Fluorescent sensor for determining serum protein concentration and manufacturing method thereof

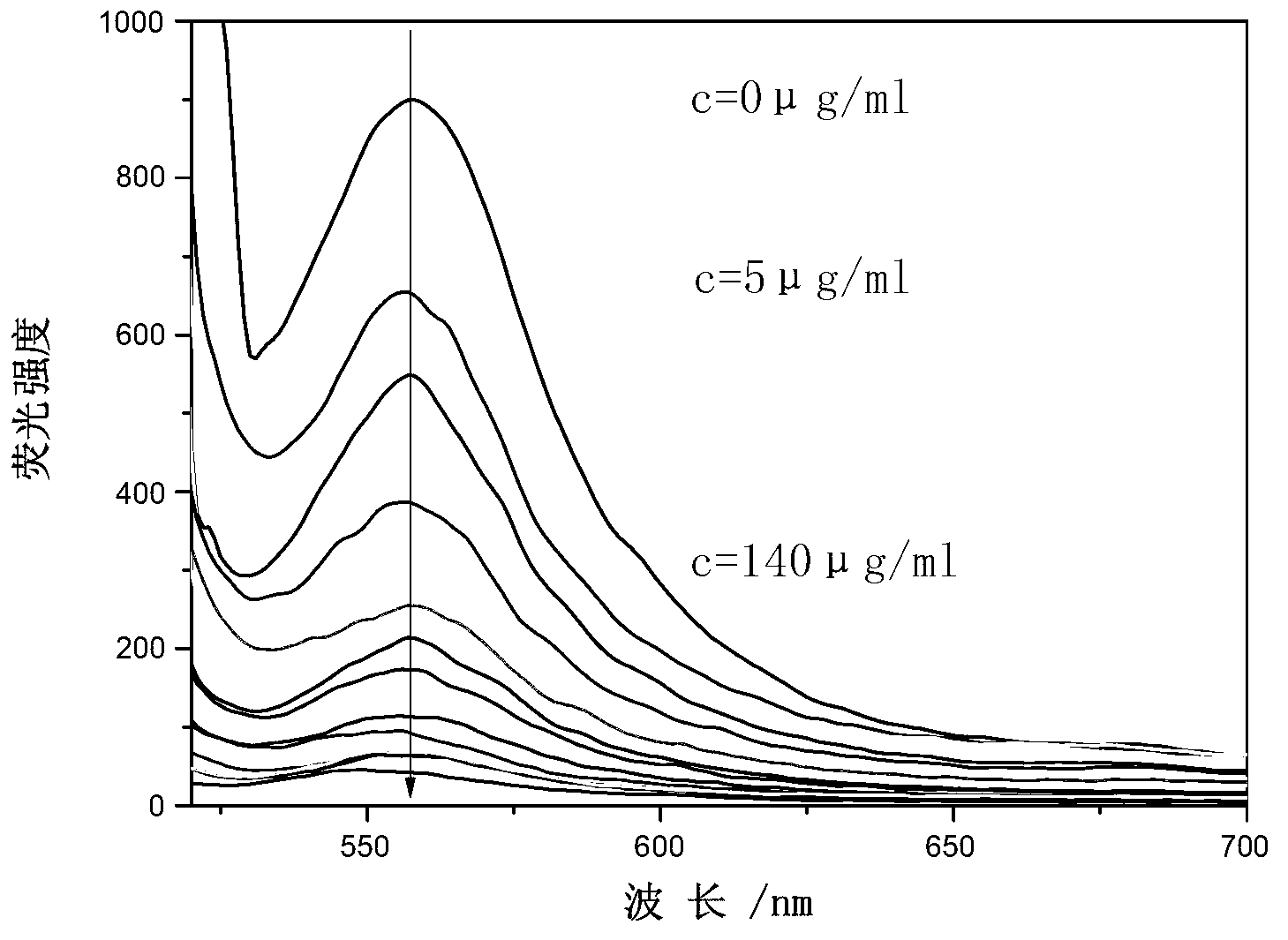

A fluorescent sensor and serum protein technology, which is applied in the field of sensor preparation, can solve the problem of low selectivity of serum protein, and achieve the effects of good biocompatibility, long storage time, and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

