Microwave photocatalytic coupling type waste water degrading device with reinforced catalyst interception procedure

A waste water degradation device and catalyst technology, applied in the direction of light water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

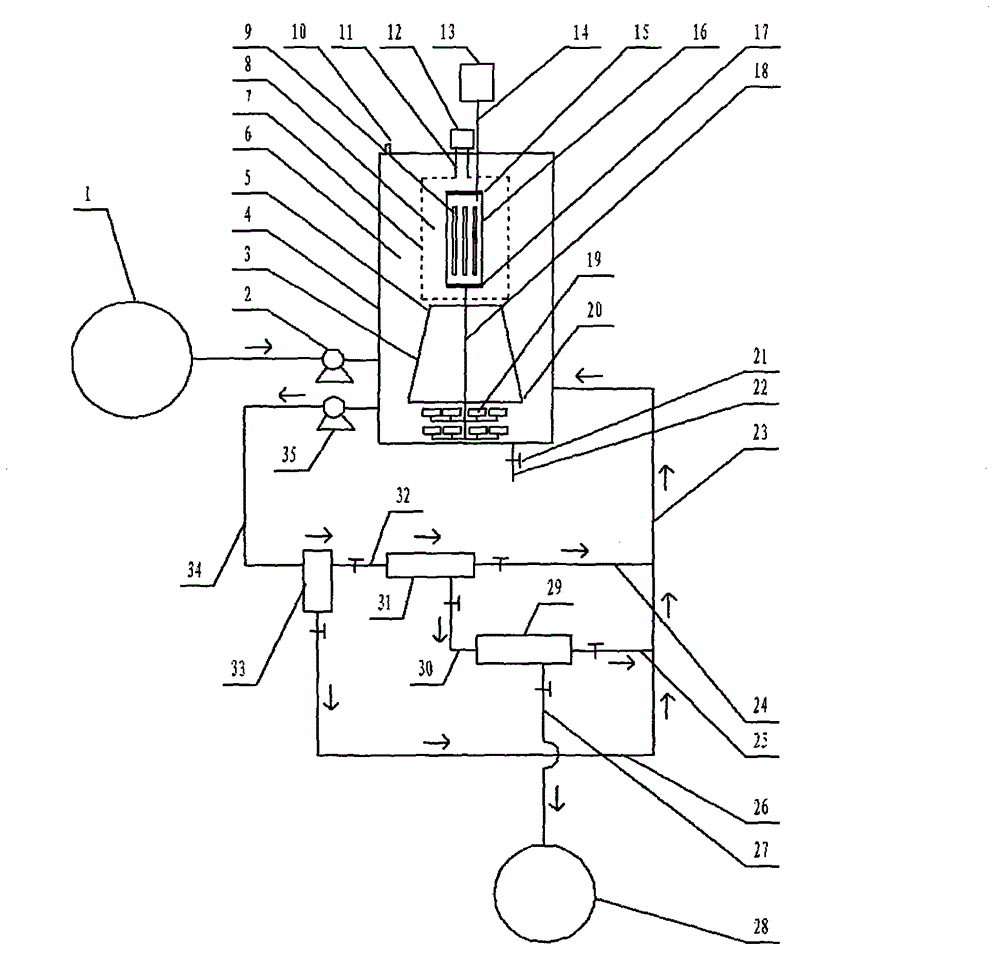

[0073] exist figure 1 In the shown embodiment of the present case, the structure of the device includes a reactor 4, which is a hollow container, and the outline of the reactor 4 is in the shape of a cube, a cuboid, a cylinder, an ellipse, or a polygonal prism. Body shape, spherical shape or ellipsoidal shape, many microporous aeration heads 19 are installed at the bottom position of this reactor 4 inner cavity, and, quartz tube 16, this quartz tube 16 is erected in the inside of described reactor 4 cavity position, the two ends of the quartz tube 16 are equipped with plugging caps 15, 17, and the two plugging caps 15, 17 respectively located at the two ends of the quartz tube 16 are provided with ventilation ports, and the electrodeless ultraviolet lamp 9 , the electrodeless ultraviolet lamp 9 is rod-shaped, ring-shaped, spherical, starfish-shaped or sea urchin-shaped, the number of the electrodeless ultraviolet lamp 9 is at least one, and the electrodeless ultraviolet lamp 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com