Efficient multifunctional energy-saving stove

A multi-functional energy-saving stove, high-efficiency technology, applied in the field of energy-saving stoves, can solve the problems of low waste heat utilization rate and no promotional significance, and achieve the effect of good water replenishment and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

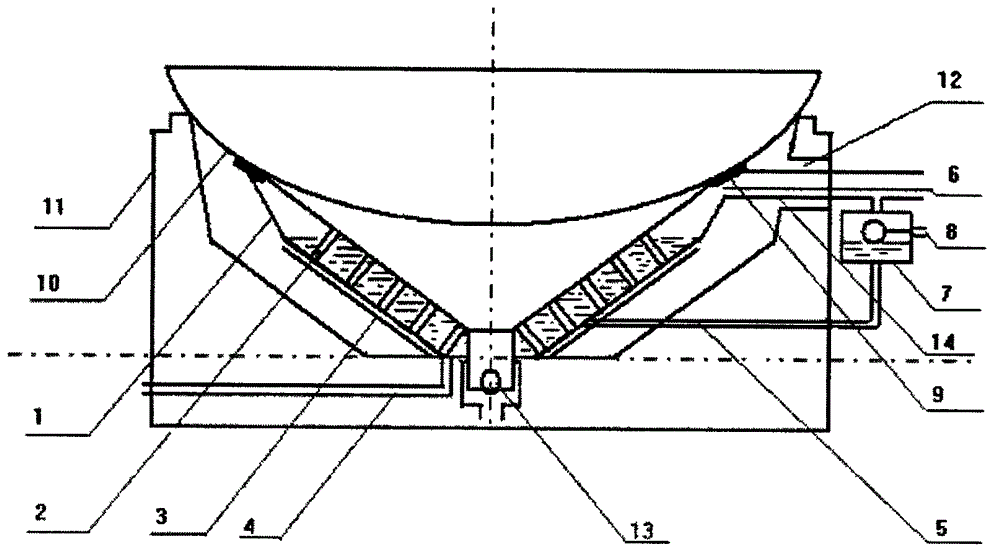

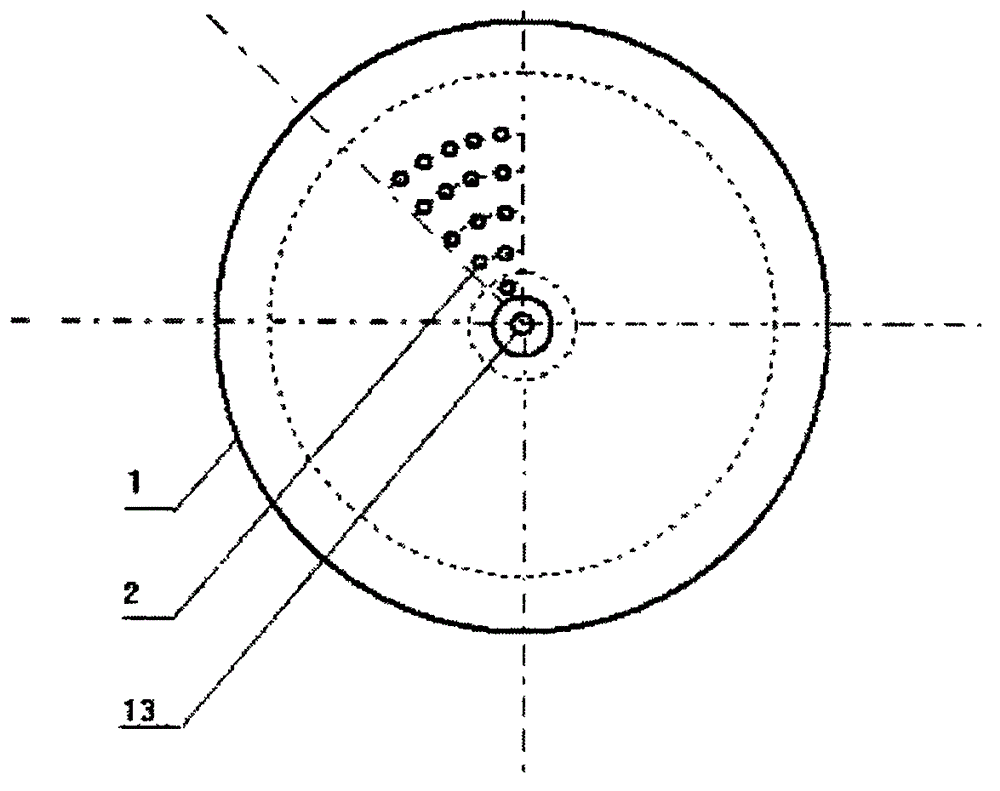

[0009] When in use, after the burner core 13 with blast burns the fuel, smoke is produced, which flows through the recirculation hole 2 together with the flame returned by contacting the bottom of the pan, and is discharged from the range body from the flue after passing through the gas barrier heat shield. Insulation pads prevent hot air from escaping and ensure flue gas flow to the water jacket. The water jacket is a closed component, which is replenished by the water inlet pipe. The heated hot water is released from the hot water pipe, and the steam generated by heating is connected through the steam pipe. The steam pipe cannot be equipped with a fully closed valve to ensure that the water jacket is under low pressure. The water jacket is connected with the steam pipe and the ball float valve box, so that the replenishment water level in the ball float valve box is consistent with the water jacket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com