Curable epoxy resin composition

An epoxy resin, curable technology, used in electrical solid devices, semiconductor/solid state device parts, circuits, etc., can solve problems such as luminosity reduction, and achieve high quality and durability, and excellent reflow resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0139] (manufacture of rubber particles)

[0140] 500 g of ion-exchanged water and 0.68 g of sodium dioctyl sulfosuccinate were placed in a 1 L polymerization vessel equipped with a reflux cooler, and the temperature was raised to 80° C. while stirring under a nitrogen stream. Here, a monomer mixture containing 9.5 g of butyl acrylate, 2.57 g of styrene, and 0.39 g of divinylbenzene corresponding to about 5% by weight of the amount required to form a core portion was added at once, and stirred for 20 minutes. After emulsification, 9.5 mg of potassium peroxodisulfate was added, followed by stirring for 1 hour to conduct initial seed polymerization. Next, 180.5 mg of potassium peroxodisulfate was added, followed by stirring for 5 minutes. Here, 180.5 g of butyl acrylate and 48.89 g of styrene were added continuously for 2 hours to dissolve 0.95 g of dioctyl sodium sulfosuccinate in the amount required to form a core part (about 95% by weight). g. The monomer mixture formed in ...

manufacture example 2

[0145] (Manufacture of rubber particle dispersed epoxy compound)

[0146] In the state of heating 10 parts by weight of the rubber particles obtained in Production Example 1 to 60° C. under nitrogen flow, it was dispersed in the product name “CELLOXIDE 2021P” (3,4-epoxycyclohexyl In 70 parts by weight of methyl (3,4-epoxy) cyclohexane carboxylate, manufactured by Daicel Co., Ltd., vacuum defoaming was carried out to obtain a rubber particle-dispersed epoxy compound (viscosity at 25° C.: 624 mPa s).

[0147] It should be noted that using a digital viscometer (trade name "DVU-EII type", manufactured by Tokimec) to measure the rubber particle-dispersed epoxy compound (10 wt. Viscosity (viscosity at 25° C.) of the substance obtained from rubber particles in 10 parts.

manufacture example 3

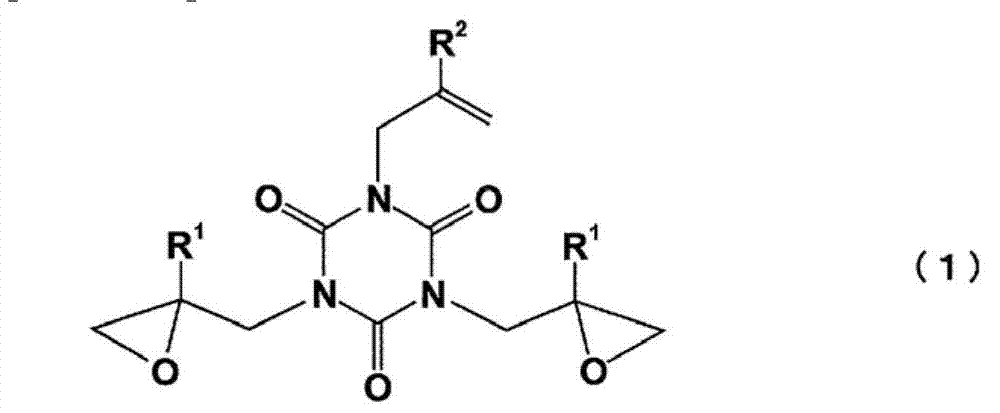

[0149] (Manufacture of epoxy resin: Examples 1 to 7, Comparative Examples 2 and 3)

[0150] According to the formula shown in Table 1 (mixing ratio) (unit: parts by weight), monoallyl diglycidyl isocyanurate (trade name "MA-DGIC", manufactured by Shikoku Chemical Industry Co., Ltd.) , alicyclic epoxy compound (trade name "CELLOXIDE2021P", manufactured by Daicel Co., Ltd.), rubber particle-dispersed epoxy resin obtained in Production Example 2, bisphenol A epoxy resin (trade name "YD-128" , Nippon Steel Chemical Co., Ltd.) were mixed, stirred at 80°C for 1 hour to dissolve monoallyl diglycidyl isocyanurate, and then, according to the formula shown in Table 1 (unit : parts by weight), polycarbonate diol (trade name "CD220PL", manufactured by Daicel Corporation) was mixed, and stirred at 60° C. for 1 hour to obtain an epoxy resin (mixture). In addition, "-" in Table 1 shows that the compounding of this component was not performed, and it is the same in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com