FRP (Fiber Reinforce Plastic) profile connecting node and method

A technology for connecting nodes and connecting methods, applied in building materials, building material processing, construction, etc., can solve problems such as inability to guarantee quality, inability to achieve common stress, low joint efficiency, etc., and achieve fatigue resistance, air stability, good Air stability, the effect of improving shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The FRP profile connecting method of the present invention specifically comprises the following steps:

[0039] First of all, use a grinder to grind off the anti-skid coating of the overlapping section of profile 1. When grinding, care should be taken to control the grinding depth, preferably 0.5mm±0.1mm.

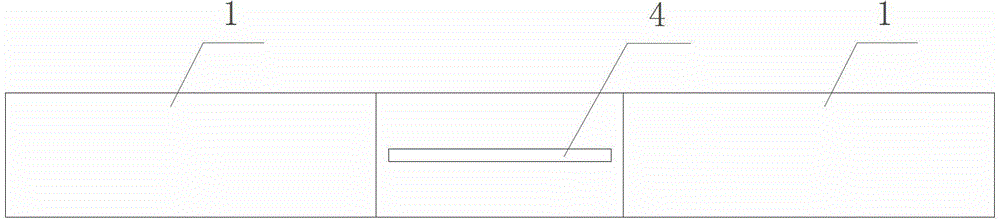

[0040] Secondly, mark the position and size of the binding groove 4 on the overlapping section of the profile 1, punch a hole in the marked binding groove 4 with a puncher, then process the binding groove 4 with a jigsaw or a manual saw, and then use a wooden file on the A chamfer with a radius of 3 mm ± 0.5 mm is ground on the edge of the groove to facilitate the stress of the untwisted fiber 4 .

[0041] Thirdly, apply epoxy resin impregnating glue to the overlapping position of the profiles to bond the two FRP profiles together.

[0042] Fourth, if manual winding is used, the untwisted fiber 3 must be put into the epoxy resin impregnating glue for not less than 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com