.10mL deionized water dropwise, and age Gel was formed after curing for 5 hours, and vacuum-dried at 80°C for 2 hours to obtain amorphous nano-silica powder;

[0043] (2) 12.10g of Ba(NO 3 ) 2 and 219.12g of Fe(NO 3 ) 3 9H 2 O is respectively made into an aqueous solution of 0.05mol / L, and mixes uniformly to obtain a mixed solution (molar ratio Ba 2+ : Fe 3+ =1:11.7), add 122.23g citric acid (molar ratio citric acid: Ba 2+ =13.7) Mix evenly, gradually add ammonia water dropwise to adjust the pH value to 7, add 0.5 g of amorphous nano-silicon dioxide powder, sonicate for 10 minutes, stir in a water bath at 80 ° C, and evaporate the water to obtain a wet gel;

[0044] (3) The wet gel was vacuum-dried at 110°C, ignited in...

Embodiment 2

[0049] Preparation steps of barium ferrite composite material:

[0050] (1) Preparation of amorphous nano-silica powder: Mix 5.57mL tetraethyl orthosilicate and 25.90mL absolute ethanol under stirring conditions, add 1.30mL diethanolamine, stir well, add 0.30mL deionized water dropwise, and age Gel was formed after curing for 5 hours, and vacuum-dried at 80°C for 4 hours to obtain amorphous nano-silica powder;

[0051] (2) 11.86g of Ba(NO 3 ) 2 and 214.69g of Fe(NO 3 ) 3 9H 2 O is respectively made into an aqueous solution of 0.05mol / L, and mixes uniformly to obtain a mixed solution (molar ratio Ba 2+ : Fe 3+ =1:11.7), add 119.76g citric acid (molar ratio citric acid: Ba 2+ =13.7) Mix evenly, gradually add ammonia water dropwise to adjust the pH value to 7, add 1.5 g of amorphous nano-silicon dioxide powder, sonicate for 10 minutes, stir in a water bath at 80°C, and evaporate the water to obtain a wet gel;

[0052] (3) The wet gel was vacuum-dried at 110°C, ignited in ...

Embodiment 3

[0055] Preparation steps of barium ferrite composite material:

[0056] (1) Preparation of amorphous nano-silica powder: Mix 9.28mL tetraethyl orthosilicate and 43.17mL absolute ethanol under stirring conditions, add 2.16mL diethanolamine, stir well, add 0.50mL deionized water dropwise, and Gel was formed after curing for 5 hours, and vacuum-dried at 80°C for 6 hours to obtain amorphous nano-silica powder;

[0057] (2) 11.61g of Ba(NO 3 ) 2 and 210.27g of Fe(NO 3 ) 3 9H 2 O is respectively made into an aqueous solution of 0.05mol / L, and mixes uniformly to obtain a mixed solution (molar ratio Ba 2+ : Fe 3+ =1:11.7), add 117.29g citric acid (molar ratio citric acid: Ba 2+ =13.7) Mix well, gradually add ammonia water dropwise to adjust the pH value to 7, add 2.5g of amorphous nano-silicon dioxide powder, sonicate for 10 minutes, stir in a water bath at 80°C, and volatilize the water to obtain a wet gel;

[0058] (3) The wet gel was vacuum-dried at 110°C, ignited in air fo...

