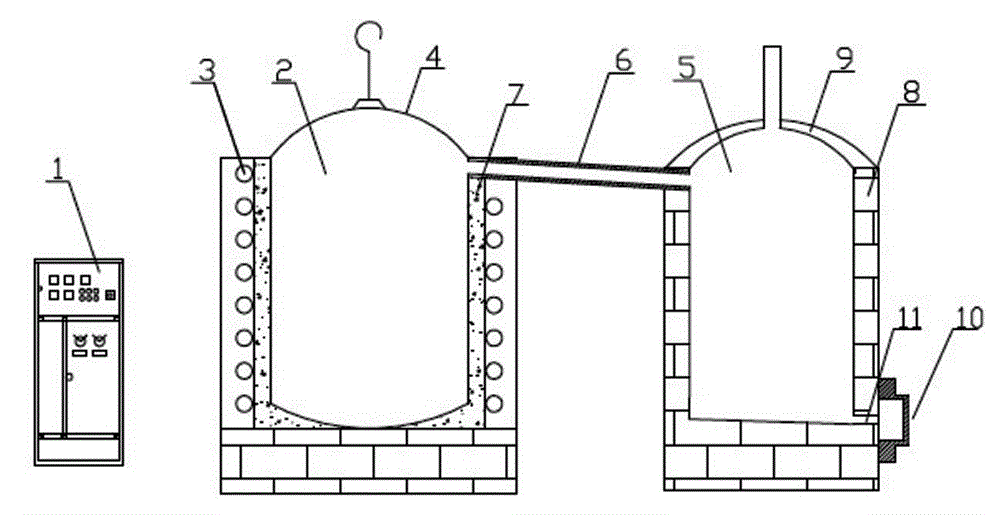

Method for separating and recycling zinc from secondary zinc resource by using distilling-condensing device

A technology for separation and recovery of secondary resources, applied in the field of metallurgy for the separation and recovery of zinc from secondary zinc resources, and the extraction of metallic zinc, which can solve the problems of various physical occurrence states and complex chemical composition of secondary zinc materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Take 1000Kg hot-dip galvanizing slag raw material, containing 93.5% zinc, 3.5% iron, 1.3% aluminum, 0.42% lead, 0.037% silicon, 0.012% magnesium, 0.025% tin, and 0.01% copper. Use a crane to open the sealing cover of the evaporation tank, add hot zinc slag raw materials into the evaporation tank, cover the sealing cover, and seal it. Turn on the power switch, heat up, and when heating for 120 minutes, the temperature in the distillation tank reaches 900°C, and the temperature is kept at a constant temperature through the automatic adjustment of the electrical control cabinet, and the constant temperature time is 10 hours. Then turn off the power switch to reduce the temperature in the evaporation tank to about 450°C. Open the working side door of the lower part of the condenser, release the zinc liquid and cast ingots to obtain 820.4Kg of zinc ingots. After the molten zinc ingot casting is completed, continue to automatically cool the furnace body to 200-3...

Embodiment 2

[0015] Example 2: Take 1000Kg hard zinc raw material, containing 84.3% zinc, 12.6% lead, 0.11% indium, and 1.62% iron. Use a crane to open the sealing cover of the evaporation tank, add the hard zinc raw material into the evaporation tank, cover the sealing cover, and seal it. Turn on the power switch and heat up. After heating for 150 minutes, the temperature in the evaporation tank reaches 1000°C. The temperature is automatically adjusted by the electrical control cabinet to keep the temperature at a constant temperature. The constant temperature time is 8 hours. Then turn off the power switch to reduce the temperature in the evaporation tank to about 470°C. Open the working side door of the lower part of the condenser, release the zinc liquid and cast ingots to obtain 775.1Kg of zinc ingots. After the zinc liquid is put, continue to make the furnace body automatically cool down to 200-300°C, open the round arched sealing cover of the evaporation tank, and take out 223.5K...

Embodiment 3

[0016] Example 3: Take 1000Kg zinc-tin alloy, containing 76.3% zinc, 21.5% tin, 1.1% lead, 0.2% iron, 0.3% copper, and 0.1% calcium. Use a crane to open the sealing cover of the evaporation tank, add the zinc-tin alloy raw material into the evaporation tank, cover the sealing cover, and seal it. Turn on the power switch, heat up, and when heating for 120 minutes, the temperature in the evaporation tank reaches 950°C, and the temperature is kept constant through the automatic adjustment of the electrical control cabinet, and the constant temperature time is 8 hours. Then turn off the power switch to reduce the temperature in the evaporation tank to about 500°C. Open the working side door of the lower part of the condenser, release the zinc liquid and cast ingots to obtain 672.5Kg of zinc ingots. After the zinc liquid is put out, continue to make the furnace body automatically cool down to 200-300°C, open the round arched sealing cover of the evaporation tank, and take out 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com