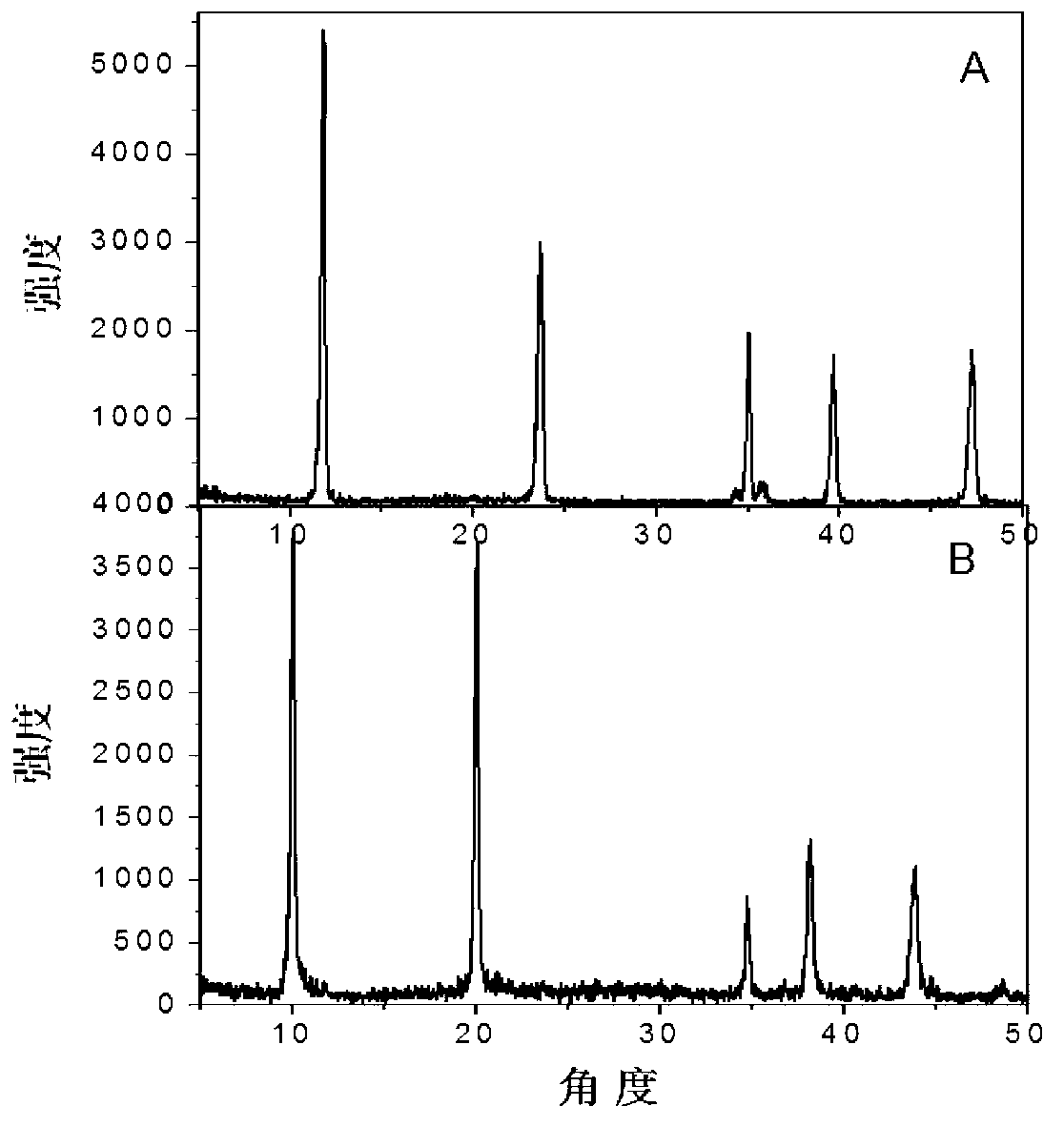

[0026] 1. Preparation of hydrotalcite precursor: weigh 5.128gMg(NO 3 ) 2 ·6H 2 O, 3.7513gAl(NO 3 ) 3 9H 2 O and 6.006g of urea were dissolved in 100ml of deionized water to prepare a salt solution, then transferred to a high-pressure reactor, reacted at 110°C for 12h, centrifuged and washed the product, and the chemical formula was Mg 2 Al(OH) 6 (CO 3 )·6H 2 Hydrotalcite of O; take 1g of hydrotalcite and add 200ml to remove CO 2 In the water, stir for 1h to swell, then add sodium nitrate solution and stir for 0.5h, the sodium nitrate solution is 127gNaNO 3 Dissolve in 300ml to remove CO 2 prepared in water; then slowly add 350 μl concentrated nitric acid with a pipette gun, stir for 48 hours, and centrifuge twice with ethanol to obtain Mg 2 Al(OH) 6 (NO 3 )·6H 2 O hydrotalcite precursor;

[0027] 2. Take the Mg prepared in step 1 2 Al(OH) 6 (NO 3 )·6H 2 O hydrotalcite precursor 0.10g, add in the flask that 100ml formamide is housed, under N2 Stirring and reac...

Embodiment 2

[0044] 1. Same as implementation case 1;

[0045] 2. Take the Mg prepared in step 1 2 Al(OH) 6 (NO 3 )·6H 2 O hydrotalcite precursor 0.11g, add in the flask that 110ml formamide is housed, under N 2 Stirring and reacting for 45 hours under protection, centrifuging to obtain the hydrotalcite laminate colloid solution after peeling;

[0046] 3. The preparation concentration is 2×10 -5 The aqueous solution of erythrosin B sodium salt of mol / L is adjusted to pH 7.5 with NaOH, and stored in a volumetric flask in the dark;

