Silicon oil for packaging LED (light-emitting diode) and preparation method thereof

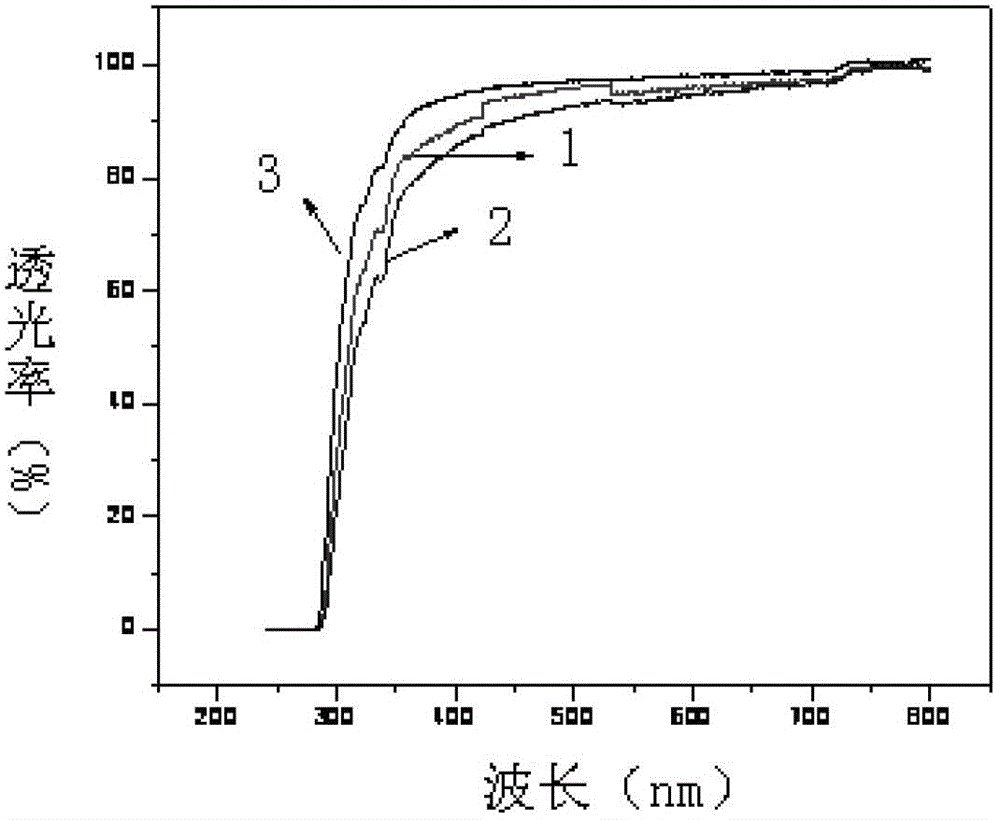

A technology of LED encapsulation and silicone oil, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low refractive index and light transmittance of basic polymer silicone oil, large difference in physical and chemical properties, and difficulty of transparent polymers. , to achieve the effect of balancing the ring-opening polymerization reaction, improving the catalytic efficiency, increasing the refractive index and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of its preparation method of silicone oil for LED encapsulation, comprises the following steps:

