Preparation method of anti-reflection thin film with photo-transformation function

An anti-reflection and light conversion technology, applied in the field of anti-reflection films, can solve the problems of low solar cell conversion efficiency, high cost of vacuum deposition technology, poor film wear resistance, etc., to improve photoelectric conversion efficiency, easy industrial production, and weather resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

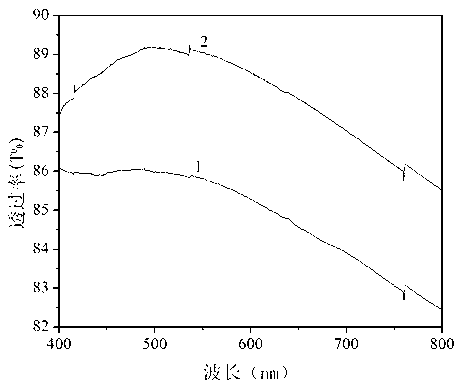

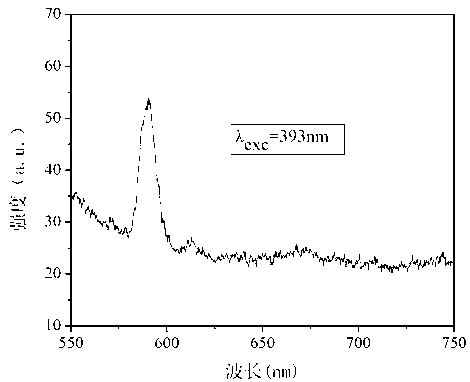

Image

Examples

Embodiment 1

[0020] 1) Dissolve europium nitrate hexahydrate and ethyl orthosilicate in absolute ethanol respectively, and drop the solution of europium nitrate hexahydrate in absolute ethanol into ethyl orthosilicate in absolute ethanol under stirring to make Eu 3+ The molar ratio with tetraethyl orthosilicate is 1:10, and the pH is adjusted to 5.5 to obtain a photofunctional sol;

[0021] 2) Under stirring, add the nano-silica hydrosol with a mass concentration of 30% to the polyvinyl alcohol 1788 deionized aqueous solution with a mass concentration of 3% dropwise, so that the mass concentration of silica is 6%, and adjust the pH to 10.0, the matrix sol was obtained;

[0022] 3) Mix the optical functional sol in step 1) and the matrix sol in step 2) evenly at a mass ratio of 1.8:98.2, seal, age, and set aside;

[0023] 4) Coat the mixed sol in step 3) on the glass substrate by spin coating method, so that the thickness of the film layer is 90nm, after drying, place it in a muffle furnac...

Embodiment 2

[0026] 1) Dissolve europium nitrate hexahydrate and ethyl orthosilicate in absolute ethanol respectively, and drop the solution of europium nitrate hexahydrate in absolute ethanol into ethyl orthosilicate in absolute ethanol under stirring to make Eu 3+ The molar ratio with tetraethyl orthosilicate is 1:10, and the pH is adjusted to 2.0 to obtain a photofunctional sol;

[0027] 2) Under stirring, add the nano-silica hydrosol with a mass concentration of 30% to the polyvinyl alcohol 1788 deionized aqueous solution with a mass concentration of 3% dropwise, so that the mass concentration of silica is 6%, and adjust the pH to 2.0, to obtain matrix sol;

[0028] 3) Mix the optical functional sol in step 1) and the matrix sol in step 2) uniformly at a mass ratio of 0.6:99.4, seal, age, and set aside;

[0029] 4) Coat the mixed sol in step 3) on the glass substrate by spraying method, so that the thickness of the film layer is 150nm, after drying, place it in a muffle furnace and he...

Embodiment 3

[0032] 1) Dissolve europium nitrate hexahydrate and ethyl orthosilicate in absolute ethanol respectively, and drop the solution of europium nitrate hexahydrate in absolute ethanol into ethyl orthosilicate in absolute ethanol under stirring to make Eu 3+ The molar ratio with tetraethyl orthosilicate is 1:10, and the pH is adjusted to 5.5 to obtain a photofunctional sol;

[0033] 2) Under stirring, add the nano-silica hydrosol with a mass concentration of 30% to the polyvinyl alcohol 1788 deionized aqueous solution with a mass concentration of 3% dropwise, so that the mass concentration of silica is 3%, and adjust the pH to 10.0, the matrix sol was obtained;

[0034] 3) Mix the optical functional sol in step 1) and the matrix sol in step 2) evenly at a mass ratio of 1.2:98.8, seal, age, and set aside;

[0035] 4) Coating the mixed sol in step 3) on the glass substrate by pulling method, so that the thickness of the film layer is 150nm, after drying, place it in a muffle furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com