Photovoltaic capacitor and processing process thereof

A processing technology and capacitor technology, applied in the field of capacitors, can solve the problems of harsh operating conditions of photovoltaic equipment, high operating frequency of photovoltaic capacitors, large ripples and harmonic currents, etc., to improve insulation and capacity stability, ensure stable and Accuracy and low inductance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

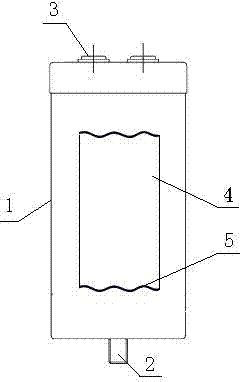

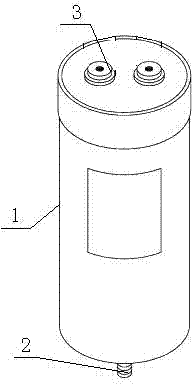

[0014] Volt capacitance of the present invention such as figure 1 and figure 2 As shown, the upper surface of the capacitor core 4 is provided with a coated plate, the lower surface of the capacitor core 4 is provided with a gold-sprayed plate, the capacitor core is installed in the shell 1, and the capacitor core 4 and the shell 1 are provided with Epoxy resin filling, the upper and lower ends of the capacitor core 4 are wave cut surfaces 5, the upper end of the housing 1 is provided with an upper terminal 3, the lower part of the housing 1 is provided with a lower terminal 2, an upper terminal 3 and a lower terminal 2 Connect the gold-sprayed plate of capacitor core 4.

[0015] The photovoltaic capacitor processing technology includes the following steps:

[0016] a. Slitting the capacitor core 4 by a wave slitting process;

[0017] b. The capacitor core 4 after cutting is put into the case 1 , and epoxy resin is filled between the case 1 and the capacitor core 4 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com