Method for pouring bituminous mortar in deep slotted hole

An asphalt mortar and slot technology, which is used in dams, buildings, barrages, etc., can solve problems such as uneven technology, leakage between layers of asphalt concrete core walls, and difficulties, and achieve reliable remedial methods, quick repairs, and quick methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

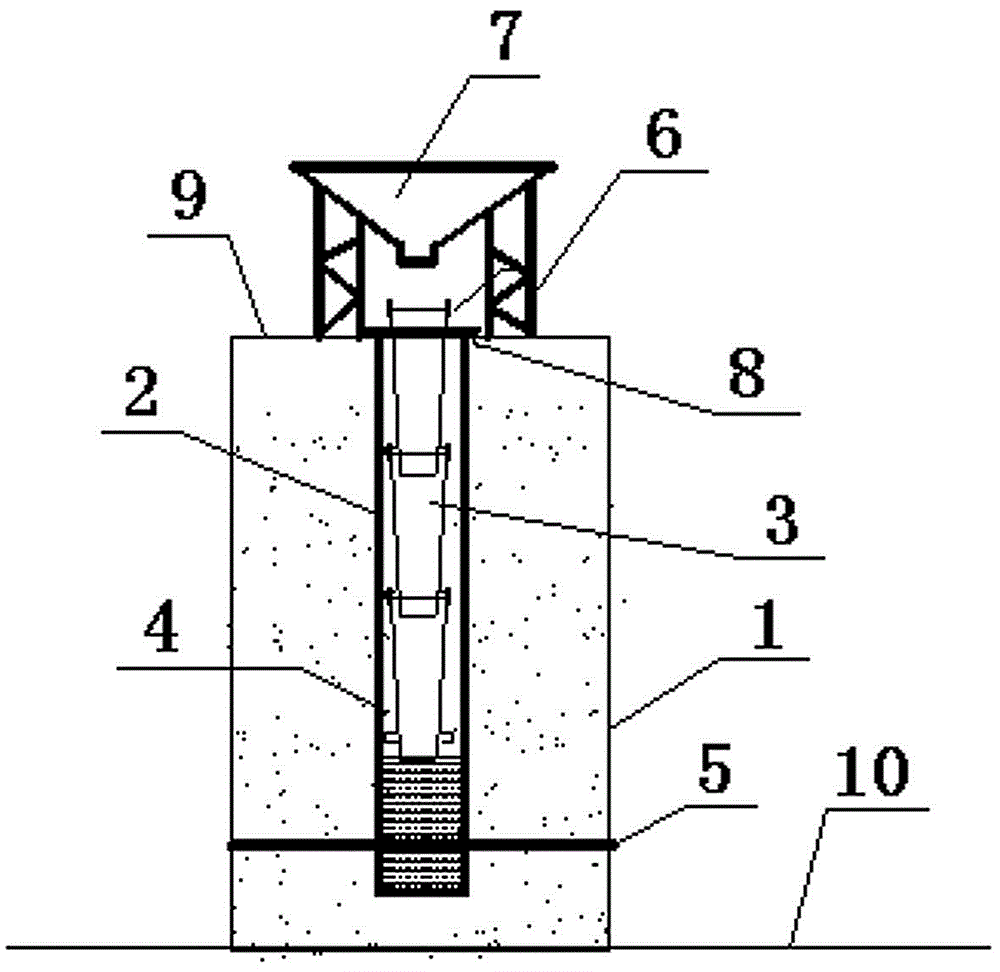

[0011] see figure 1 , the method for pouring asphalt mortar in the deep groove hole of the present embodiment comprises the following steps:

[0012] 1) Drill slot hole 2 on asphalt concrete core wall 1;

[0013] 2) Before pouring the asphalt mortar, clean up the sundries in the slot, and make the bottom of the slot and the wall of the slot clean and dry, and lower the chute 3 heated to 90°C to the bottom of the slot where the asphalt mortar is to be poured;

[0014] 3) Pouring asphalt mortar 4 upwards from the bottom of the slot hole. When pouring, first heat the part where the asphalt mortar will be poured and the area 40-50 cm above it. The heating temperature is 50°C, and then pour 150°C left and right asphalt mortar. The height of each pouring The ascent speed is 25cm / min; during pouring, there are measures to shield rainwater to prevent rainwater from entering the pouring hole; after pouring all the slot sections, the leaky asphalt concrete core wall is quickly repaired...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com