Preparation method of titanium foam used for cortical bone

A technology of foamed titanium and cortical bone, applied in the field of foamed titanium materials, can solve the problems of reducing the service life of titanium and titanium alloy implant materials, unfavorable bone tissue growth, and stress shielding, so as to avoid stress shielding and achieve long-term fixation , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

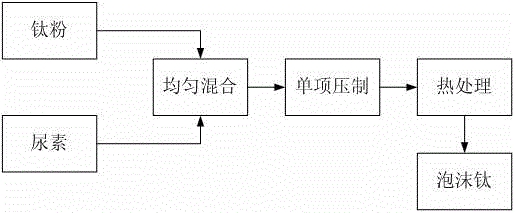

[0029] Example 1: see figure 2 , a method for preparing titanium foam for cortical bone, comprising the steps of:

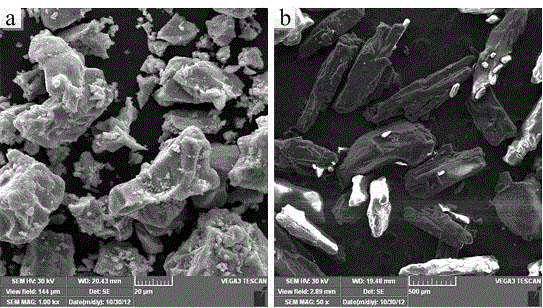

[0030] 1) Mixing of raw materials: select titanium powder and needle-shaped crystal urea particles with a particle size of 225-420 μm to grind and mix to obtain a preliminary mixture, wherein the mass-number ratio of titanium powder and pore-forming agent is 69.3:30.7; titanium powder and the microscopic morphology of urea particles as figure 1 shown. The titanium powder can be purchased directly from the market, and its surface and irregular shape can improve the strength of the green compact on the one hand and facilitate sintering on the other hand.

[0031] 2) The preliminary mixture is unidirectionally pressed into a green compact using a 600KN universal material testing machine, and the green compact is pressed into a cylindrical shape, wherein the unidirectional pressure is 200MPa, and the holding time is 1min; the green compact is sintered befor...

Embodiment 2

[0037] Example 2: A method for preparing foamed titanium for cortical bone, comprising the steps of:

[0038] 1) Mixing of raw materials: select titanium powder and urea to mix in the research body to obtain a preliminary mixture, in which titanium powder and pore-forming agent are used

[0039] The volume ratio is 67.2:32.8;

[0040] 2) The preliminary mixture is unidirectionally pressed into a green compact using a 600KN universal material testing machine, and the green compact is pressed into a cylindrical shape, wherein the unidirectional pressure is 150MPa, and the holding time is 1min;

[0041] 3) The green compact is placed in a vacuum carbon tube furnace, sintered at 1200° C. for 2 hours to remove the pore-forming agent, and finally cooled with the furnace to obtain titanium foam.

[0042] The porosity of the titanium foam prepared in Example 2 was 57.2%, and its compressive strength and Young's modulus were 126.3 MPa and 3.6 GPa, respectively.

Embodiment 3

[0043] Example 3: A method for preparing foamed titanium for cortical bone, comprising the steps of:

[0044] 1) Mixing of raw materials: select titanium powder and urea to mix in the research body to obtain a preliminary mixture, in which titanium powder and pore-forming agent are used

[0045] The quantity ratio is 70.8:29.2;

[0046] 2) The preliminary mixture is unidirectionally pressed into a green compact using a 600KN universal material testing machine, and the green compact is pressed into a cylindrical shape, wherein the unidirectional pressure is 250MPa, and the holding time is 1min;

[0047] 3) Put the green compact in a vacuum carbon tube furnace, remove the pore-forming agent and sinter at 1300° C. for 2 hours, and finally cool down with the furnace to obtain titanium foam.

[0048] The porosity of the titanium foam prepared in Example 3 is 55.9%, and its compressive strength and Young's modulus are 125.8MPa and 4.1GPa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com