Nanopore grapheme, its preparation method and application

A graphene and nanopore technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as inability to stably disperse, and achieve the effects of rapid method, increased carboxyl group content, and easy preparation and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

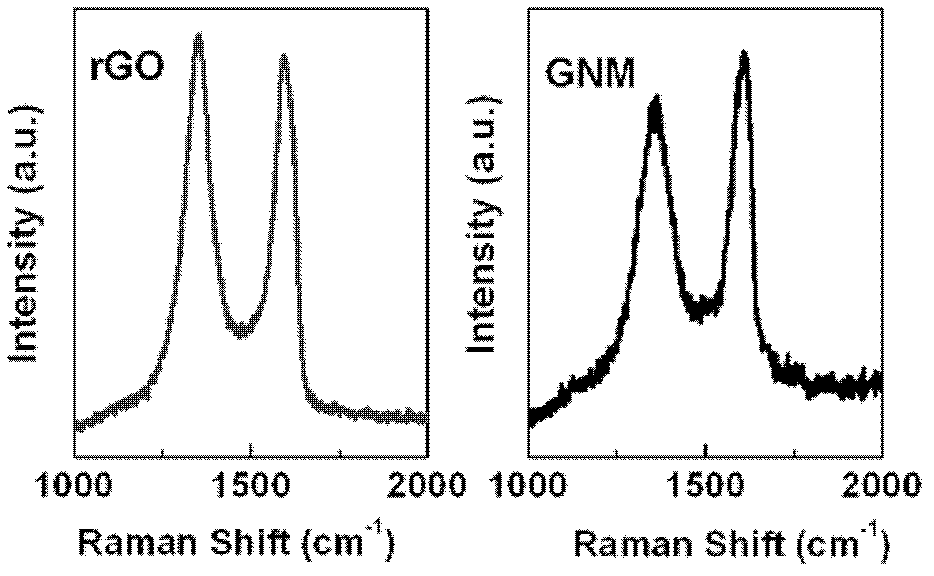

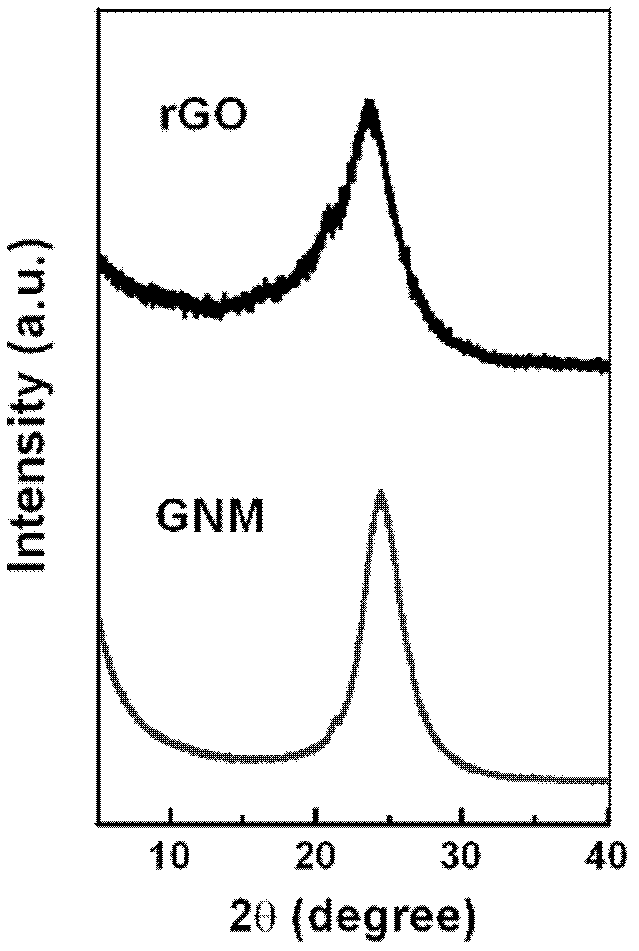

Image

Examples

Embodiment 1

[0032] The aqueous dispersion of chemically converted graphene with a concentration of 0.25 mg / mL was refluxed in 8M nitric acid solution at 100° C. for 12 hours, filtered by suction and washed with water until neutral to obtain the nanoporous graphene provided by the present invention.

[0033] Wherein, the graphene of described chemical conversion is prepared according to the following method:

[0034] 1) Preparation of graphene oxide: 3.3g of natural graphite powder (325 mesh), 1.5g of sodium nitrate and 70ml of 98wt% concentrated sulfuric acid were mixed in an ice-water bath, and after stirring evenly, 9.0g of potassium permanganate was slowly added. Raise the temperature of the system to 35°C, keep it stable for half an hour, add 150ml of deionized water, stir at 90°C for 15 minutes, add 500ml of deionized water, 15ml of 30wt% H 2 o 2 aqueous solution. The resulting bright yellow solution was filtered and washed with 250 mL of 1:10 aqueous HCl. The obtained solid was d...

Embodiment 2

[0043] The aqueous dispersion of chemically converted graphene with a concentration of 0.25mg / mL was refluxed in 16M aqueous nitric acid solution at 100°C for 12h, filtered by suction and washed with water until neutral to obtain the nanoporous graphene provided by the present invention.

[0044] Wherein, the graphene of described chemical conversion is prepared according to the following method:

[0045] 1) Preparation of graphene oxide: 3.30g of natural graphite powder (325 mesh), 1.5g of sodium nitrate and 70ml of 98wt% concentrated sulfuric acid were mixed in an ice-water bath, and after stirring evenly, 9.0g of potassium permanganate was slowly added. Raise the temperature of the system to 35°C, keep it stable for half an hour, add 150ml of deionized water, stir at 90°C for 15 minutes, add 500ml of deionized water, 15ml of 30wt% H 2 o 2 aqueous solution. The resulting bright yellow solution was filtered and washed with 250 mL of 1:10 aqueous HCl. The obtained solid was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com