Polyolefin/styrene resin composition and preparation method thereof

A technology of styrene-based resin and polyolefin, which is applied in the field of polyolefin/styrene-based resin composition and its preparation, can solve the problems of more expensive, poor compatibility, and poor material performance, and achieve excellent strength and flame retardancy effect, good toughness and chemical resistance, mechanically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

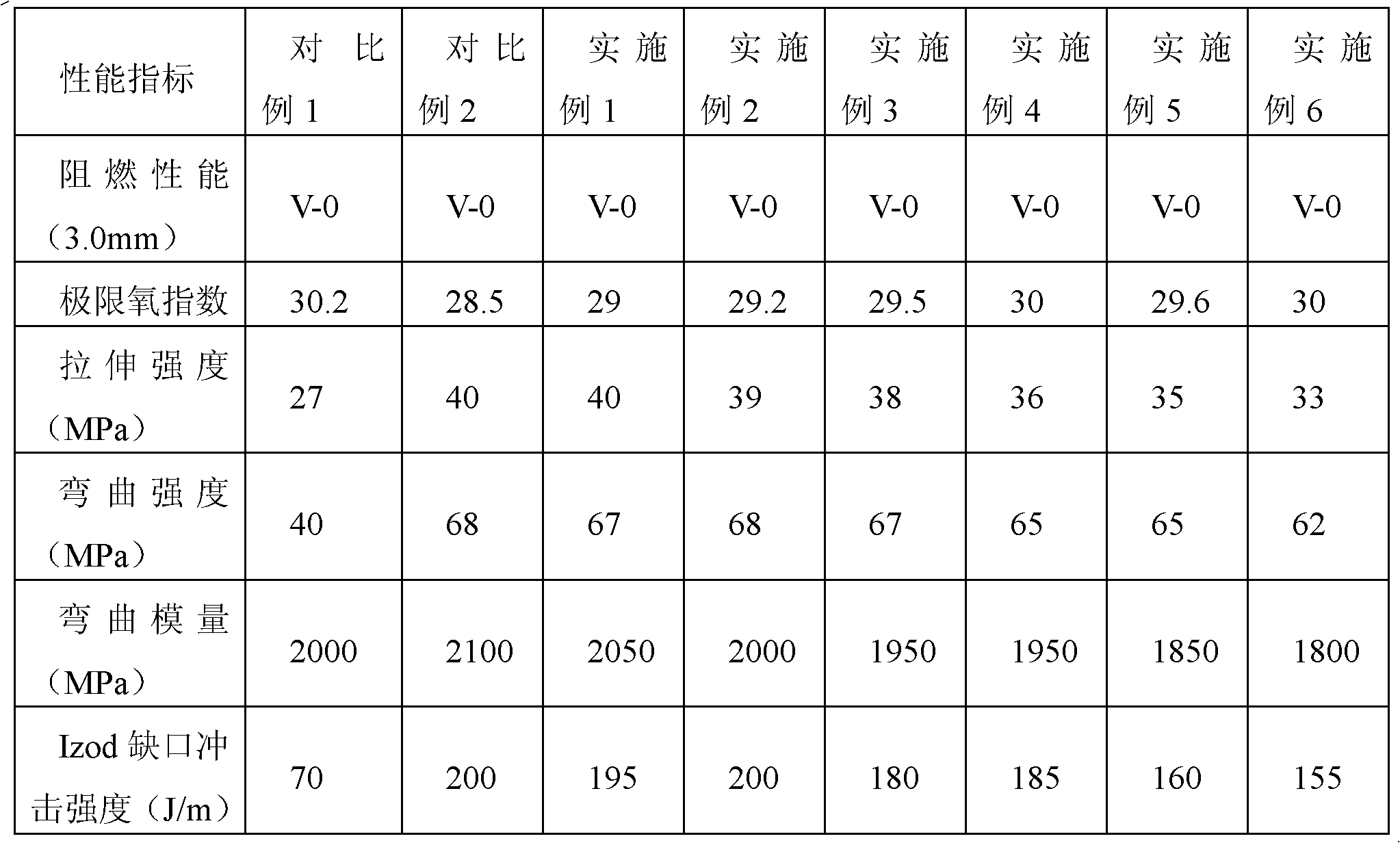

Examples

Embodiment 1

[0041] (1) Weigh 100 parts of polyolefin, 650 parts of acrylonitrile-butadiene-styrene graft copolymer, 30 parts of compatibilizer II, 40 parts of toughening agent II, 100 parts of flame retardant, synergistic flame retardant 40 parts of anti-oxidant, 40 parts of compound flame retardant, 5 parts of reinforcing agent, 5 parts of processing aid EBS, 2 parts of main anti-oxidation auxiliary agent and 3 parts of auxiliary anti-oxidation auxiliary agent.

[0042] (2) polyolefin, acrylonitrile-butadiene-styrene copolymer, compatibilizer, toughening agent, antioxidant aid, flame retardant, synergistic flame retardant, processing Put the additives together into a high-speed mixer with a rotation speed of 150 rpm and mix thoroughly for 3 minutes.

[0043] (3) Use a precise metering and conveying device to send the mixed material in the second step into the twin-screw extruder, and through the shearing action of the screw, fully mix, wherein the aspect ratio of the twin-screw extruder ...

Embodiment 2

[0046] (1) Weigh 200 parts of polyolefin, 550 parts of acrylonitrile-butadiene-styrene graft copolymer, 50 parts of compatibilizer II, 40 parts of toughening agent I, 80 parts of flame retardant, synergistic flame retardant 40 parts of anti-oxidant, 35 parts of compound flame retardant, 10 parts of reinforcing agent, 5 parts of processing aid EBS, 2 parts of main antioxidant auxiliary agent and 3 parts of auxiliary antioxidant.

[0047](2) polyolefin, acrylonitrile-butadiene-styrene copolymer, compatibilizer, toughening agent, flame retardant, synergistic flame retardant, antioxidant aid, processing Put the additives together into a high-speed mixer with a rotation speed of 150 rpm and mix thoroughly for 3 minutes.

[0048] (3) Use a precise metering and conveying device to send the mixed material in the second step into the twin-screw extruder, and through the shearing action of the screw, fully mix, wherein the aspect ratio of the twin-screw extruder is 40 , the screw speed...

Embodiment 3

[0051] (1) Weigh 300 parts of polyolefin, 450 parts of acrylonitrile-butadiene-styrene graft copolymer, 30 parts of compatibilizer I, 30 parts of compatibilizer II, 40 parts of toughening agent I, flame retardant 80 parts, 40 parts of synergistic flame retardant, 25 parts of compound flame retardant, 15 parts of reinforcing agent, 5 parts of processing aid PETS, 2 parts of main antioxidant auxiliary agent and 3 parts of auxiliary antioxidant.

[0052] (2) polyolefin, acrylonitrile-butadiene-styrene copolymer, compatibilizer, toughening agent, flame retardant, synergistic flame retardant, antioxidant aid, processing Put the additives together into a high-speed mixer with a rotation speed of 150 rpm and mix thoroughly for 3 minutes.

[0053] (3) Use a precise metering and conveying device to send the mixed material in the second step into the twin-screw extruder, and through the shearing action of the screw, fully mix, wherein the aspect ratio of the twin-screw extruder is 40 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com