Ferroelectric thin film and film capacitor using the ferroelectric thin film

A technology for ferroelectric films and capacitors, applied in the field of ferroelectric films and film capacitors, can solve the problems of insufficient influence of the film structure, and achieve the effect of improving the reliability of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12、 comparative example 1~7

[0035] First, lead acetate was prepared as a Pb raw material, lanthanum acetate as a La raw material, tetra-n-butoxyzirconium as a Zr raw material, tetraisopropoxytitanium as a Ti raw material, and tetraethoxysilane as a Si raw material. In addition, 1-butanol was used as a solvent. Then, the PZT sol-gel solution with the metal composition ratio adjusted to Pb:Zr:Ti=110:52:48 and the PZT sol-gel liquid with the metal composition ratio adjusted to Pb:La:Zr:Ti=110:3:52:48 were synthesized, respectively. PLZT sol-gel solution, and a sol-gel solution doped with Si in PZT adjusted to Pb:Zr:Ti:Si=110:52:48:0.5-5. In addition, 2-ethylhexanoic acid and dimethyl succinate were prepared as organic substances and added to the PZT sol-gel solution at a constant ratio.

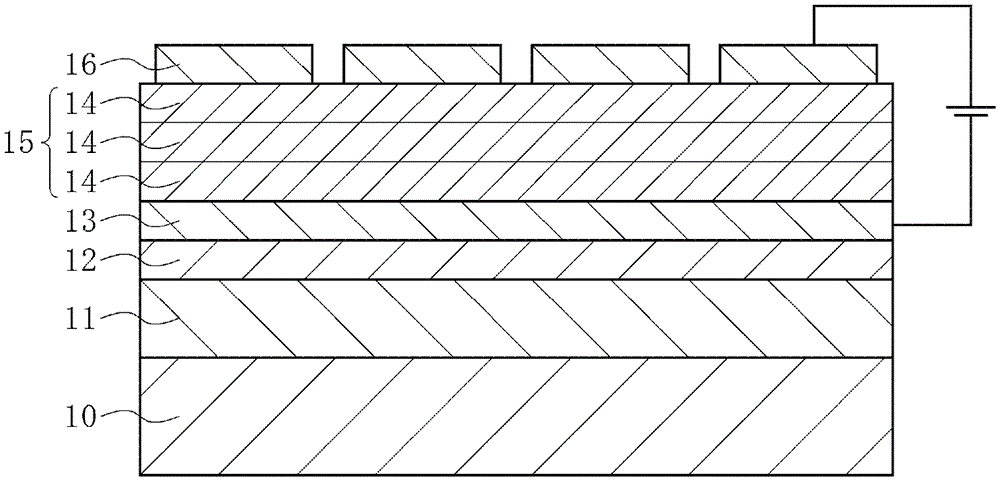

[0036] Next, a metal-insulator-metal (MIM, metal-insulator-metal) film capacitor was fabricated on a silicon substrate by the CSD method using the sol-gel solution synthesized above.

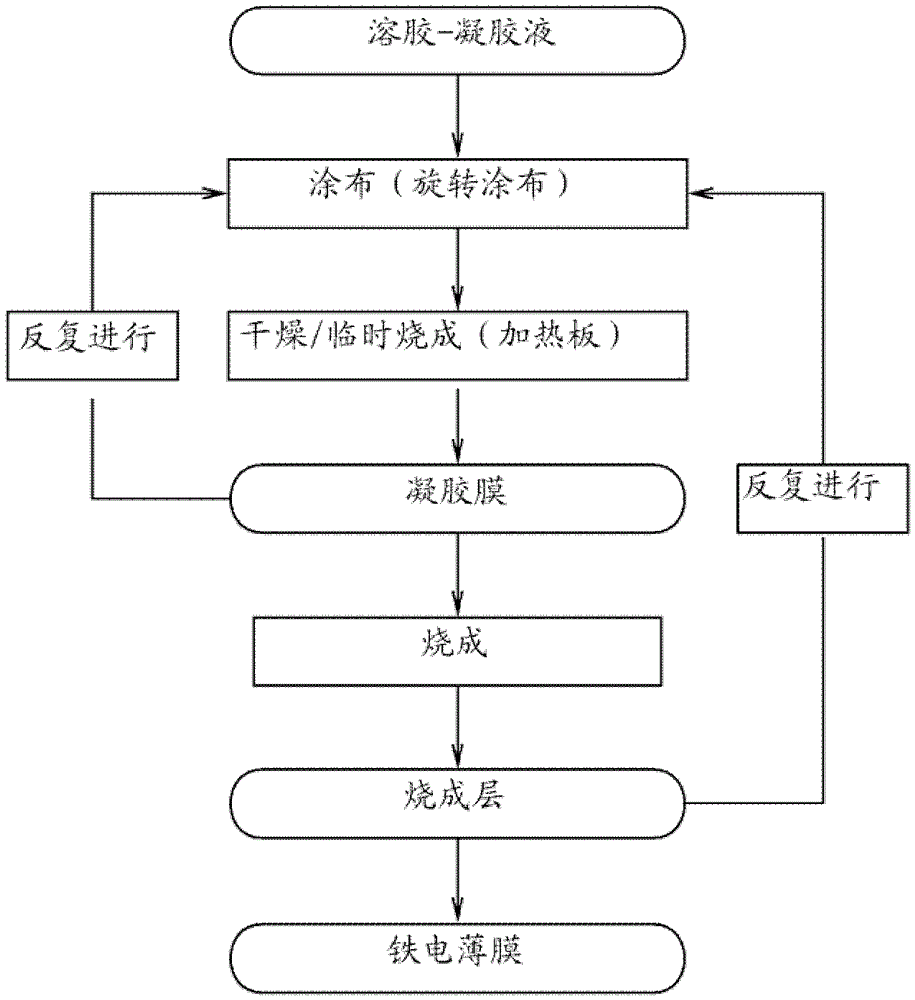

[0037] Specifically, as figure 1 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com