Preparation of magnetic mesoporous carbon nitride adsorbent and method for removing perfluorooctane compound in water

A technology of mesoporous carbon nitride and perfluorooctane, applied in the field of adsorption, can solve the problems of difficult recycling and reuse of powdered mesoporous carbon nitride, and achieve sustainable development, simple operation process and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of mesoporous carbon nitride:

[0030] Weigh 0.5 g of SBA-15 and add it to 2.2 g of ethylenediamine and 5.4 g of carbon tetrachloride mixture, heat at reflux, then react at 90 °C for 6 h, and vacuum dry for 12 h; at a nitrogen flow rate of 50 mL / min At 3 °C / min, the temperature was raised to 400 °C, and kept at this temperature for 5 hours, the template was washed with 5wt% HF acid, filtered, washed several times with ethanol, and dried at 100 °C to obtain mesoporous carbon nitride;

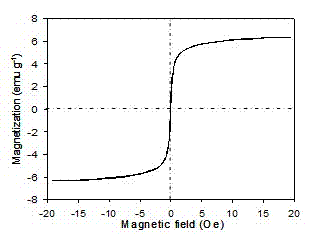

[0031] Preparation of Magnetic Mesoporous Carbon Nitride Adsorbent:

Embodiment 1

[0033] Add ferrous ammonium sulfate and ferric ammonium sulfate with a molar ratio of 1:2 and 1.25 g of mesoporous carbon nitride to 100 mL of water to prepare a suspension, and ultrasonically disperse it evenly; transfer the above suspension to a constant temperature water bath In the process, under the conditions of nitrogen flow and water bath temperature of 50°C, the pH value of the mixed solution was adjusted to 10-12 with 8 mol / L ammonia water for chemical precipitation reaction; the obtained product was first washed with distilled water until neutral, and then washed with absolute ethanol Washed, and finally vacuum-dried at 60 °C for 24 h to obtain Fe x o y A magnetic mesoporous carbon nitride adsorbent with a mass ratio of 1:5 to mesoporous carbon nitride.

Embodiment 2

[0037] In Example 1, other conditions remain unchanged, when the mass of mesoporous carbon nitride is 1.0 mg, Fe x o y Magnetic mesoporous carbon nitride with a mass ratio of 1:4 to mesoporous carbon nitride; when the mass of mesoporous carbon nitride is 0.5 mg, Fe x o y Magnetic mesoporous carbon nitride with a mass ratio of 1:2 to mesoporous carbon nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com