Semiconductor device and method of forming the same

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve the problems of large RC effect and poor performance of semiconductor integrated circuits, etc., and achieve the effects of improving performance, reducing RC effect, and solving deposition difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

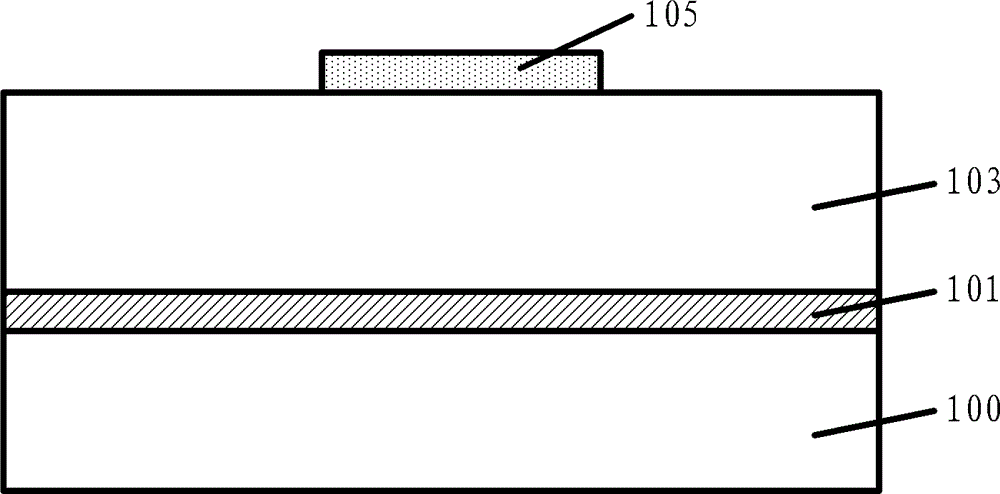

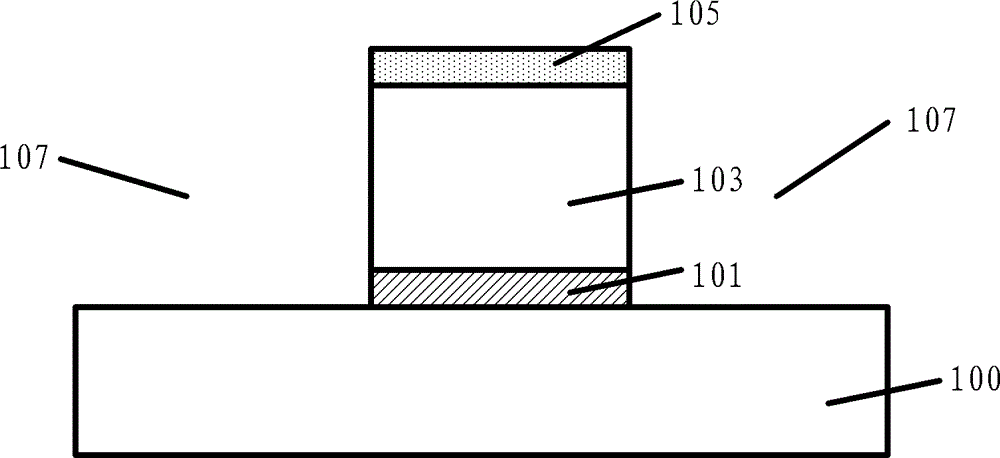

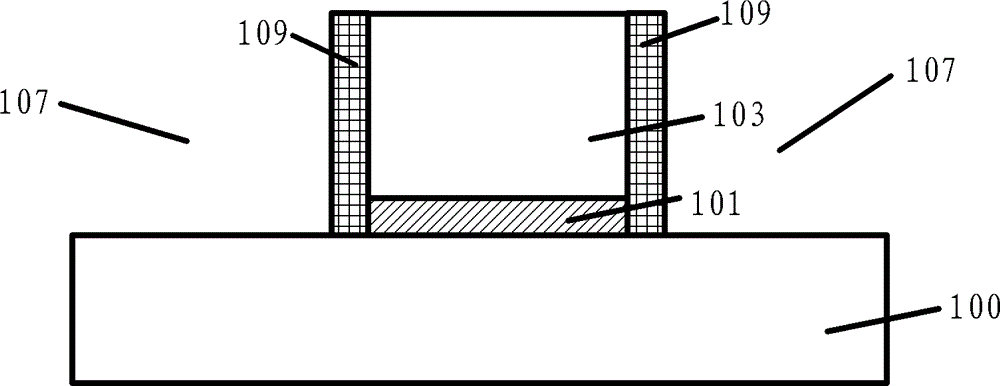

[0067] Please refer to Figure 8 , providing a substrate 300; an etch barrier layer 301 is formed on the surface of the base 300; a first insulating layer 303 is formed on the surface of the etch barrier layer 301; an interlayer dielectric layer 305 is formed on the surface of the first insulating layer 303; A buffer layer 307 is formed on the surface of the interlayer dielectric layer 305 ; a second mask layer 308 is formed on the surface of the buffer layer 307 .

[0068] Wherein, the substrate 300 is used to provide a working platform for subsequent processes, and the part of the substrate 300 in contact with the etching barrier layer is an insulating material. There may also be transistors and the like in the substrate 300 .

[0069] The etch stop layer 301 is used to subsequently protect the substrate 300 from being damaged when the trench 309 is formed, the material of the etch stop layer 301 is SiN or TiN, and the formation process of the etch stop layer 301 is a depos...

no. 2 example

[0116] Different from the first embodiment of the present invention, in the second embodiment of the present invention, at least three grooves need to be formed: a first groove, a second groove adjacent to the first groove, and a groove adjacent to the first groove. The third trench adjacent to the second trench and spaced apart from the first trench forms the first metal line layer, the second trench and the second trench respectively located in the first trench, the second trench and the third trench. The metal line layer and the third metal line layer; the first insulating layer and part of the interlayer dielectric layer between the first metal line layer and the second metal line layer are removed to form an opening, while the second metal line layer remains and the first insulating layer and the interlayer dielectric layer between the third metal line layer.

[0117] Please refer to Figure 15 , providing a substrate 400, an etch barrier layer 401 is formed on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com