PUM

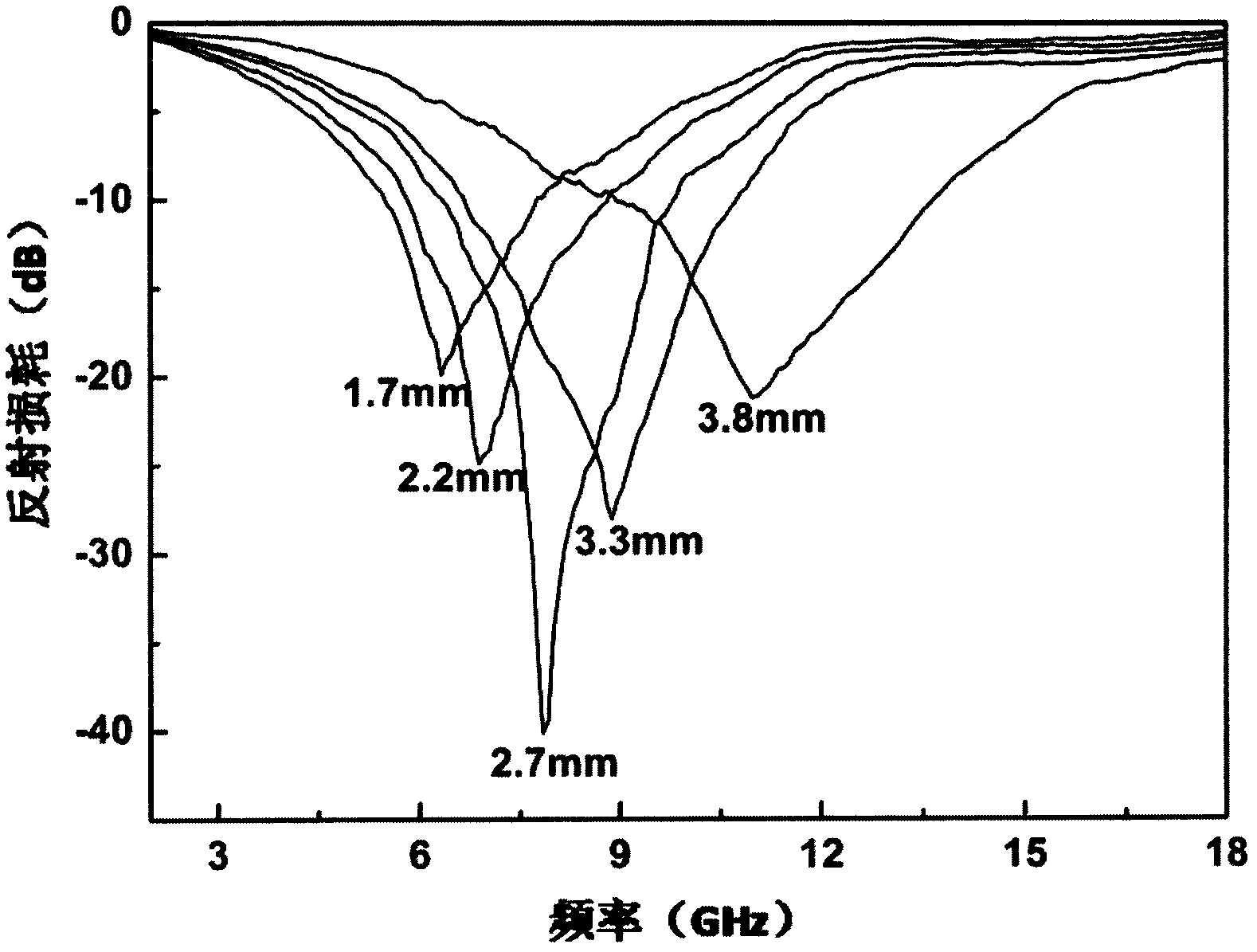

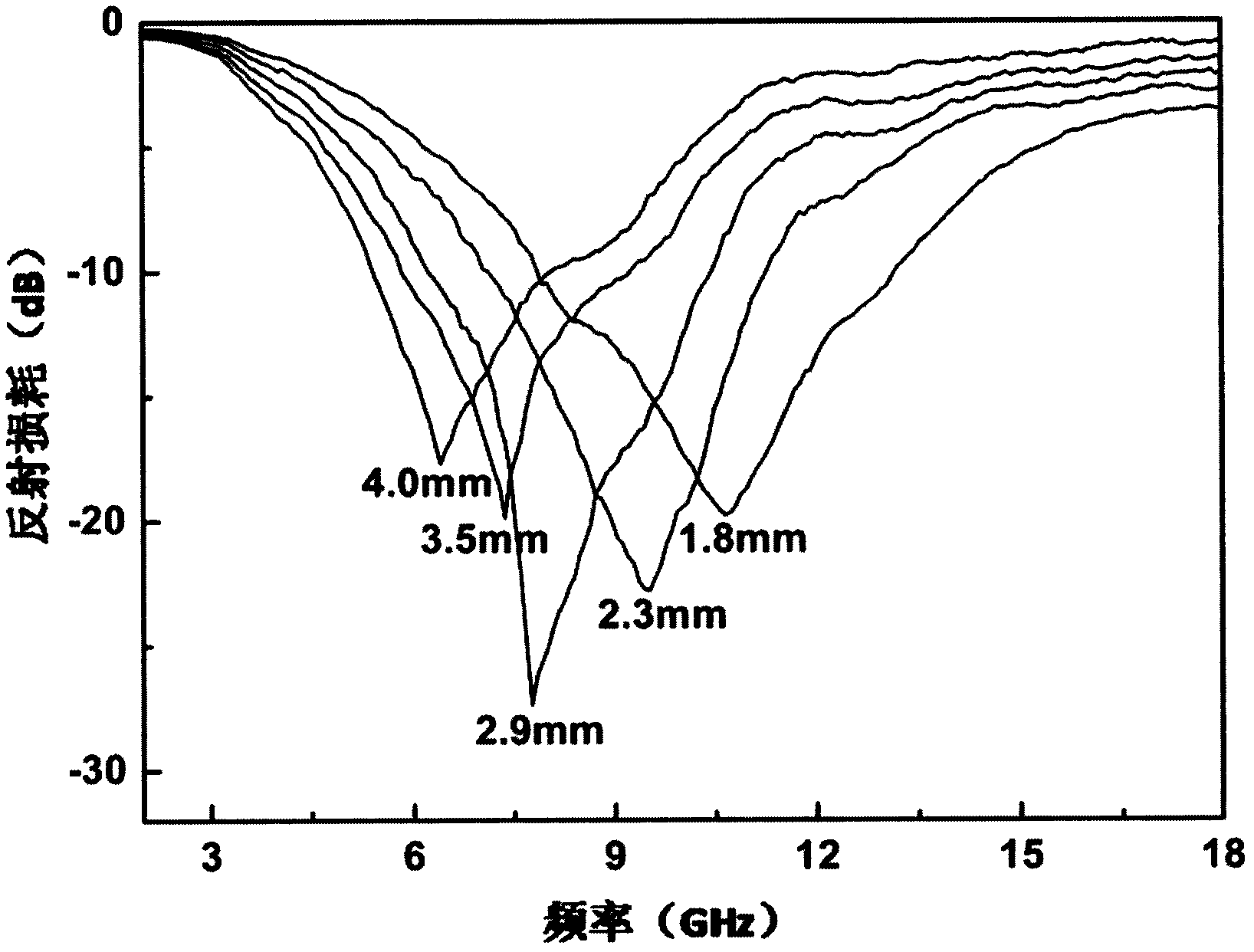

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com