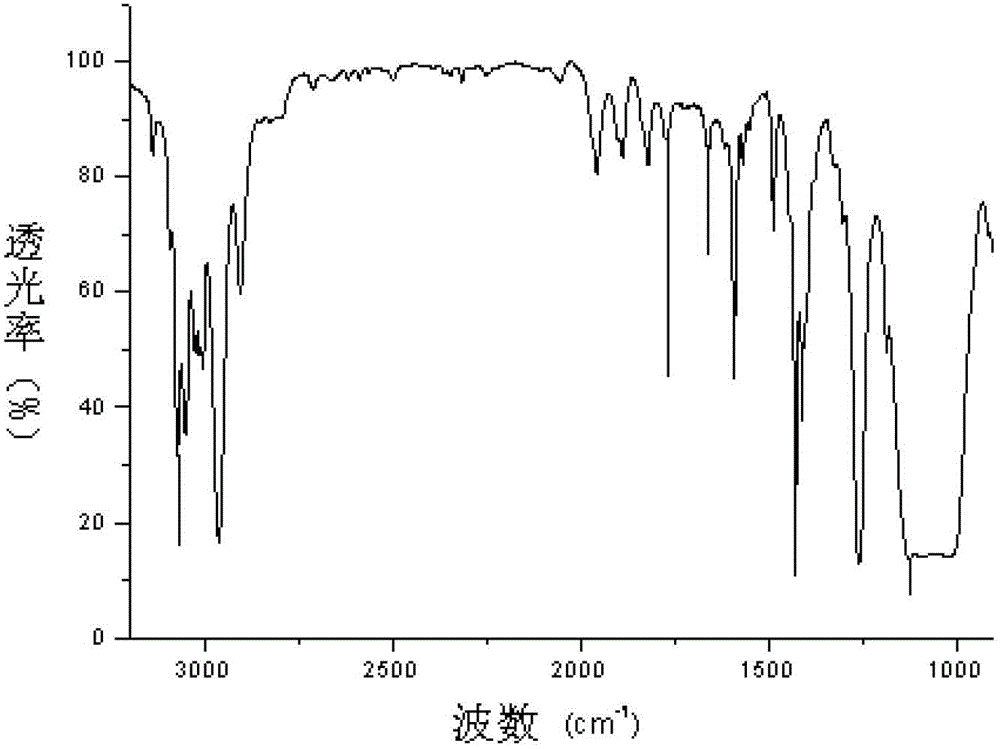

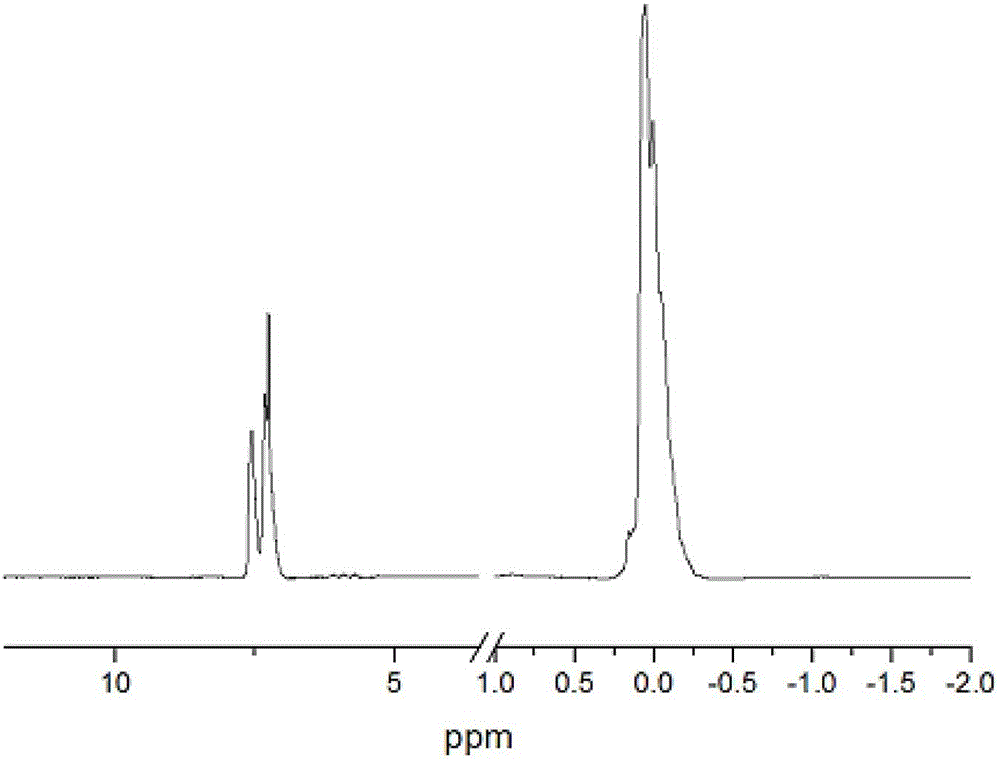

[0025] Mix methylcyclosiloxane, phenylcyclosiloxane, catalyst, end-capping agent and accelerator to obtain a mixed solution, carry out ring-opening polymerization and purification, and obtain silicone oil for LED packaging; the accelerator is two One or more of methyl sulfoxide, N,N-dimethylformamide, hexamethylphosphoric triamide, acetonitrile, nitrobenzene and butanone.

[0026] In the present invention, firstly, the methyl cyclosiloxane, the phenyl cyclosiloxane, the catalyst, the capping agent and the accelerator are mixed to obtain a mixed liquid, and the ring-opening polymerization reaction is carried out to obtain the mixed liquid containing the silicone oil for LED encapsulation.

[0027] In the present invention, the methylcyclosiloxane is preferably a mixture of decamethylcyclopentasiloxane, octamethylcyclotetrasiloxane, hexamethylcyc...

Embodiment 1

[0048] Add 50g octamethylcyclotetrasiloxane, 50g octaphenylcyclotetrasiloxane, 5g tetramethylammonium hydroxide and 10ml Dimethyl sulfoxide, after reacting at 100°C for 5h, then add 1.5g of 1,4-divinyltetramethyldisiloxane into the four-necked flask, and continue to react at 100°C for 2h to obtain Mixed liquid of silicone oil;

[0049] heating the mixed liquid containing silicone oil for LED packaging to 160°C, keeping it for 1 hour, decomposing the tetramethylammonium hydroxide, and obtaining a mixed liquid of silicone oil for LED packaging that does not contain a catalyst;

[0050] The mixed solution formed by 50mL of toluene and 100mL of methanol is used as the washing liquid, mixed with the mixed liquid of the silicone oil for LED packaging that does not contain the catalyst, placed in a separatory funnel, left to stand, and the lower layer of liquid is taken, and the lower layer of liquid is filtered , heated to remove a small amount of detergent in the lower liquid, and...

Embodiment 2

[0056] Add 50g octamethylcyclotetrasiloxane, 90g octaphenylcyclotetrasiloxane, 5g tetramethylammonium hydroxide and 15ml Dimethyl sulfoxide, after reacting at 100°C for 6h, then add 1.5g of 1,4-divinyltetramethyldisiloxane into the four-necked flask, and continue to react at 100°C for 2h to obtain Mixed liquid of silicone oil;

[0057] heating the mixed liquid containing silicone oil for LED packaging to 160°C, keeping it for 1 hour, decomposing the tetramethylammonium hydroxide, and obtaining a mixed liquid of silicone oil for LED packaging that does not contain a catalyst;

[0058] The mixed solution formed by 50mL of toluene and 100mL of methanol is used as the washing liquid, mixed with the mixed liquid of the silicone oil for LED packaging that does not contain the catalyst, placed in a separatory funnel, left to stand, and the lower layer of liquid is taken, and the lower layer of liquid is filtered , heated to remove a small amount of detergent in the lower liquid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com