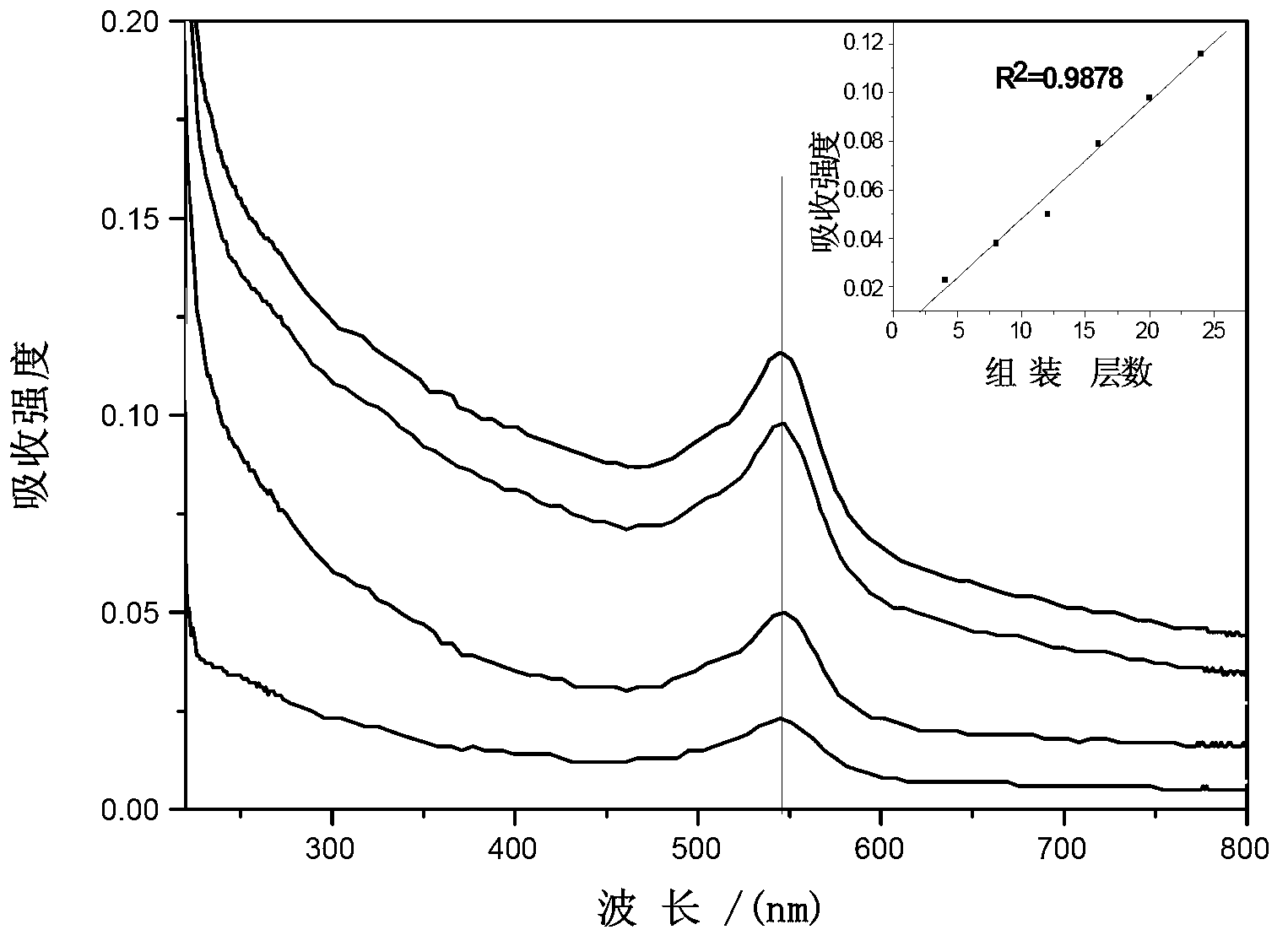

[0047] 4. Take a 3cm×1cm quartz plate and use concentrated H with a volume ratio of 7:3 2 SO 4 and H 2 o 2 Wash with the mixed solution of ethanol, and then ultrasonically use ethanol for 3 times, each time for 20 minutes, to obtain a quartz sheet rich in hydroxyl groups on the surface, and then place it in the hydrotalcite laminate colloid solution prepared in step 2 for 20 minutes for pre-assembly, take it out and use Rinse with deionized water and d...

Embodiment 3

[0051] 1. Same as implementation case 1;

[0052] 2. Take the Mg prepared in step 1 2 Al(OH) 6 (NO 3 )·6H 2 O hydrotalcite precursor 0.13g, add in the flask that 130ml formamide is housed, under N 2 Stirring and reacting for 50 hours under protection, centrifuging to obtain the hydrotalcite laminate colloid solution after peeling off;

[0053] 3. The preparation concentration is 3×10 -5 The aqueous solution of erythrosin B sodium salt of mol / L is adjusted to pH 7 with NaOH, and stored in a volumetric flask in the dark;

[0054] 4. Take a 3cm×1cm quartz plate and use concentrated H with a volume ratio of 7:3 2 SO 4 and H 2 o 2 Wash with the mixed solution of ethanol, and then ultrasonically use ethanol for 4 times, each time for 25 minutes, to obtain a quartz sheet rich in hydroxyl groups on the surface, and then place it in the hydrotalcite laminate colloid solution prepared in step 2 for 22 minutes for pre-assembly, take it out and use Rinse with deionized water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com