Ball-shape drum washing machine

A drum washing machine, spherical technology, applied in the field of washing machines, can solve the problems of relatively complicated structure, heavy drying rotating parts, small falling distance, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

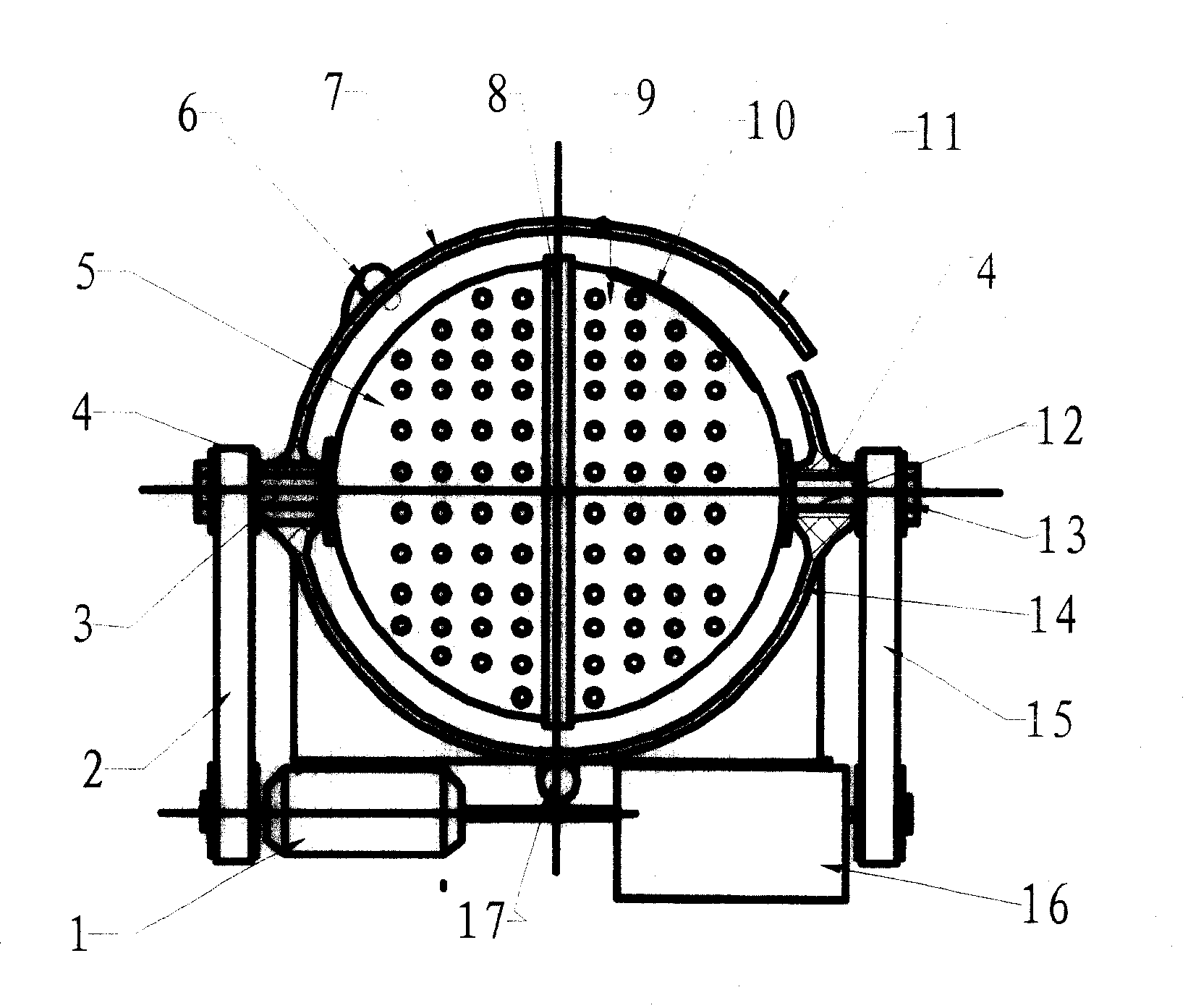

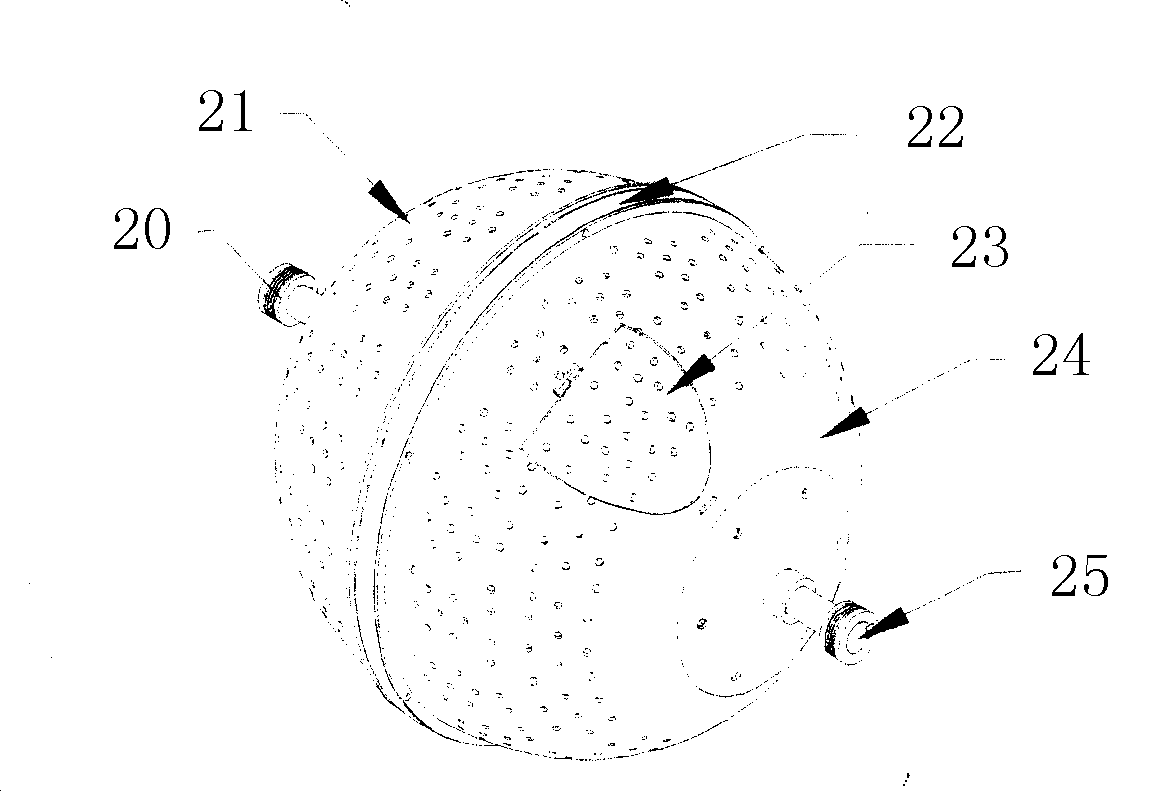

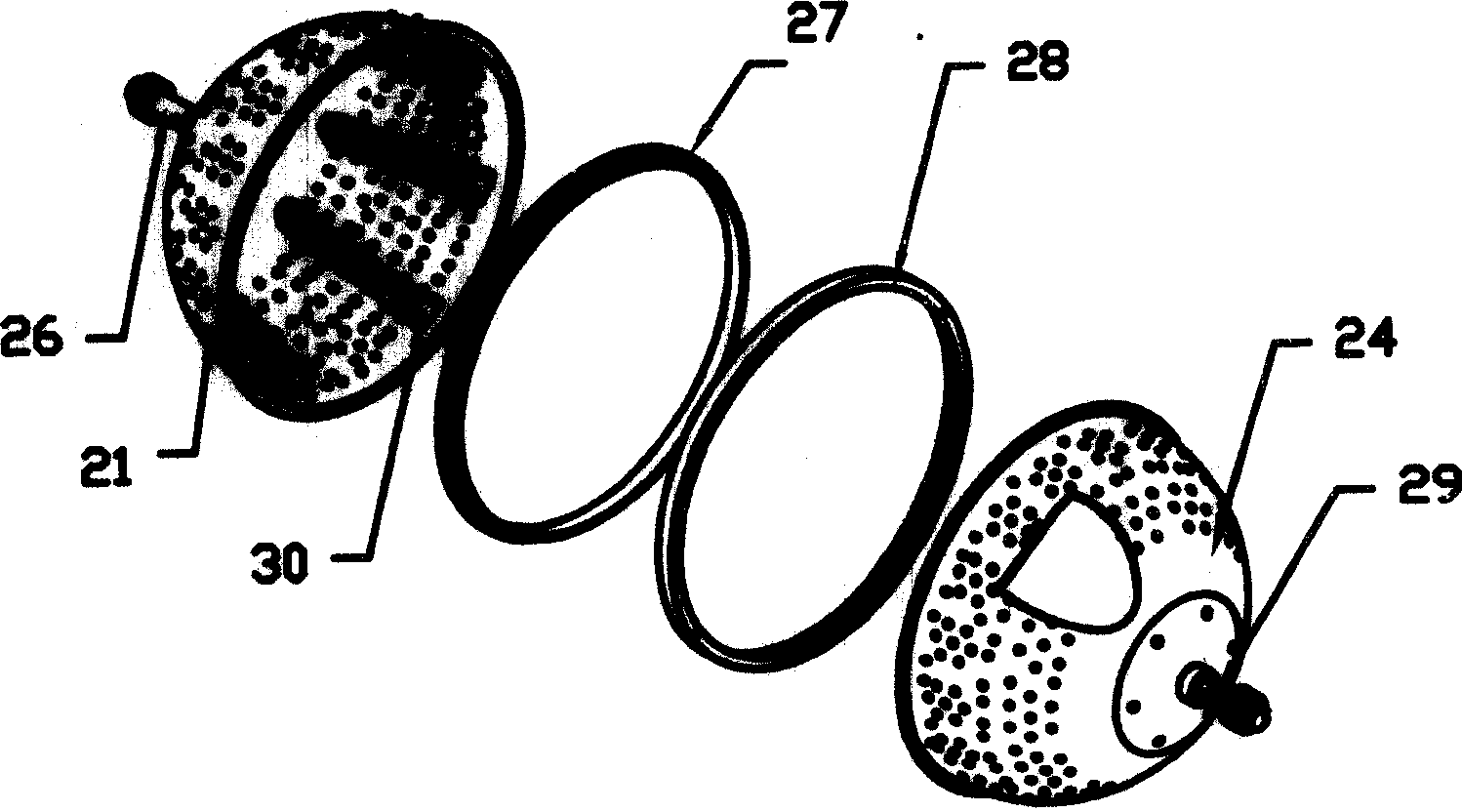

[0026] The composition of the whole machine structure of the present invention includes: motor 1, transmission belt and pulley 2 and 15, reversing speed box 16, left and right minor shafts 3 and 12, left and right hemispherical shells 5 and 9, hemispherical connecting bearings 8, upper , lower housing 7 and 14, inlet and outlet 6 and 17, support bearing 4, ball drum door 10 or 23, loam cake door 11 and belt wheel fastener 12; As the characteristic parts of the present invention, its spherical drum comprises Left and right hemispherical shafts and pulleys, left and right hemispherical shells 21 and 24 or 5 and 9, connecting bearing 22, ball roller door 23 or 10, left and right short shafts 26 and 29 or 3 and 12, inside the roller bearing, The outer rings 28 and 27 are combined with the inner rib 30 of the drum.

[0027] The design structure of the present invention is a cubic column with a spherical top, and the opening for taking and placing clothes is on the spherical surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com