Method of removing oxide film on surface of copper or copper-base alloy and copper or copper-base alloy recovered using the method

An oxide film, copper-based alloy technology, applied in the improvement of process efficiency, instruments, optics, etc., to achieve the effects of increased electrolysis efficiency, reduced size, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

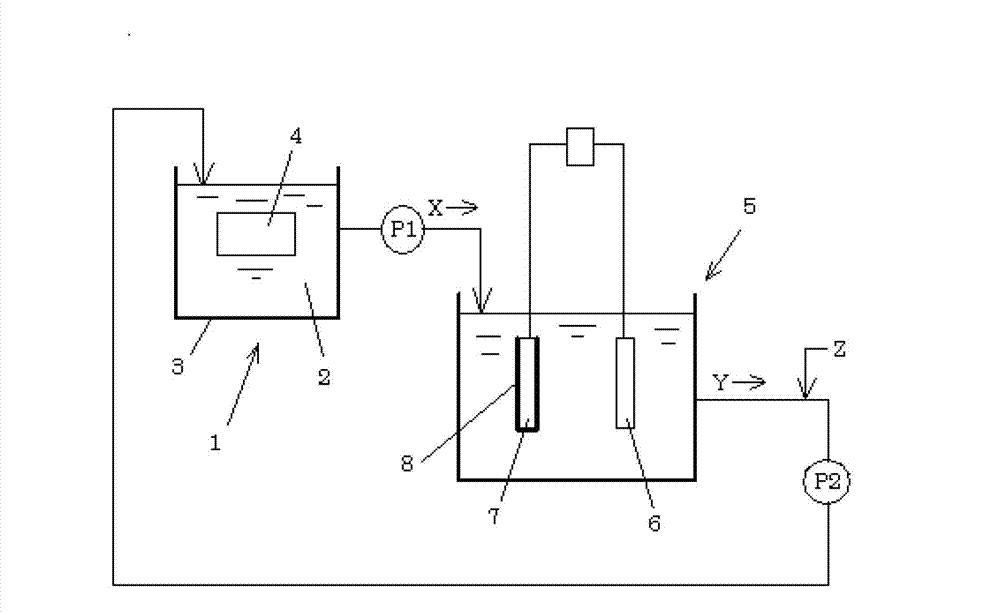

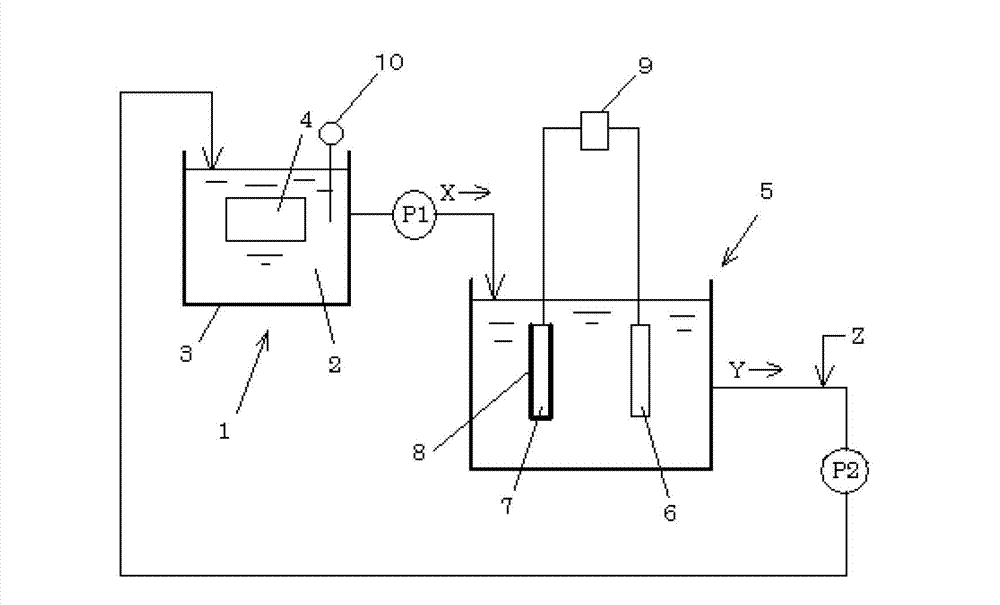

[0035] figure 1 It is a schematic diagram of a device for implementing a corresponding embodiment of the present invention. In the oxide film removal device 1 of the present invention, copper or copper-based alloy 4 is immersed in the pickling that is full of the oxide film on the surface of copper or copper-based alloy. In the pickling tank 3 of the liquid 2, the oxide film on the surface is removed in the pickling liquid 2. Although the oxide film also depends on the degree of heat treatment in the previous process, the thickness is 0.05-10 μm, the temperature of the pickling solution 2 for the oxide film is preferably 30-60°C, and the immersion time is preferably 30-120 minutes. The copper or copper-based alloy 4 from which the oxide film has been removed is carried out from the pickling tank 3 and supplied to the next step.

[0036] Pickling solution 2 contains 50-400g / L of sulfuric acid; 1-100g / L of at least one oxidizing agent selected from nitric acid, hydrogen peroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com