Sheeted polyvinyl chloride (PVC) flooring with arc angles, production process for same and special die

A production process and arc angle technology, which can be used in buildings, building structures, floors, etc., can solve the problems of only two years, the change of internal stress cannot be eliminated, the floor is easy to warp, etc., to improve wear resistance, use Long life and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

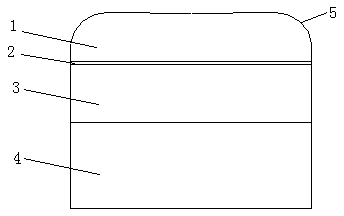

[0047] A production process for arc-angle sheet PVC flooring, as follows:

[0048] Step 1: Preparation of PVC wear-resistant layer, printed pattern layer, middle material layer and bottom material layer

[0049] 1. The preparation method of the middle material layer is:

[0050] (1) Mix the raw materials, that is, put 35 parts of polyvinyl chloride powder (that is, PVC powder), 18 parts of diisononyl phthalate, and 3 parts of zinc stearate into a high-speed mixer and stir for 4 minutes to obtain a mixed powder ;

[0051] (2) Internal mixing with internal mixer, that is, the mixed powder, 42 parts of calcium carbonate, 1 part of rosin, and 1 part of carbon black are sequentially put into the internal mixer for internal mixing, using the high temperature and high pressure functions of the internal mixer for internal mixing, so The raw materials are kneaded for 3 minutes and the temperature reaches 150°C, and then they are unloaded for the next production process;

[0052] (3)...

Embodiment 2

[0070] In this embodiment, the thickness of the PVC wear-resistant layer reaches 1.0mm, and the upper edge of the four sides of the PVC wear-resistant layer is guided and milled to have an outwardly convex arc angle of R0.9 (that is, the radius of the circle where the arc angle is located is 0.9mm).

[0071] The preparation method of material layer and bottom material layer in the present embodiment is identical with embodiment 1, and the content of calcium carbonate is 38% in the middle material layer, and the content of calcium carbonate in the bottom material layer is 32%.

[0072] In this embodiment, the PVC wear-resistant layer and the printed pattern layer are self-manufactured, and the manufacturing method belongs to the prior art in the industry, and will not be described in detail here.

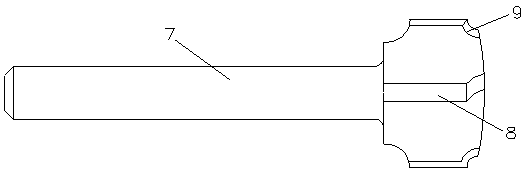

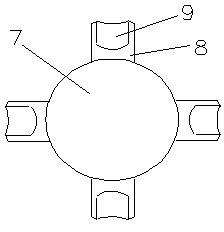

[0073] In this embodiment, the arc angle cutter used for lathe guide milling has an arc angle of R0.9 (that is, the radius of the circle where the arc angle is located is 0.9 mm).

...

Embodiment 3

[0076] In this embodiment, the thickness of the PVC wear-resistant layer reaches 1.5mm, and the upper edge of the four sides of the PVC wear-resistant layer is guided and milled to have an outwardly convex arc angle of R1.4 (that is, the radius of the circle where the arc angle is located is 1.4mm). Others are the same as in Example 1.

[0077] In this embodiment, since the thickness of the wear-resistant layer reaches 1.5mm, and its upper edge has a guide milling arc angle, this embodiment not only has excellent wear resistance, but also the arc angle of the wear-resistant layer can be permanently maintained, so the product's Longer service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com