Silica aerogel material and preparation method thereof

A silica and aerogel technology, applied in the direction of silica, silica, chemical industry, etc., can solve the problem of reducing the brittleness of aerogel, reducing the effect of heat conduction and energy saving, not mentioning material density, thermal conductivity and hydrophobicity , flexibility, strength and other performance issues, to achieve the effect of easy industrial production, reduce material brittleness, and strengthen the connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

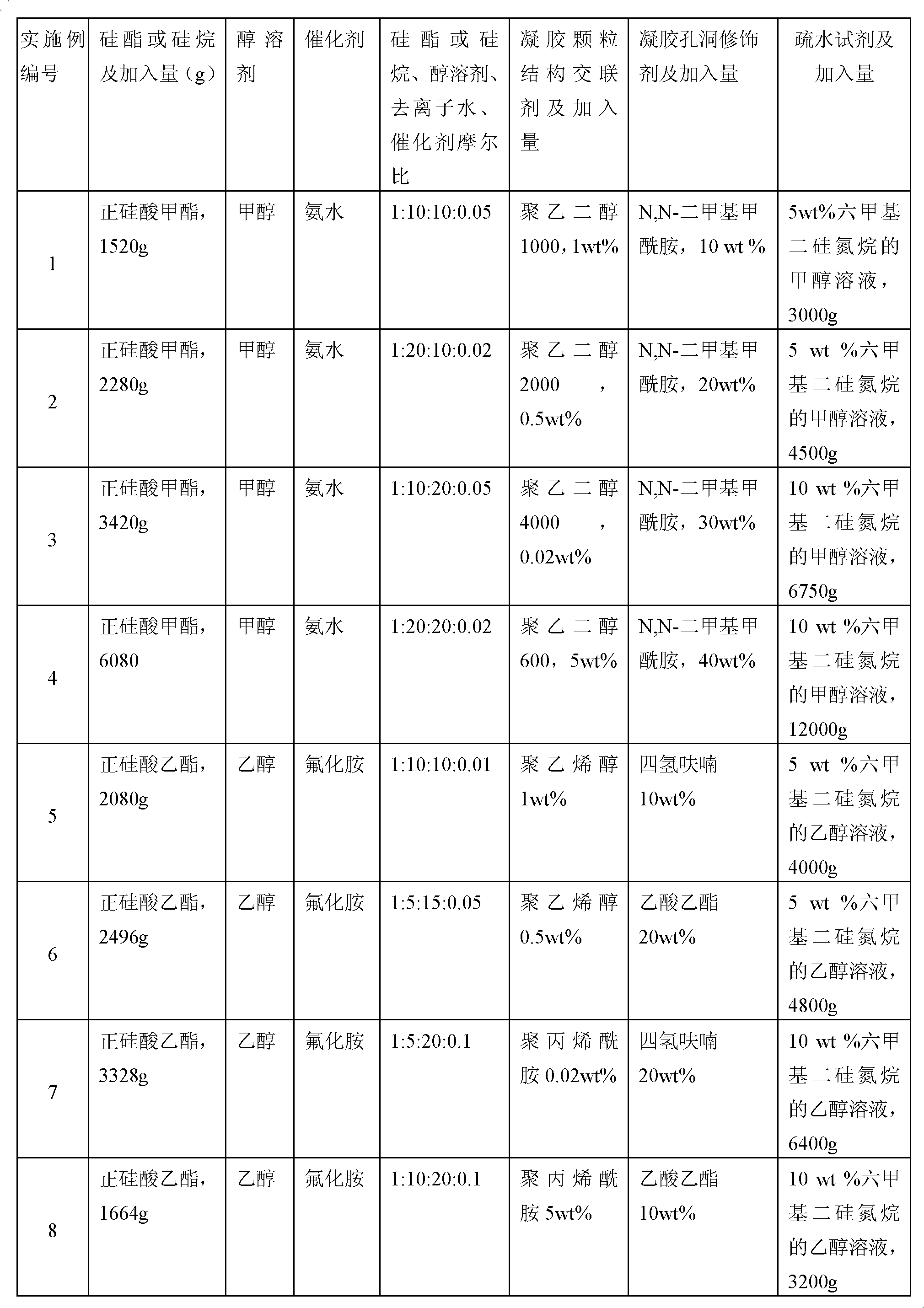

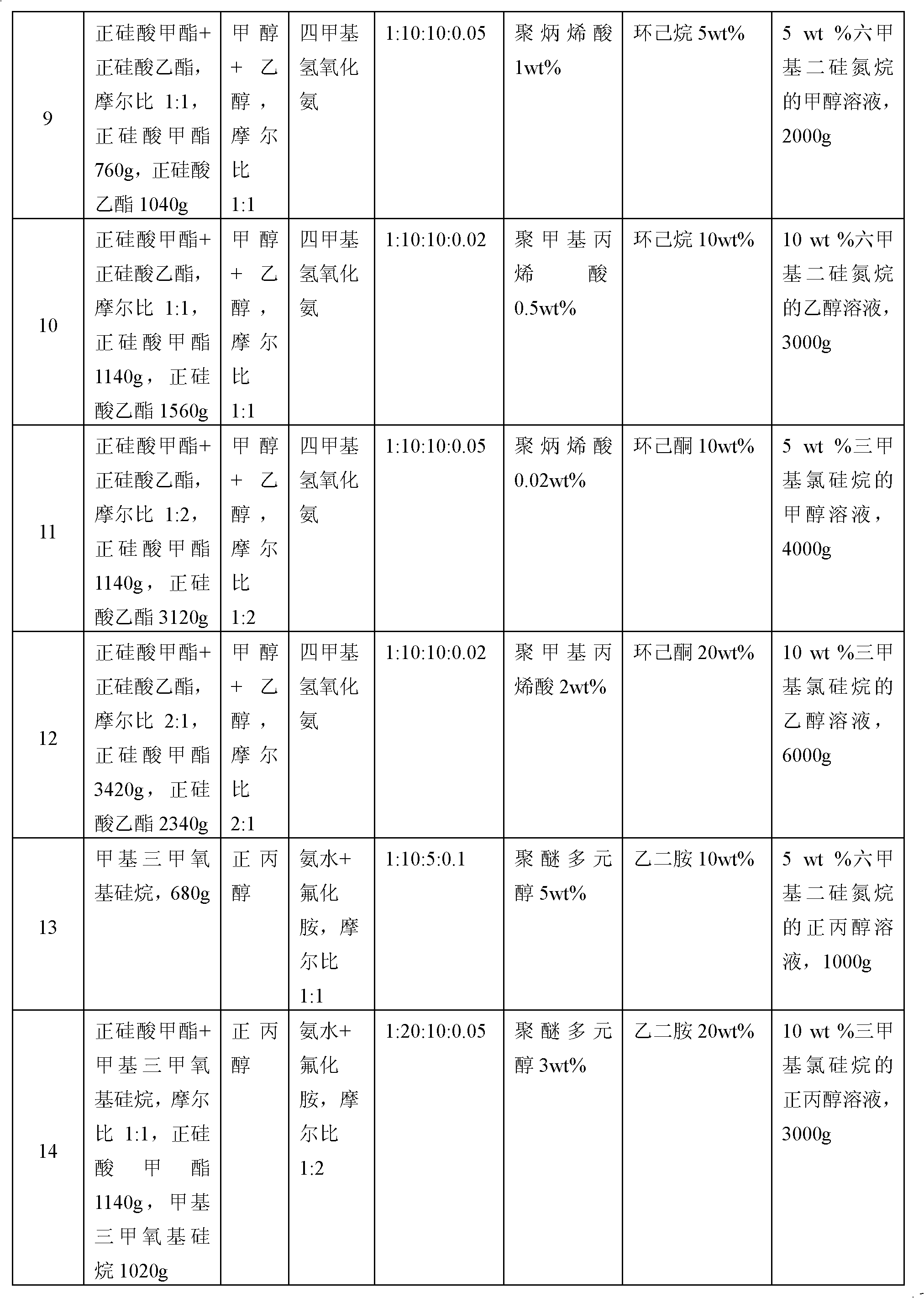

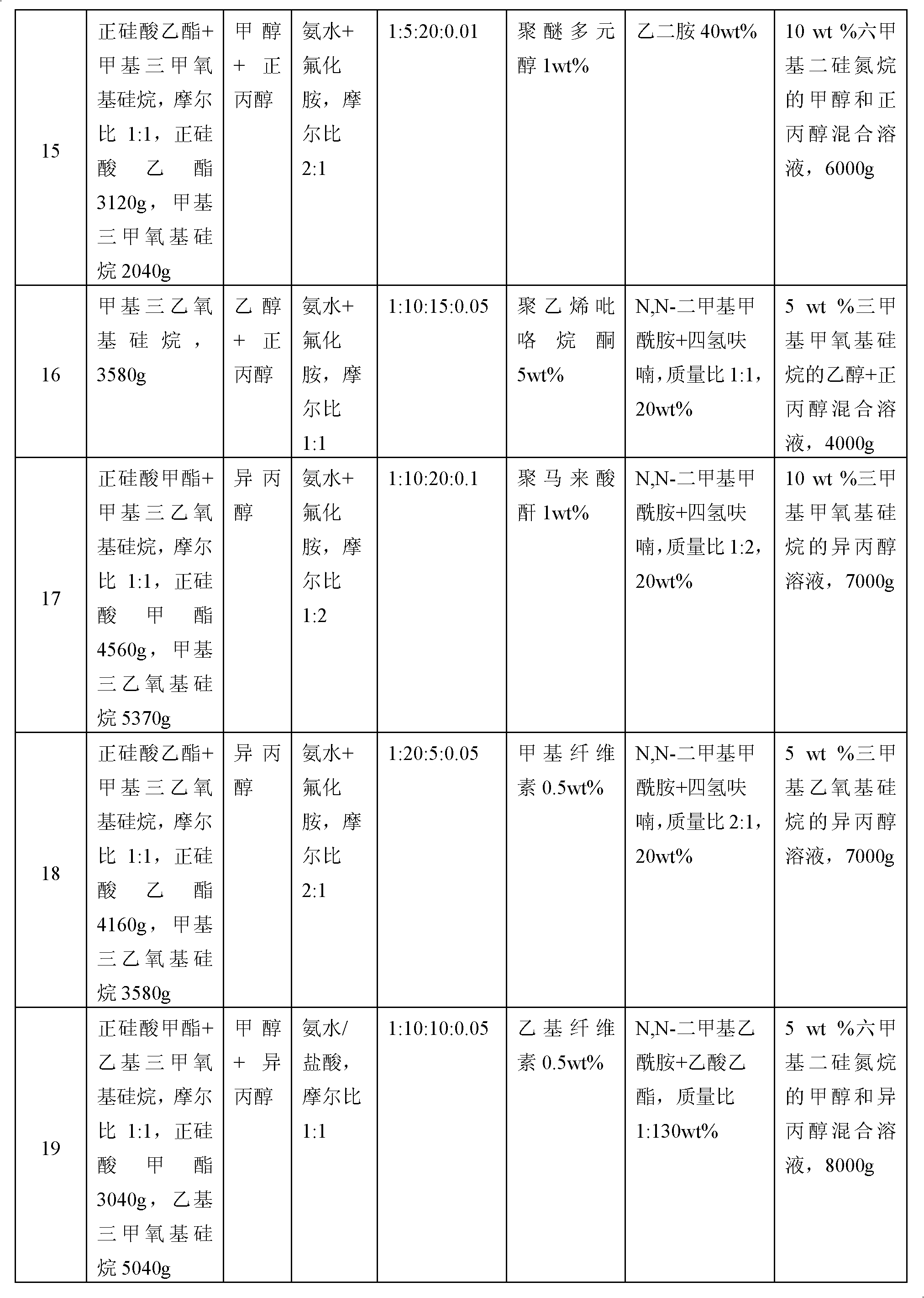

Examples

Embodiment 1

[0031] (1) Preparation of sol-gel: Take 1520g methyl orthosilicate, mix evenly with methyl orthosilicate, methanol, and deionized water in a molar ratio of 1:10:10, then gradually add methyl orthosilicate 1wt% polyethylene glycol 1000 of the total weight of methanol, deionized water as the gel particle structure crosslinking agent and 10wt% of the total weight of methyl orthosilicate, methanol, deionized water N, N-dimethyl Use methyl orthosilicate as a gel pore modifying agent, stir evenly, then add ammonia water according to the molar ratio of methyl orthosilicate and catalyst of 1:0.05 and stir evenly to obtain silica sol; then fill the silica sol into a flat mold of 400x400mm and seal it After standing at 20°C, a gel was formed after 2 hours.

[0032] (2) Gel aging, hydrophobization, and solvent replacement: Aging the gel prepared in step (1) at room temperature for 72 hours; adding 3000 g of hexamethyldisilazide with a mass percentage of 5 wt % to the flat mold The metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com