Indium columns for face-down bonding interconnection of infrared focal plane and preparation method thereof

A technology of infrared focal plane and indium pillars, which is applied in the field of reverse soldering interconnection technology of infrared focal plane detectors, can solve problems such as the difficulty of evaporating indium to fill indium pillar holes, short circuit of pixels, and small bottom of indium pillars, etc., so as to avoid sticking The effect of binder residue, good height consistency, and large bottom size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

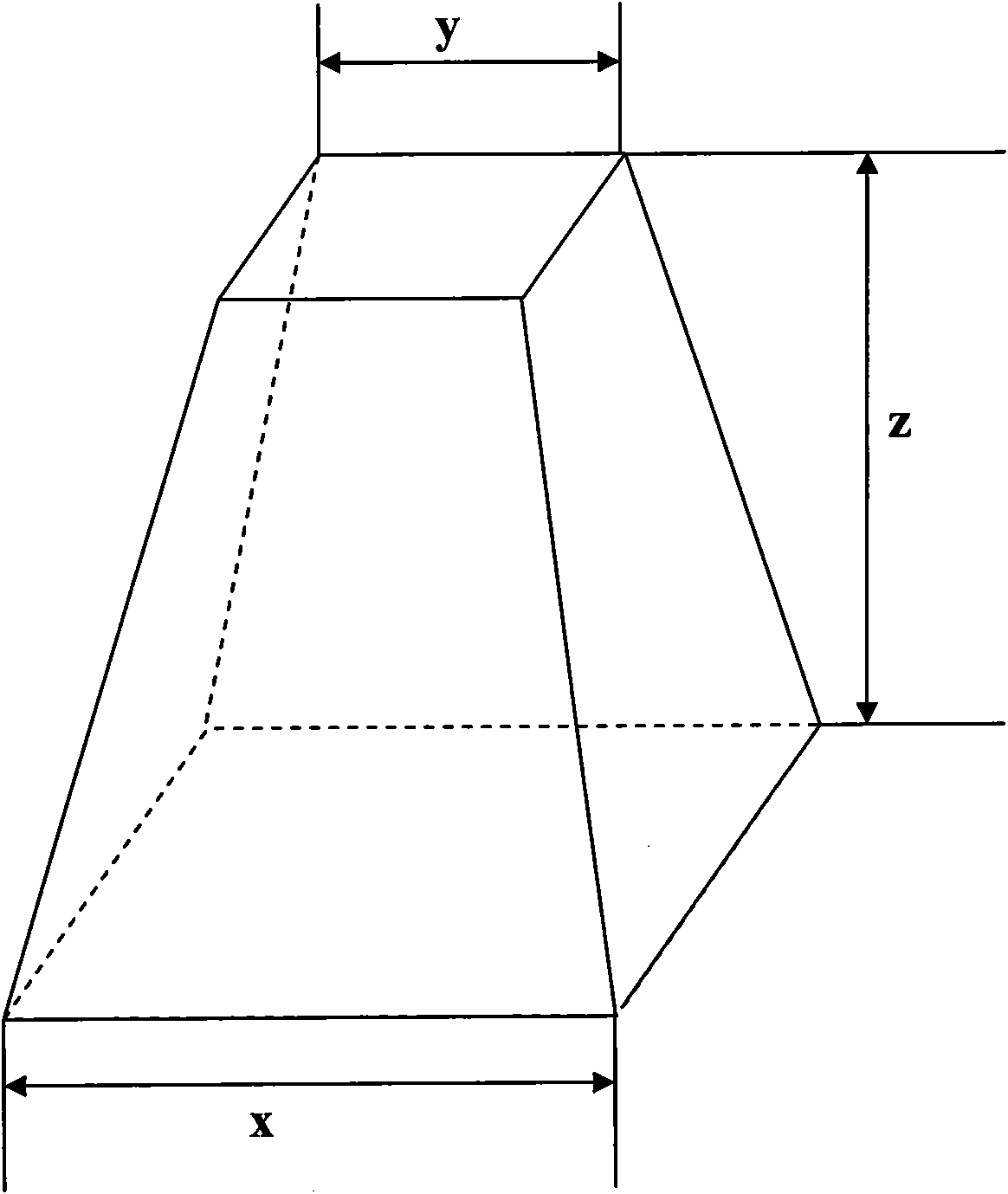

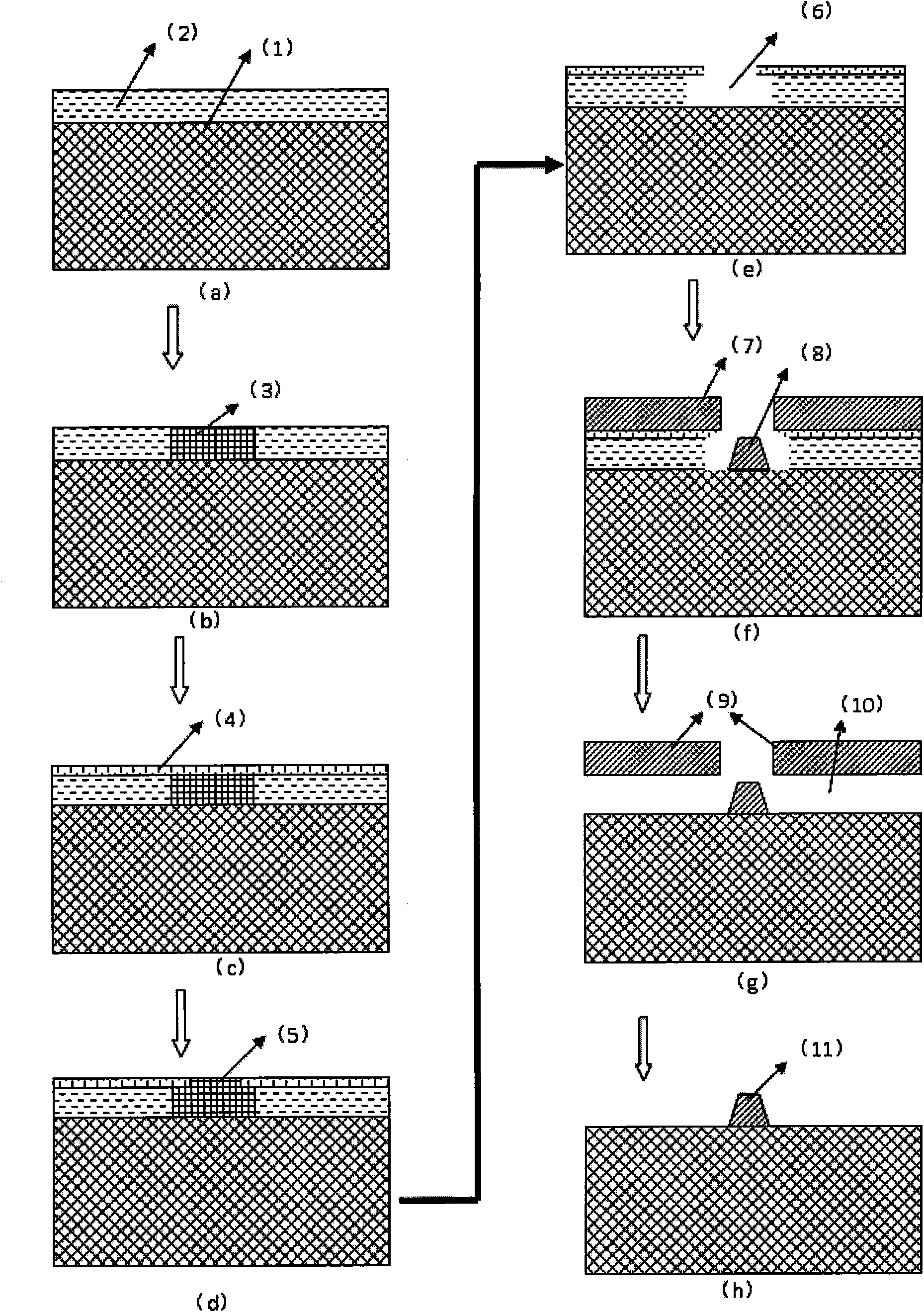

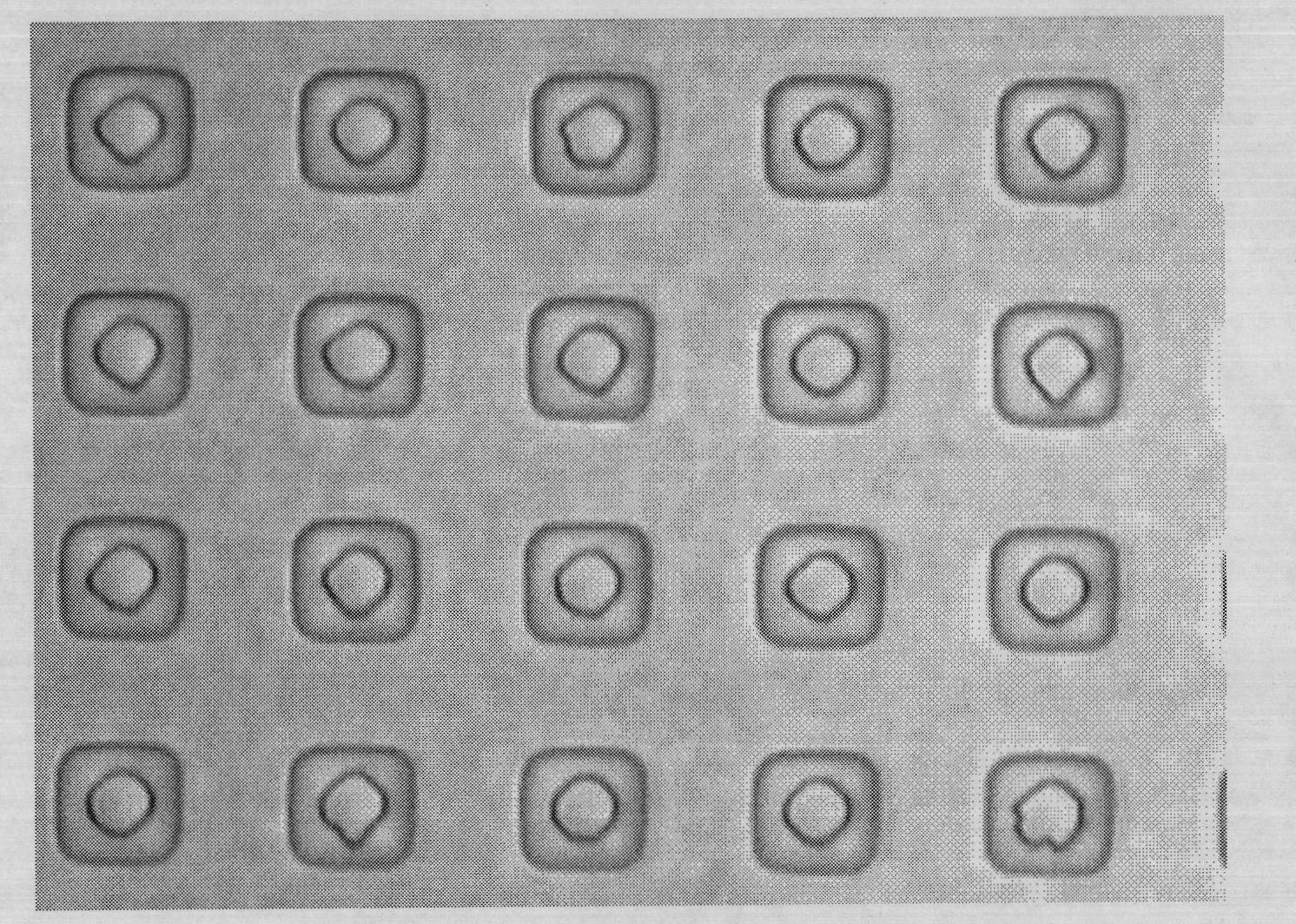

[0027] Below in conjunction with the accompanying drawings, the embodiment of the present invention will be described in detail by taking a chip with a center-to-center distance of 20 microns and an indium column array of 320x240 as an example:

[0028] In an embodiment of the present invention, a mercury cadmium telluride infrared chip on which a gold layer has been grown is used to grow an array of indium pillars. The preparation method of the indium column described in the present invention refers to performing two times of spin-coating photoresist on the mercury cadmium telluride infrared chip that needs to prepare the indium column, two separate exposures, and one development method to carry out the photoresisting of the indium column hole. When the indium layer is deposited by high-vacuum thermal evaporation, it is ensured that the chip is directly above the indium evaporation source. After the indium layer is grown, an organic reagent wet stripping method is used to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com