Production method of carbon fiber cloth surface molecular imprinting passive sampling membrane for organic pollutants in water environment

A technology of surface molecular imprinting and organic pollutants, applied in the fields of carbon fiber, fiber processing, chemical instruments and methods, etc., can solve the problems of reduced precision and sampler failure, and achieve the effect of strong mechanical strength, fast method, and reduced interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

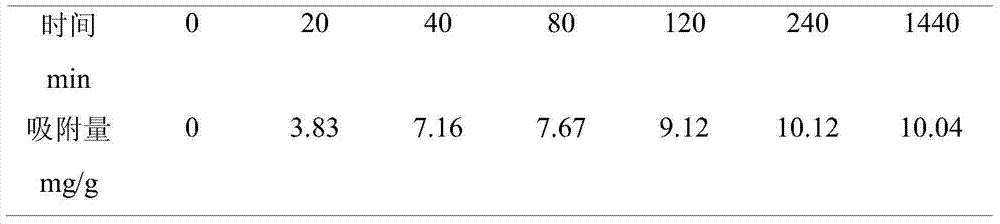

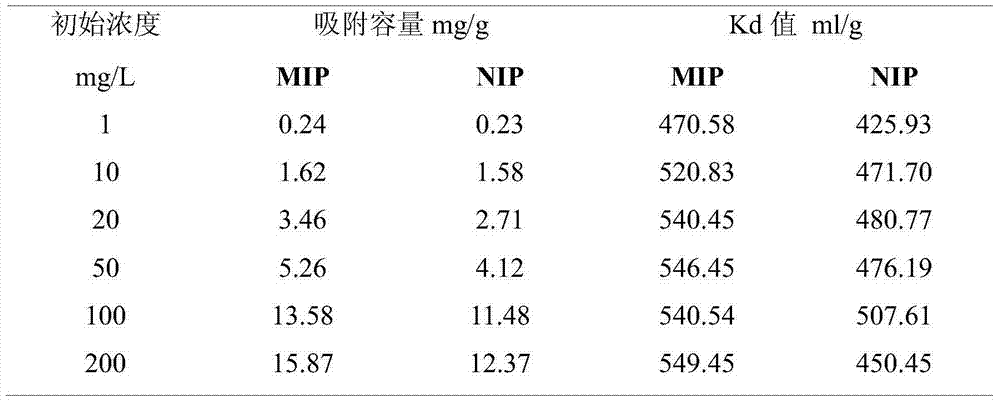

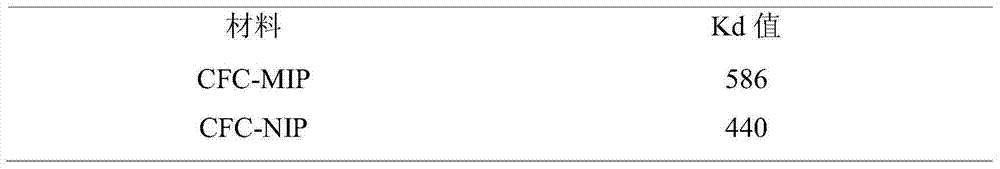

[0020] Take bisphenol A in water as an example

[0021] The specific steps of the preparation method of the carbon fiber cloth surface molecularly imprinted passive sampling membrane for organic pollutants in sewage according to the present invention are as follows:

[0022] Because the surface of carbon fiber cloth sold in the general market is coated with epoxy resin as the main component, we first removed the coating on the surface of the raw material before synthesis.

[0023] The removal method is as follows: take a piece of carbon fiber cloth (6cm in length and width) and put it in 120ml of 8M nitric acid, reflux at 90°C for 5 hours, wash it with acetone first, then wash it with distilled water, and put it in a vacuum after the end Dry in a drying oven at 60°C for 12 hours. Then silanize the surface, that is, graft KH-570 on the surface.

[0024] Grafting method: Take 120ml of ethanol aqueous solution with a volume ratio of 3:1, add a piece of carbon fiber cloth (about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com