Continuous filament reinforced plastic impregnation uniformity evaluation method

A technology of reinforced plastics and continuous fibers, which is applied in the field of qualitative evaluation of the impregnation effect of continuous fiber prepreg tapes, can solve the problems that the impregnation uniformity cannot be quantitatively evaluated, the final effect cannot be explained, and the impregnation degree characterization method is not given. Calculation method Direct, impregnated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

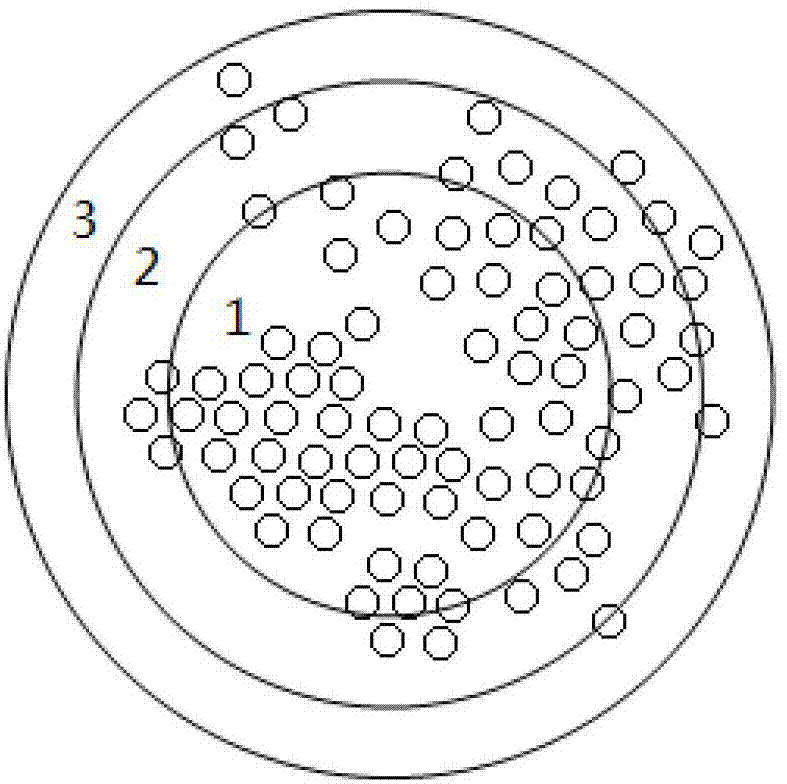

[0038] The method for evaluating the impregnation uniformity of continuous fiber reinforced plastics includes the following steps:

[0039] (1) Take the impregnated sample, and cut a section of the sample. During the cutting process, prevent the sample from cracking; the sample is a cylindrical structure, the cross-sectional shape of the sample is circular, and the length of the cut sample is 10mm.

[0040] (2) Wet-grind the sample on the grinding machine with water abrasive paper from coarse to fine under running water, and then polish it with polishing fabric and polishing paste on the polishing machine until the cross-sectional shape of the sample is clearly visible under the microscope;

[0041] The sandpaper is 300#, 500#, 800# respectively.

[0042] If necessary, use an ultrasonic cleaner to clean the surface of the sample to remove the residual polishing paste.

[0043] (3) Place the sample under an optical microscope for microscopic examination;

[0044] Place the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com