Method for preparing nanocrystalline low activation martensitic steels

A martensitic steel and nanocrystalline technology, applied in the field of structural steel materials, can solve the problems that have not yet been seen in nanocrystalline CLAM steel, and achieve the effect of fast method, smooth surface and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

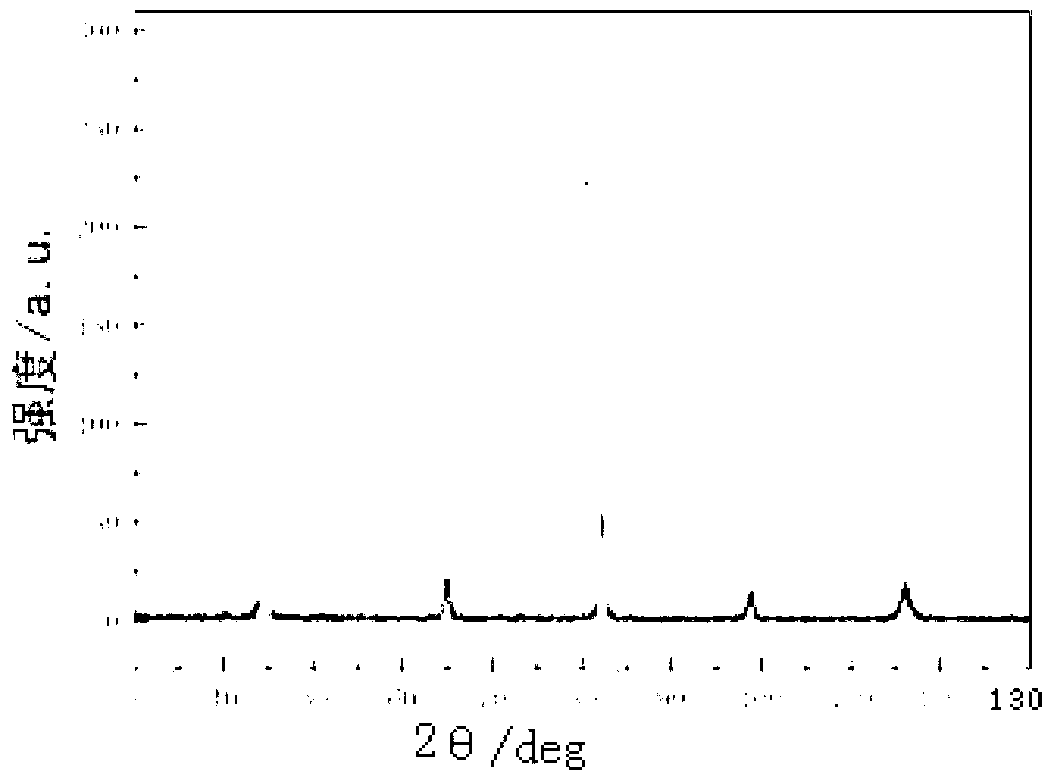

Image

Examples

Embodiment 1

[0016] 1) A 10 g CLAM steel sample was broken and ultrasonically cleaned with acetone and alcohol.

[0017] 2) Put the sample into the quartz tube. The bottom of the quartz tube is a round hole with a diameter of 1.0 mm. Then insert the quartz tube into the induction heating coil. The distance between the quartz tube and the copper roller is 2 mm.

[0018] 3) Vacuum the furnace body to 1.2×10 -4 Pa. Then fill the furnace with argon, and when the vacuum pressure in the furnace reaches -0.05 Pa, fill the argon pressure tank to 0.05 Pa, so that the pressure of the system is 1 atmosphere.

[0019] 4) Set the speed of the copper roller to 28 m / s, heat the sample, and set the melt blowing temperature to 1520 °C. Quickly press the jet button to get a nanocrystalline CLAM steel thin strip, the main phase is α-Fe, the thin strip is 1.2-2.7 mm wide, the thickness is 40 μm, and the grain size is 19.7 nm.

Embodiment 2

[0021] 1) 8 g of CLAM steel samples were broken and ultrasonically cleaned with acetone and alcohol.

[0022] 2) Put the sample into the quartz tube. The bottom of the quartz tube is a round hole with a diameter of 1.0 mm. Then insert the quartz tube into the induction heating coil. The distance between the quartz tube and the copper roller is 2 mm.

[0023] 3) Vacuum the system to 1.2×10 -4 Pa. Then fill the furnace with argon, and when the pressure in the furnace reaches -0.05 Pa, fill the argon pressure tank to 0.05 Pa, so that the pressure of the system is 1 atmosphere.

[0024] 4) Set the speed of the copper roller to 20 m / s, heat the sample, and set the melt blowing temperature to 1520 °C. Quickly press the air injection button to get a thin strip of nanocrystalline CLAM steel, the main phase is α-Fe, the thin strip is 1.1-3.1 mm wide, the thickness is 60 μm, and the grain size is 25.6 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com