Tellurium-cadmium-mercury grid-controlled structure photoconductive detector for Hall test

A mercury cadmium telluride and structured light technology, which is applied in the direction of semiconductor devices, sustainable manufacturing/processing, electrical components, etc., to achieve the effect of shortening the development process and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

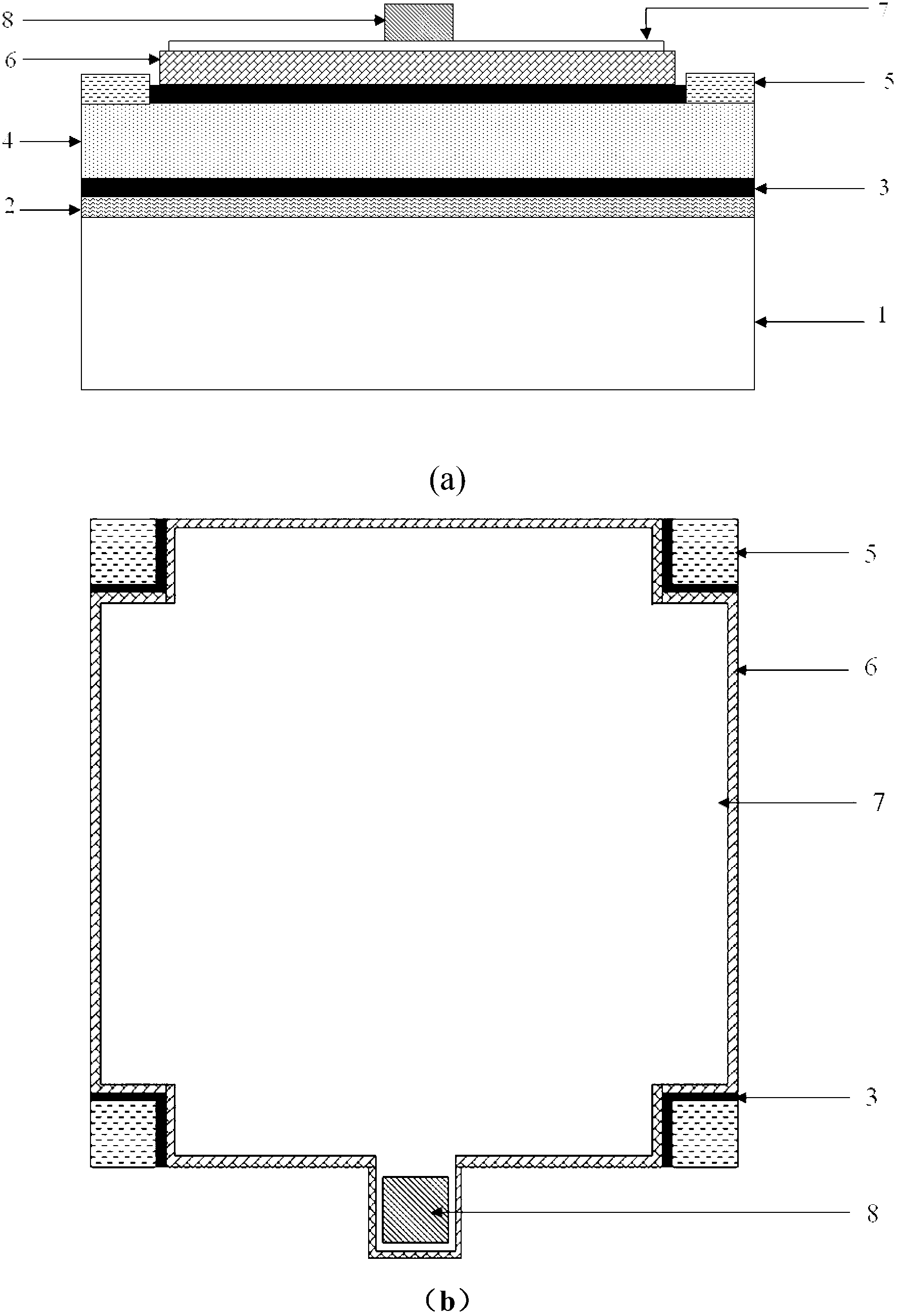

[0018] Step 1: De-damaging the flatness of the first surface of the n-type HgCdTe material 4, wherein Hg 1-x Cd x In Te, x=0.21, at liquid nitrogen temperature, the mobility is about 3×10 4 cm 2 / (V s), the electron concentration is about 1×10 13 cm -3 . An anodized layer 3 with a thickness of 80 nm is grown on its surface.

[0019] Step 2: Paste the processed side of the mercury cadmium telluride material 4 with the sapphire substrate 1 with the prepared epoxy resin glue 2, and fully cure under pressure at a certain temperature (about 60°C) under vacuum to ensure The adhesive layer is within a certain uniform thickness range, and the curing time is about 90mins to ensure the adhesive strength.

[0020] Step 3: Paste the processed chip on the first side on the ground glass plate with wax, and then flatten it with a vacuum silicon wafer machine (to ensure that the thickness difference is within 3 μm), and make the other side of the mercury cadmium telluride material In t...

example 2

[0030] Step 1: De-damaging the flatness of the first surface of the n-type HgCdTe material 4, wherein Hg 1-x Cd x In Te, x=0.26, at liquid nitrogen temperature, the mobility is about 1×10 5 cm 2 / (V·s), the electron concentration is about 2×10 14 cm -3 . An anodized layer 3 with a thickness of 90 nm is grown on its surface.

[0031] Step 2: Paste the processed side of the mercury cadmium telluride material 4 with the sapphire substrate 1 with the prepared epoxy resin glue 2, and fully cure under pressure at a certain temperature (about 60°C) under vacuum to ensure The adhesive layer is within a certain uniform thickness range, and the curing time is about 90mins to ensure the adhesive strength.

[0032] Step 3: Paste the processed chip on the first side on the ground glass plate with wax, and then flatten it with a vacuum silicon wafer machine (to ensure that the thickness difference is within 3 μm), and make the other side of the mercury cadmium telluride material Thin...

example 3

[0042] Step 1: De-damaging the flatness of the first surface of the n-type HgCdTe material 4, wherein Hg 1-x Cd x In Te, x=0.23, at liquid nitrogen temperature, the mobility is about 5×10 4 cm 2 / (V s), the electron concentration is about 1×10 15 cm -3 . An anodized layer 3 with a thickness of 100 nm is grown on its surface.

[0043] Step 2: Paste the processed side of the mercury cadmium telluride material 4 with the sapphire substrate 1 with the prepared epoxy resin glue 2, and fully cure under pressure at a certain temperature (about 60°C) under vacuum to ensure The adhesive layer is within a certain uniform thickness range, and the curing time is about 90mins to ensure the adhesive strength.

[0044] Step 3: Paste the processed chip on the first side on the ground glass plate with wax, and then flatten it with a vacuum silicon wafer machine (to ensure that the thickness difference is within 3 μm), and make the other side of the mercury cadmium telluride material Thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electron concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com