Method for continuous production of paranitroaniline by series-connected kettles

A technology of p-nitroaniline and kettle type, which is applied in the field of continuous production of p-nitroaniline in series kettle type and continuous ammonolysis unit reaction of fine chemical industry, which can solve potential safety hazards, high energy consumption, and difficult control of reaction temperature and pressure. Yield To achieve the effect of increasing the reaction speed, increasing the stirring speed, and increasing the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

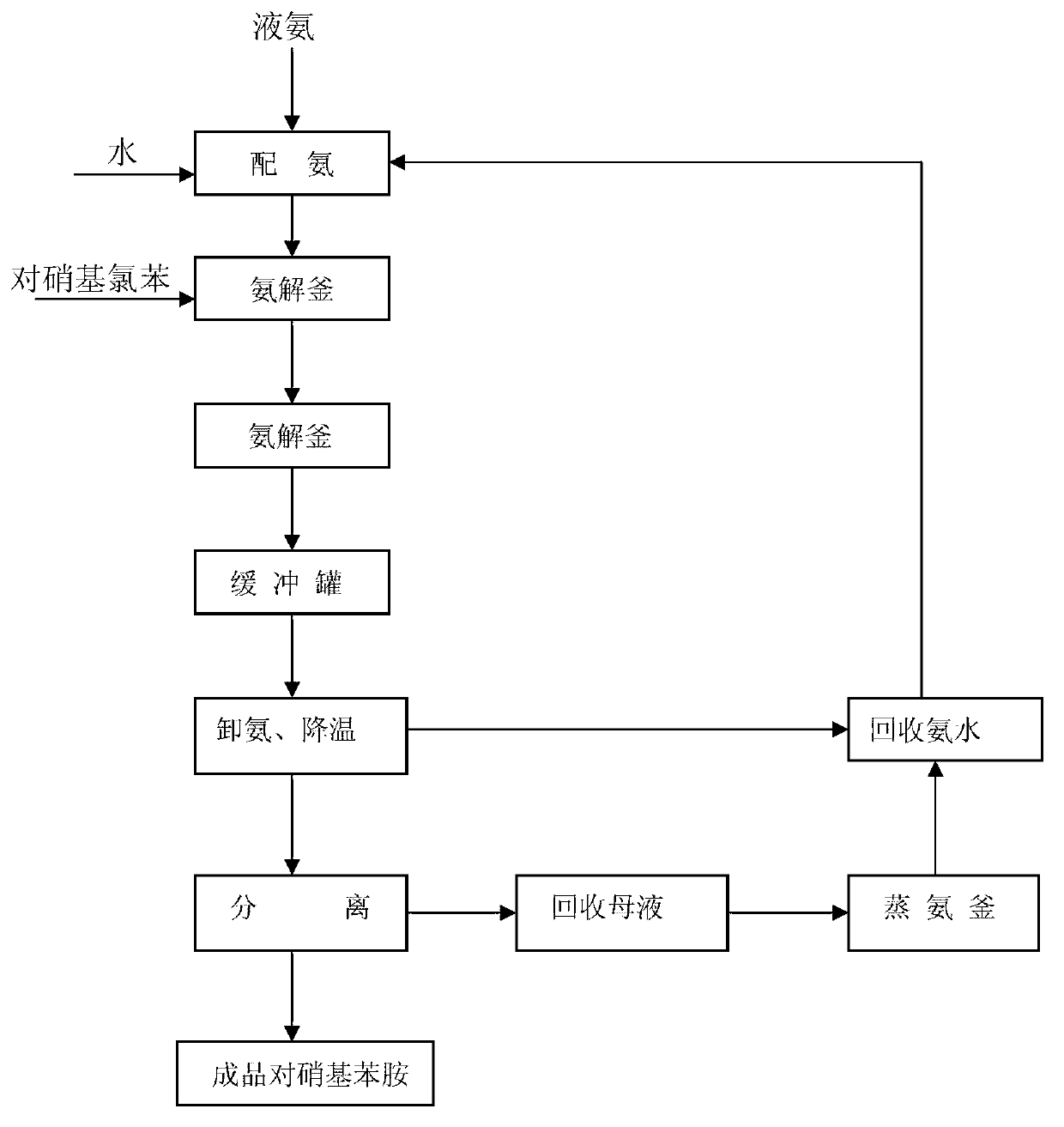

[0025] A method for continuous production of p-nitroaniline in series tank formula, comprising the following steps:

[0026] (1) Use liquid ammonia and water to prepare ammonia water with a mass percentage concentration of 40% in the ammonia water preparation tank, and transfer it to the ammonia water storage tank;

[0027] (2) Connect four high-pressure ammonolysis kettles in series through pipelines, each of which has a volume of 0.5m 3 ;

[0028] (3) Add ammonia water with a mass percentage concentration of 40% configured in step (1) into four high-pressure ammonolysis kettles connected in series, so that when the ammonia water in each high-pressure ammonolysis kettle reaches 50% of the kettle volume, stop feed;

[0029] (4) Slowly start the stirring, and adjust the stirring speed through the frequency regulator installed on the stirring motor of each high-pressure ammonialysis kettle, so that it gradually increases from 5 rpm to 300 rpm. At this time, the four high-press...

Embodiment example 2

[0034] (1) Use liquid ammonia and water in the ammonia water preparation tank to configure the ammonia water with a mass percentage concentration of 40%, and transfer it to the ammonia water storage tank;

[0035] (2) Three high-pressure ammonolysis kettles are connected in series through pipelines, each of which has a volume of 10m 3 ;

[0036] (3) Add ammonia water with a mass percentage concentration of 37% configured in step (1) into three high-pressure ammonolysis kettles connected in series, so that when the ammonia water in each high-pressure ammonolysis kettle reaches 50% of the kettle volume, stop feed;

[0037] (4) Slowly start the stirring, and adjust the stirring speed through the frequency regulator installed on the stirring motor of each high-pressure ammonialysis kettle, so that it can gradually increase to 400 rpm. Ammonolysis reaction is carried out for the materials in the tank. When the temperature reaches 180°C and the pressure reaches 6.1MPa, p-nitrochloro...

Embodiment 2

[0040] Obtain 2253kg of p-nitroaniline per hour in Example 2, the appearance of the product is yellowish brown, the chromatographic analysis content is 99.77%, and the yield is 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com