Phosphorous gettering method of metallurgy polycrystalline silicon wafer, silicon wafer and solar cell prepared by silicon wafer

A polysilicon wafer and phosphorus gettering technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of long battery production cycle, new dislocations in silicon wafers, and small phosphorus diffusion coefficient, so as to improve the photovoltaic Effects of conversion efficiency, improved lifetime, and shortened diffusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Metallurgical polycrystalline silicon wafers were selected, and the silicon wafers were prepared by the cold crucible technology jointly developed by Baotou Shansheng New Energy Company and the Institute of Semiconductors, Chinese Academy of Sciences, with an area of 156×156 mm2 and a thickness of 180±20 μm.

[0040] (1) Soak the metallurgical polysilicon wafer in hydrofluoric acid (48.5-49.5% by mass fraction) and nitric acid (65-68% by mass fraction) with a volume ratio of HF:HNO3:H2O=1:3:2 at room temperature. %) and deionized water for 15 seconds to remove the damage layer on the surface of the metallurgical polysilicon wafer;

[0041] (2) The rinsing method of soaking in circulating water is adopted, and the silicon wafer obtained in step (1) is rinsed once for 3 minutes using deionized water at room temperature, and then at 140° C. in the SG10C type silicon wafer rotary washing and drying machine (Wuxi City Aomante Technology Co., Ltd.) for 400 seconds of drying...

Embodiment 2

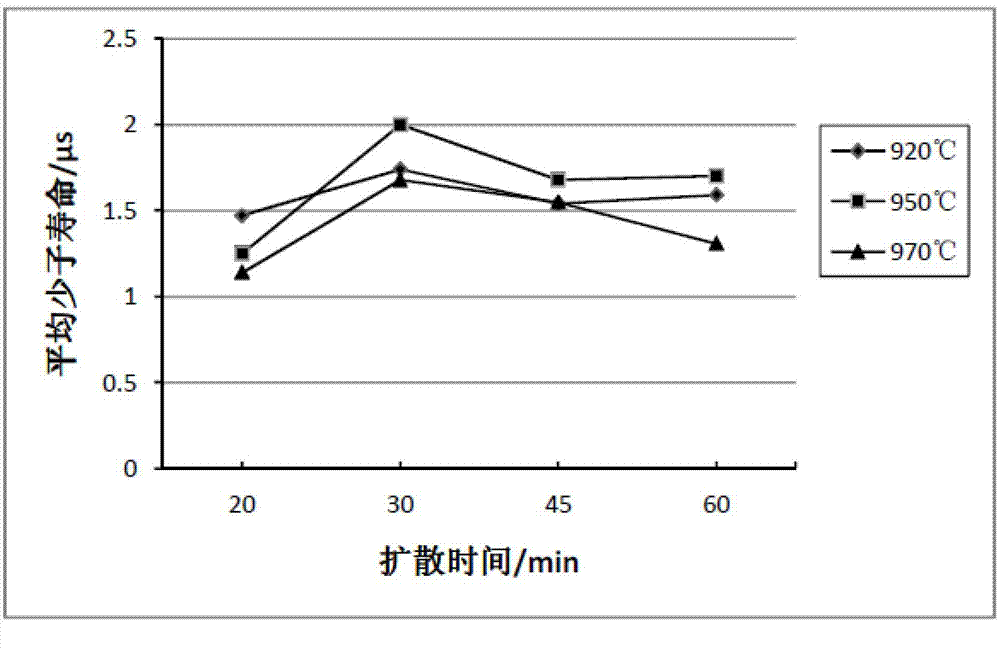

[0051] Same as Example 1, the difference is that the diffusion temperature in step (3) is 920°C.

[0052] Table 2 shows the average minority carrier lifetimes of silicon wafers obtained after phosphorus gettering with different diffusion times (20min, 30min, 45min, 60min) at a diffusion temperature of 920°C.

[0053] Table 2

[0054] Diffusion time

[0055] It can be seen from Table 2 that the average minority carrier lifetime can be increased from 0.8 μs to 1.54–1.74 μs after a short time of phosphorus diffusion and gettering for 30–45 min at a diffusion furnace temperature of 920 °C.

Embodiment 3

[0057] Same as Example 1, the difference is that the diffusion temperature in step (3) is 970°C.

[0058] Table 3 shows the average minority carrier lifetimes of silicon wafers obtained after phosphorus gettering with different diffusion times (20min, 30min, 45min, 60min) at a diffusion temperature of 920°C.

[0059] table 3

[0060] Diffusion time

20min

30min

45min

60min

average life expectancy

1.14μs

1.68μs

1.55μs

1.31μs

[0061] It can be seen from Table 3 that the average minority carrier lifetime can be increased from 0.8 μs to 1.55–1.68 μs after short-term phosphorus diffusion and gettering for 30–45 min at a diffusion temperature of 970 °C.

[0062] According to the test result of above-mentioned embodiment 1-3 and with reference to figure 1 It can be seen that, according to the method of the present invention, when the diffusion temperature is 950° C. and the diffusion time is 30 minutes, the average minority car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com