Modification process of surface bionic self-assembly multilayer film of artificial lens and artificial lens provided with surface bionic self-assembly multilayer film

An intraocular lens and multi-layer film technology, used in coatings, prostheses, medical science, etc., can solve the problems of high price of antibody drugs, affecting application value, toxic side effects, etc., to achieve good tissue and cell compatibility, avoid Toxic side effects, high biocompatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Positively charged surface activation of intraocular lens materials

[0028] Choice of hard and soft intraocular lenses, the materials of which are polymethylmethacrylate, polydimethylsiloxane PDMS silicone rubber and polyhydroxyethylmethacrylate hydrogel. Immersion to 1×10 -5 mol / L 3-aminopropyltriethoxysilane ethanol-water mixed solution, hydrolyzed for 2 hours, the surface of the intraocular lens material has positively charged amino groups, cleaned with ethanol-water mixed solution, and blown dry with nitrogen gas for later use.

Embodiment 2

[0029] Example 2: Negatively charged surface activation of intraocular lens materials

[0030]Choice of hard and soft intraocular lenses, the materials of which are polymethylmethacrylate, polydimethylsiloxane PDMS silicone rubber and polyhydroxyethylmethacrylate hydrogel. The intraocular lens was treated with surface plasma on a plasma generator by heating and volatilizing glacial acetic acid as a gas source. First, the flow rate is 20sccm, the inner pressure of the chamber is 0.3Torr, and the power is 100w, and the chamber is purged with Ar gas for 10min. Then put the intraocular lens into the chamber of the plasma generator, and use the acetic acid gas plasma to activate the intraocular lens. The conditions are: gas flow rate 20sccm, chamber pressure 0.3Torr, processing power 100w, processing time 60s.

Embodiment 3

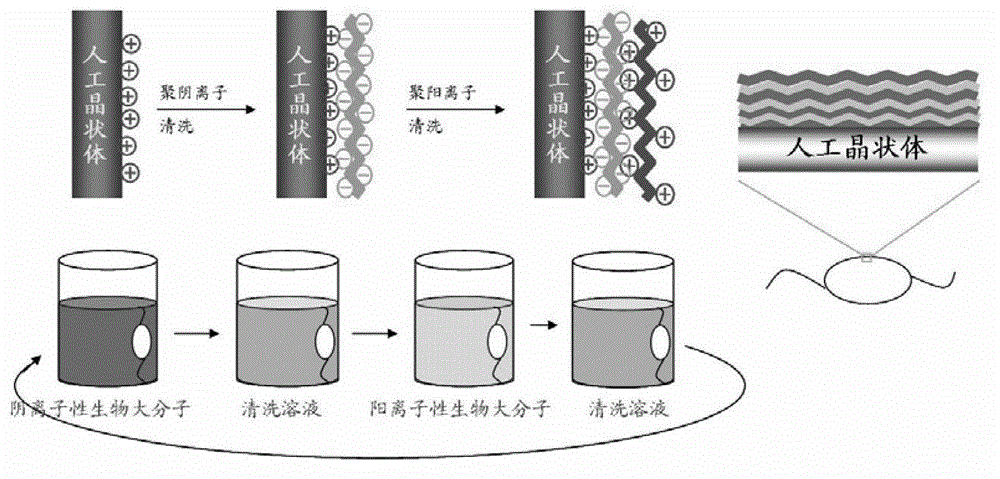

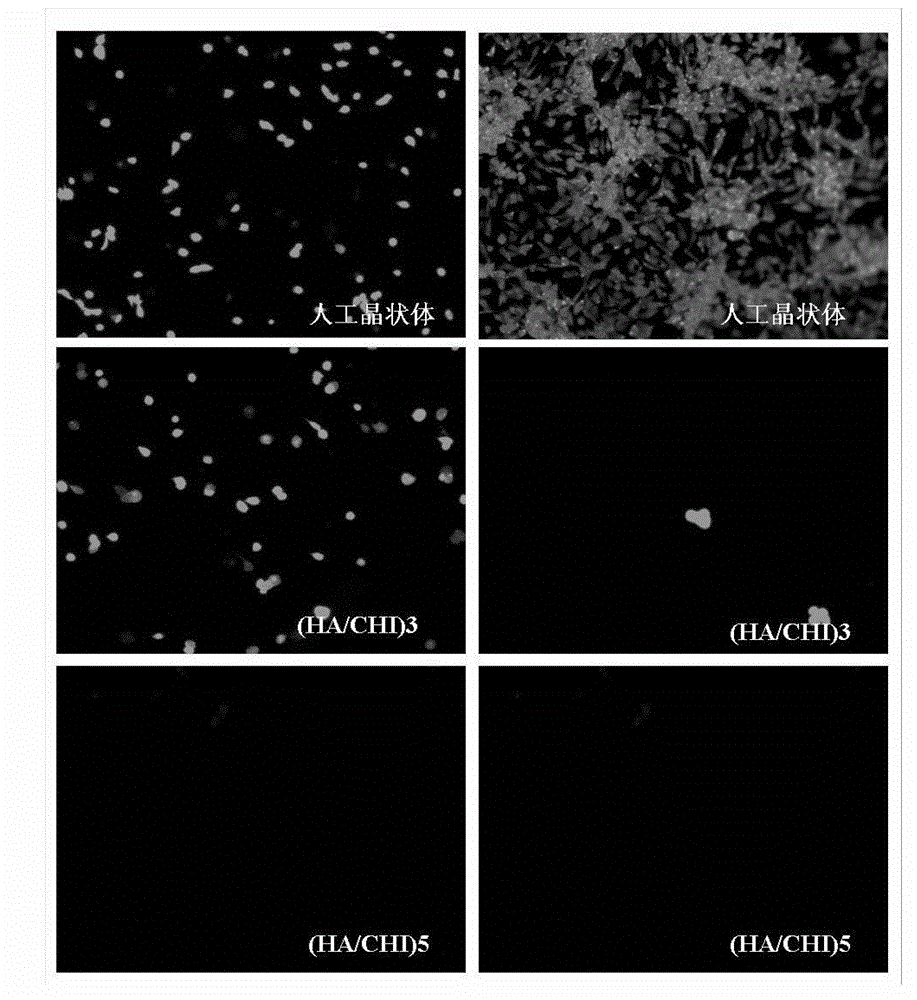

[0031] Example 3: Preparation of surface biomimetic self-assembly (hyaluronic acid / chitosan) multilayer film modified intraocular lens

[0032] The artificial lens after surface activation is taken, and its material can be one of polymethyl methacrylate, polydimethylsiloxane PDMS silicone rubber and polyhydroxyethyl methacrylate hydrogel. In this example, a soft polydimethylsiloxane PDMS silicone rubber intraocular lens was taken. After surface activation by the scheme of Example 1, it was immersed in a 1 mg / mL negatively charged biomacromolecule hyaluronic acid solution, and statically adsorbed. After 10 minutes, take it out and wash it with phosphate buffer solution; then immerse the hyaluronic acid-adsorbed intraocular lens into 2 mg / mL positively charged biomacromolecule chitosan solution, let it stand for electrostatic adsorption for 10 minutes, take it out and wash it with phosphate buffer solution Cleaning; alternately assemble (hyaluronic acid / chitosan) for 1 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com