Zinc vanadate nanorod composite paint

A technology of composite coatings and nanorods, applied in the direction of coatings, etc., to achieve the effects of non-toxic cost, good stability, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

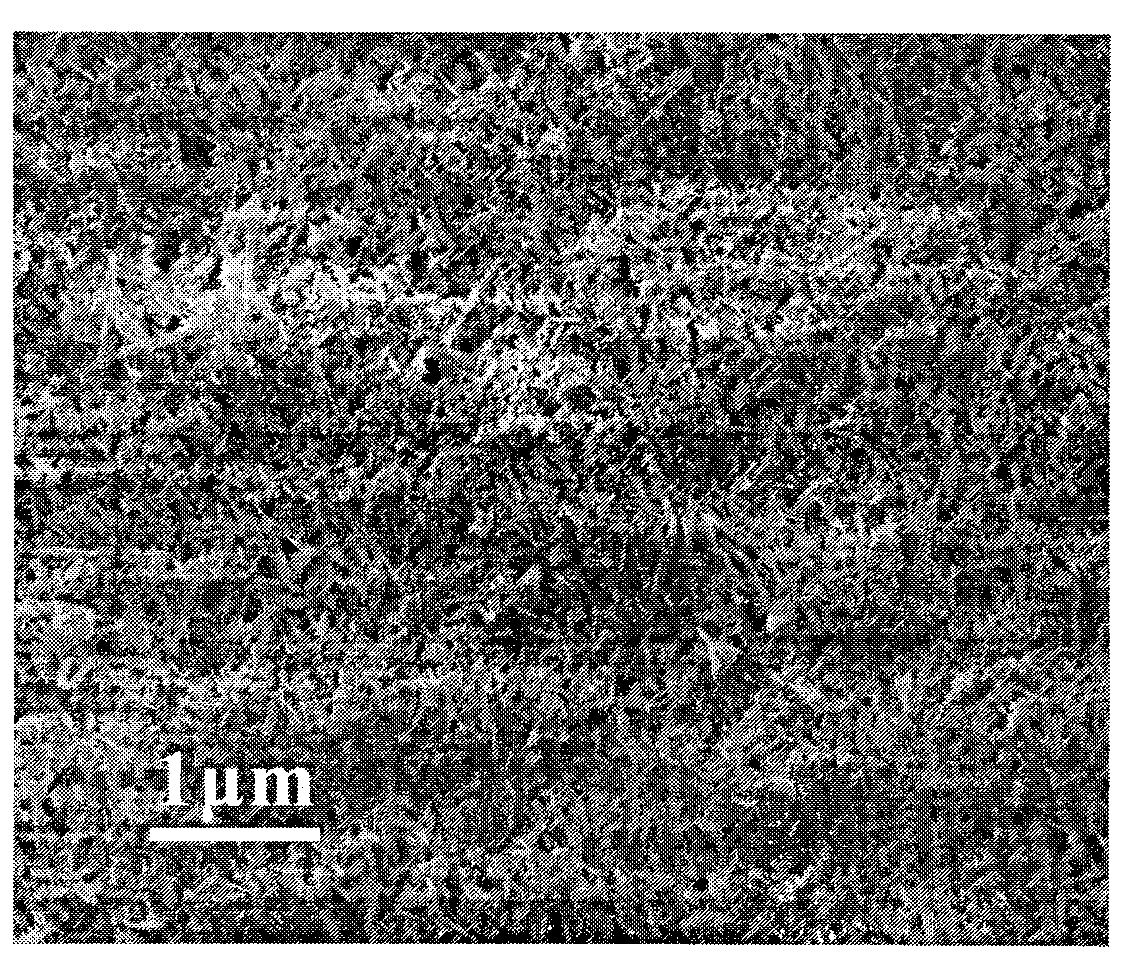

Image

Examples

Embodiment 1

[0020] Embodiment 1: determine that the mass percent of zinc vanadate nanorod composite paint is composed as follows: zinc vanadate nanorod 34%, styrene-acrylic emulsion 18.9%, water 35%, nano-alumina 10%, alcohol ester-12 0.1%, polyurethane 0.5%, 10% sodium hexametaphosphate aqueous solution 0.5%, tributyl phosphate 0.5%, ethylene glycol 0.5%.

Embodiment 2

[0021] Embodiment 2: determine that the mass percent of zinc vanadate nanorod composite paint is composed as follows: zinc vanadate nanorod 39%, styrene-acrylic emulsion 21.05%, water 30%, nano-alumina 8%, alcohol ester-12 0.1%, polyurethane 0.5%, 10% sodium hexametaphosphate aqueous solution 0.6%, tributyl phosphate 0.6%, ethylene glycol 0.6%.

Embodiment 3

[0022] Embodiment 3: determine that the mass percent of zinc vanadate nanorod composite paint is composed as follows: zinc vanadate nanorod 36%, styrene-acrylic emulsion 16.9%, water 33%, nano-alumina 12%, alcohol ester-12 0.1%, polyurethane 0.5%, 10% sodium hexametaphosphate aqueous solution 0.5%, tributyl phosphate 0.5%, ethylene glycol 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com