Forming method of semiconductor component

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve the problems of large RC effect and poor performance of semiconductor integrated circuits, and achieve the effects of improving performance, reducing RC effect, and avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

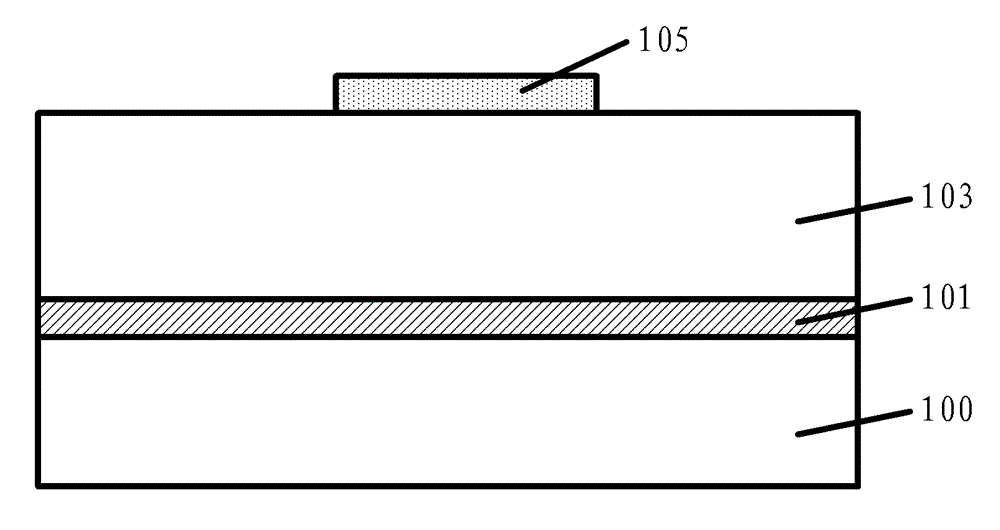

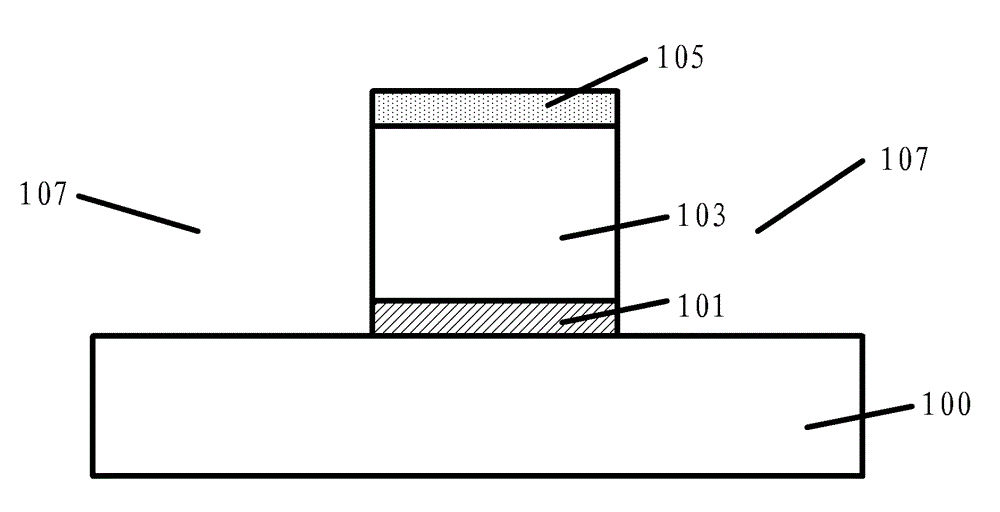

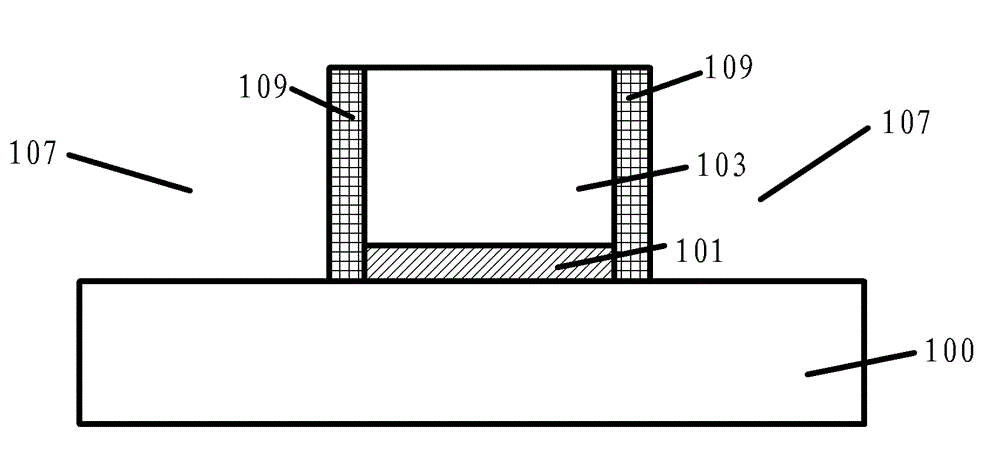

[0042] As mentioned in the background, the RC effect of the semiconductor device in the prior art is still relatively large, and the performance of the semiconductor integrated circuit is poor.

[0043] After research, the inventors found that in the prior art, when the opening is formed, if the size (width) of the opening is too large, the material used to form the insulating layer will fall into the opening when the insulating layer is subsequently formed, making it difficult to deposit the insulating layer. , it is difficult to form an insulating layer covering the metal line and across the opening, and even if the insulating layer is formed, the quality of the void gap is greatly affected. Therefore, limited by the subsequent deposition process, the size (width) of the air gap formed in the prior art is usually small, and the K value in the interconnection structure that can be reduced by the small air gap is relatively limited. The semiconductor device The RC effect is st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com