Composite electromagnetic-shielding copper clad laminate with heat conduction effect and manufacture method thereof

An electromagnetic shielding and copper foil substrate technology, which is applied to the flexible copper foil high thermal conductivity electromagnetic shielding substrate and its manufacturing field, can solve the problems of electromagnetic radiation and heat that cannot be effectively controlled, save production process, reduce product thickness, warp small curvature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

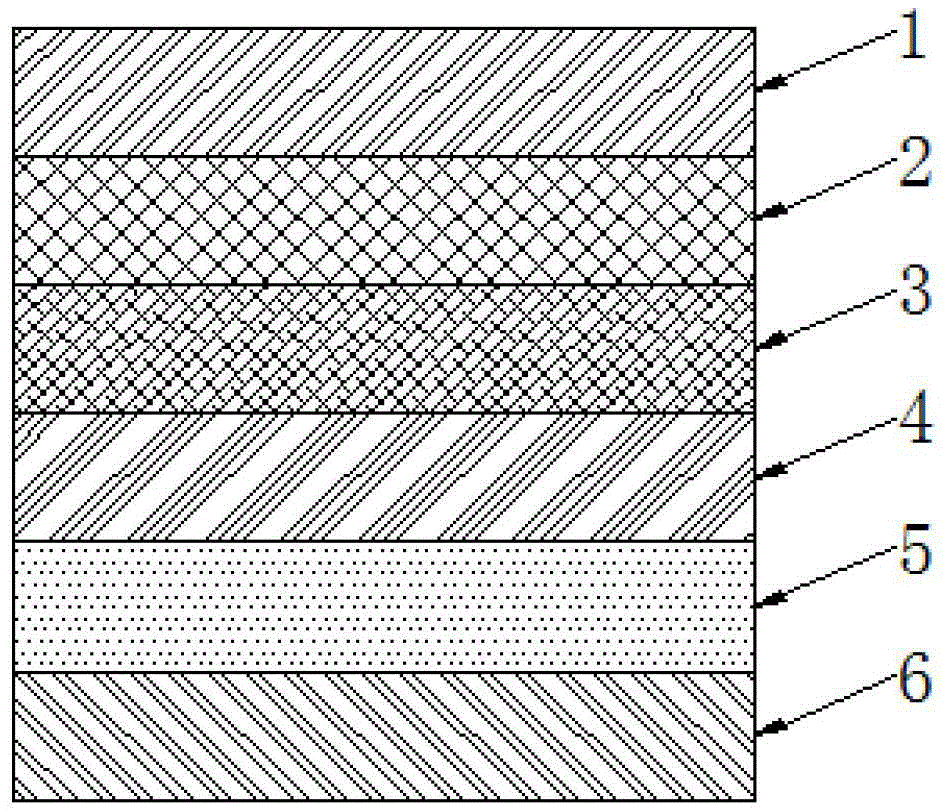

[0025] Embodiment: A composite electromagnetic shielding copper foil substrate with high thermal conductivity, such as figure 1 As shown, it consists of sequentially laminated copper foil layer 1, insulating polymer layer 2, heat dissipation adhesive layer 3, metal shielding layer 4, conductive adhesive layer 5 and laminated layer 6, which is a metal layer Or release material layer.

[0026] Wherein, the copper foil layer is rolled copper foil (RA copper), electrolytic copper foil (ED copper) or high ductility copper foil (HD copper), and the thickness of the copper foil layer is 7um~70um.

[0027] Wherein, the insulating polymer layer is an epoxy resin adhesive layer, an acrylate adhesive layer, a polyester adhesive layer, a polyurethane adhesive layer, a polyimide adhesive layer, a thermosetting polyimide (PI ) film, thermoplastic polyimide (TPI) film, polyester (PET) film, polynaphthyl ester (PEN) film and liquid crystal polymer (LCP) film, and the thickness of the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com